Labyrinth type current-crossing and bubbling photocatalytic reaction device and method for treating organic waste water thereby

A photocatalytic reaction and photocatalytic reactor technology, which is applied in the field of high-efficiency photocatalytic reaction devices and organic wastewater treatment fields, can solve the problems of difficult recovery and regeneration of catalysts, reducing the effective volume of the reactor, and low reactor efficiency, etc. Effective utilization, simple structure, effect of increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

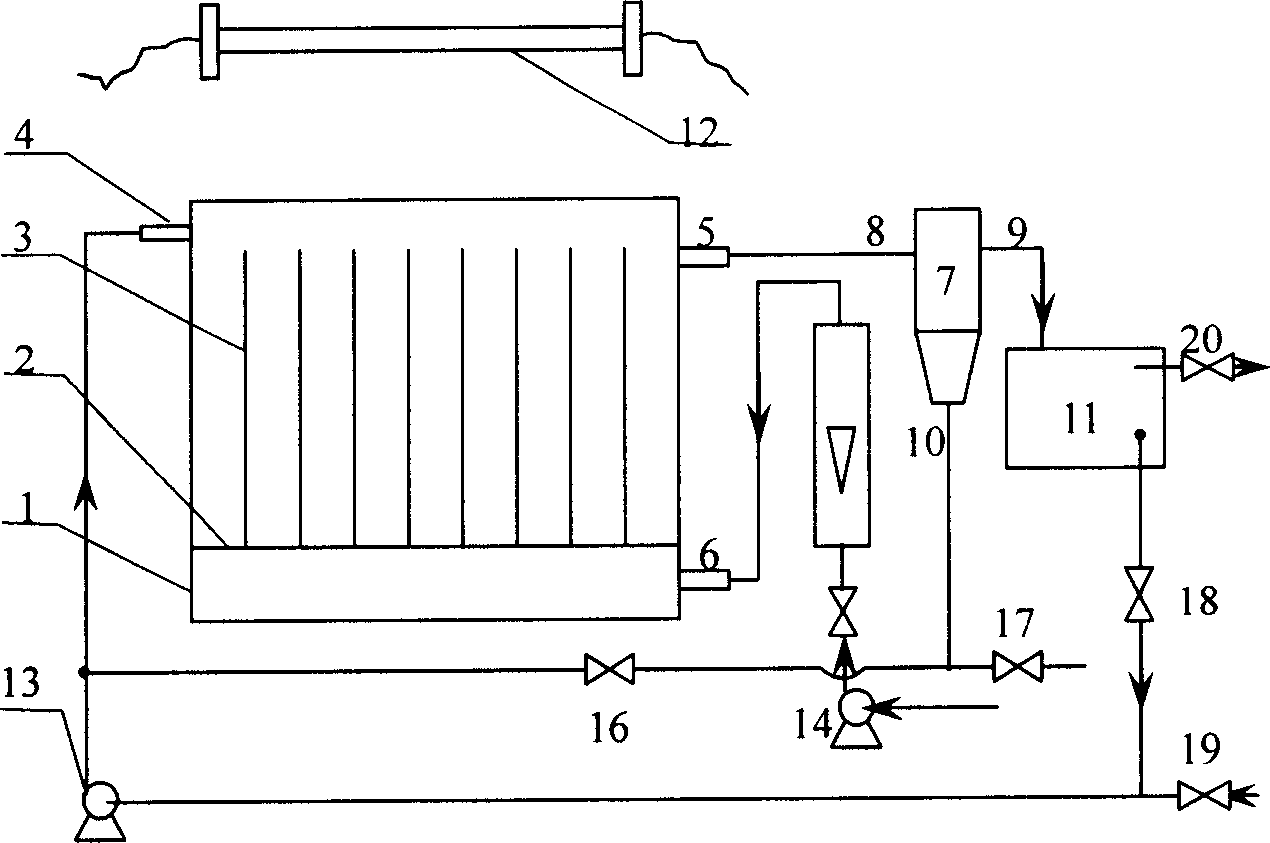

[0022] The device of the present invention is mainly composed of a main body of a labyrinth cross-flow bubbling photocatalytic reactor 1 , an external solid-liquid separator 7 , a circulation system and a parallel light source 12 above the reactor 1 .

