Plaster

A patch and patch technology, applied in medical science, plant raw materials, bandages, etc., can solve the problems of reduced shape-forming ability, reduced adhesion, reduced strength, etc., to prevent loss and content reduction, keep shape unchanged, Prevents the effects of physical changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

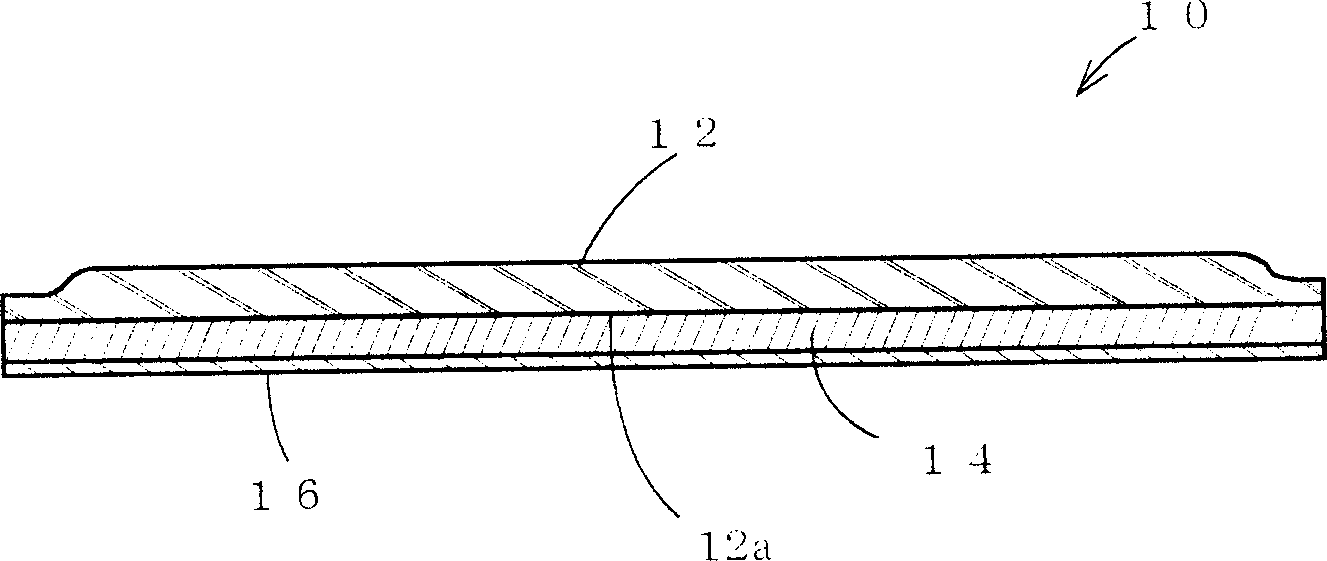

Image

Examples

Embodiment 1

[0036] The patch in the first embodiment of the present invention will be described in detail below. The patch in this embodiment is a cataplasm with a cooling effect, and its formula is shown in Table 1. As a comparison, the cataplasm formulations of the prior art are shown in Table 2.

[0037] The patch in this embodiment uses trehalose at a content of 0.5-10.0%, and its drug effect is stable without discoloration. The gel after adding trehalose becomes a microgel with a water content as high as 70-85%, so even if the amount of polyacrylic acid and CMCNa is reduced, good adhesion can be obtained. In addition, the paste used in combination with trehalose has fast spreading speed and low manufacturing cost.

[0038]Manufacturing method: Weigh tartaric acid, purified water, glycerin, kaolin, CMCNa, titanium oxide, sodium polyacrylate, trehalose and mix and stir for 30 minutes, then evenly add Tween-80, synthetic menthol, methyl salicylic acid, Sorbitan sesquioleate and anhyd...

Embodiment 2

[0042] Next, the patch in the second embodiment of the present invention will be described in detail. The patch in this example is a cataplasm with a warming effect, and its formulation is shown in Table 3. As a comparison, the formulations of cataplasms with warming effect in the prior art are shown in Table 4.

[0043] Formula example of cataplasm with warming effect of the present invention

[0044] Prescription examples of cataplasms with warming effect in the prior art

Embodiment 3

[0046] The patch in the third embodiment of the present invention will be described in detail below. The patch in this example is used as a cooling patch, and its formulation is shown in Table 5. As a comparison, the formula of the cooling patch in the prior art is shown in Table 6.

[0047] Manufacturing method: Weigh tartaric acid, purified water, sodium polyacrylate, trehalose, sodium acrylate polymer and glycerin and mix and stir for 30 minutes, then evenly add dipropylene glycol, synthetic menthol, paraben and anhydrous Aluminum hydroxide, then spread evenly at 80g / m 2 On the polyester non-woven fabric, the paste weight is 2500g / m 2 , and then press the polypropylene film, and finally cut it into a size of 50mm×130mm and seal it with an aluminum foil bag to obtain a film with excellent cooling performance.

[0048] Example of patch formulation for cooling of the present invention

[0049] Conventional chip formulation example for cooling

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com