Method of extracting qinghaosu

A technology of artemisinin and cyclic extraction, which is applied in the direction of organic chemistry, can solve the problems of long time, low extraction rate, and large amount of organic solvents, so as to reduce environmental pollution, reduce the number of recrystallization times, and increase the overall yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

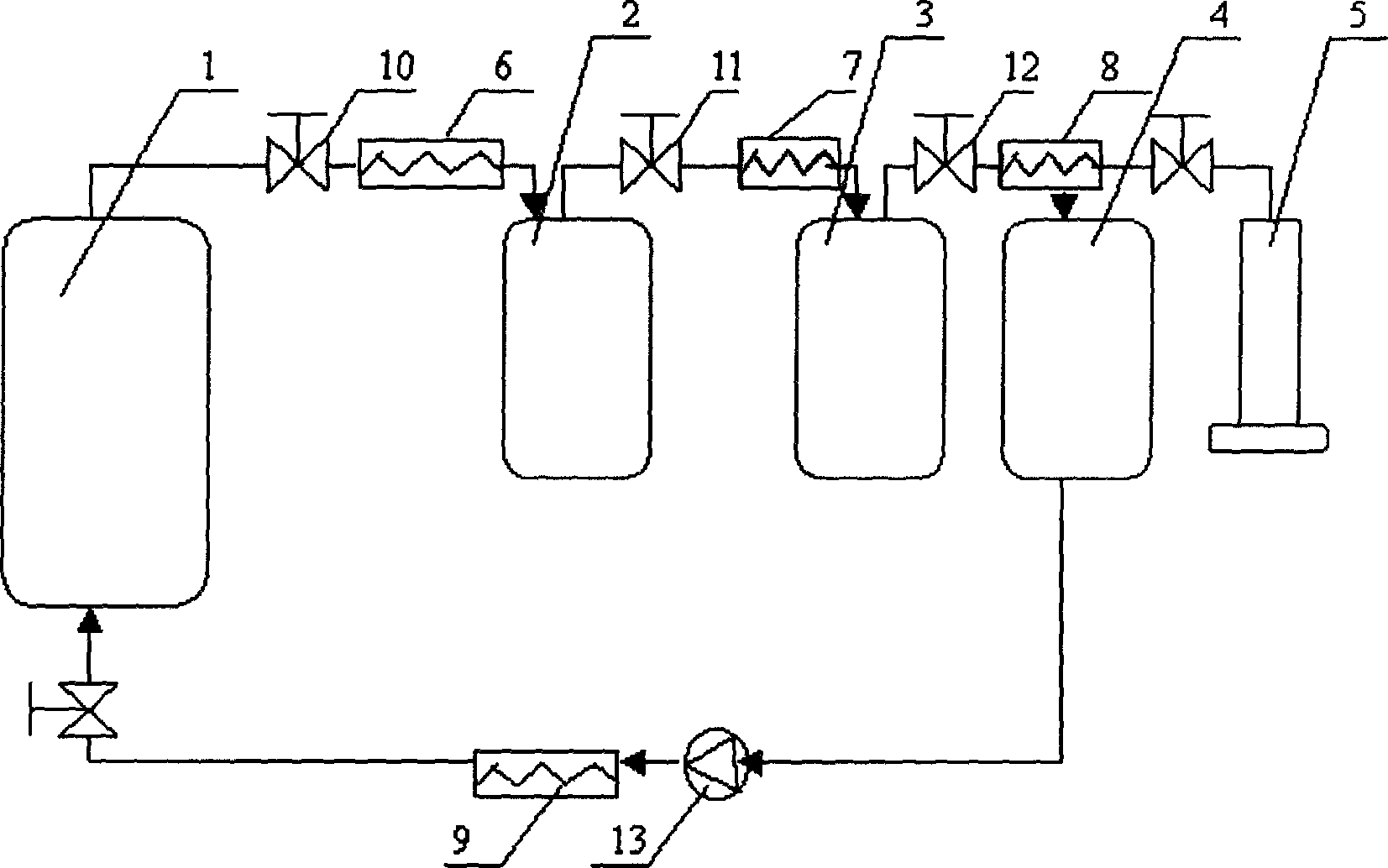

Image

Examples

Embodiment 1

[0016] The dried Artemisia annua raw material was pulverized, sieved and weighed 2 kg into the extraction kettle 1, and the temperature control of the extraction kettle 1 and the analysis kettles 2 and 3 was started after the materials were loaded. When the extraction temperature reaches 10°C and the temperature of the analysis kettle 2 and 3 reaches 40°C, pressurization is started, and the CO 2 Pressurize the extraction kettle 1 and the desorption kettle 2, 3 at a flow rate of 0.62L / min, start extraction when the extraction kettle 1 reaches 15MPa and the desorption kettle 2, 3 reaches 6MPa, and through the control of the pressure regulating valve 10, 11, Keeping the above parameters constant, after 5 hours of extraction, shut down and discharge to obtain 93g of crude artemisinin, wherein the content of artemisinin is 15.8%. The crude product was then crystallized from aqueous ethanol. The purity is 99.5%. The yield of the whole process is 92.6%.

Embodiment 2

[0018] Operated in the same manner as Example 1, throwing 2 kg of Artemisia annua, extracting for 5 hours at an extraction pressure of 15 MPa, a separation pressure of 6 MPa, an extraction temperature of 15 °C, a separation temperature of 35 °C, and a CO2 flow rate of 0.62 L / min, to obtain 97 g of crude artemisinin, of which Artemisinin content is 15.4%. The artemisinin fine product was obtained by recrystallization with aqueous methanol, with a purity of 99.6% and an extraction rate of 93.2% in the whole process.

Embodiment 3

[0020] Operated in the same manner as in Example 1, throwing 2 kg of Artemisia annua, extracting for 5 hours at an extraction pressure of 25 MPa, a separation pressure of 6 MPa, an extraction temperature of 5 ° C, a separation temperature of 45 ° C, and a CO2 flow rate of 0.62 L / min, to obtain 93 g of crude artemisinin, of which Artemisinin content is 16.1%. The refined artemisinin was obtained by recrystallization with ethanol aqueous solution, the purity was 99.8%, and the extraction rate of the whole process was 94.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com