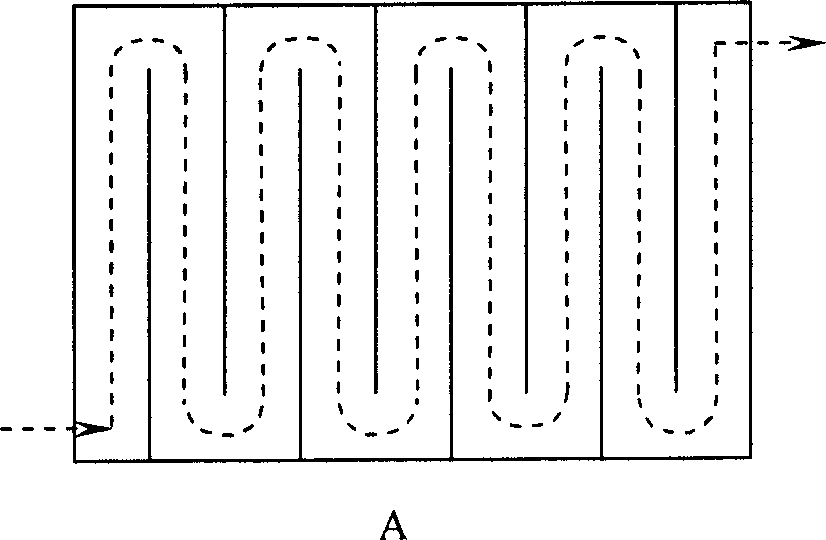

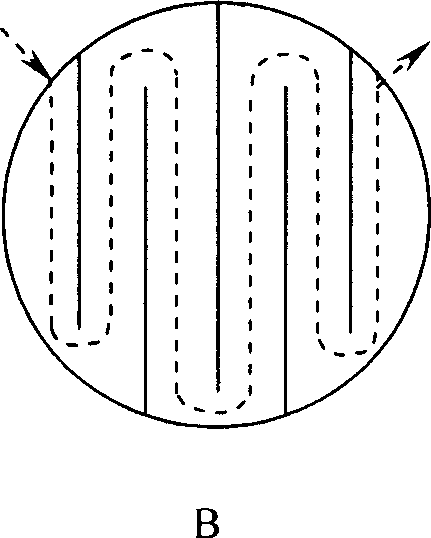

[0023] The cross section of the main body of the reactor 1 of the present invention is circular or rectangular. A porous gas distribution plate 2 is installed in the reactor 1. The gas pre-distribution section is located below the distribution plate 2 and the reaction zone is located above it. A plurality of parallel baffles 3 are vertically arranged above the internal distribution plate 2 of the reactor 1 to form a liquid phase labyrinth channel. The parallel baffles 3 are rectangular, and the lower end is fixed on the parallel distribution plate 2. One end of the side of the parallel baffles 2 is connected and fixed with the wall of the reactor 1, and the other end is kept at a certain distance from the wall of the reactor 1 t...

Embodiment 2

[0025] A method for treating organic wastewater with a labyrinth cross-flow bubbling photocatalytic reaction device is as follows:

[0026] (1) Photocatalytic degradation of phenol wastewater by gap cycle operation

[0027] figure 1 As shown in, the supported TiO with granular activated carbon as the carrier 2 (Germany Degussa P25, which is loaded on the surface of granular activated carbon by impregnation method to make TiO 2 Support film, TiO 2 The amount of active components is about 0.2%wt of the amount of liquid to be treated) The photocatalyst is put into a circular reactor 1 with an effective volume of 0.8L, and 1000mL of simulated organic wastewater with an initial concentration of phenol of 20mg / L is added in the circulating water tank 11 , a 375W high-pressure mercury lamp is used to generate a parallel light source through the reflection of the lampshade, and the light intensity at the liquid surface of reactor 1 is 8mW / cm 2. Open the valve 18, and the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com