Thin-wall bimetal self-lubricating bearing and manufacturing method

A self-lubricating bearing and manufacturing method technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of high cost and low mechanical strength, and achieve the effects of light weight, improved mechanical strength, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

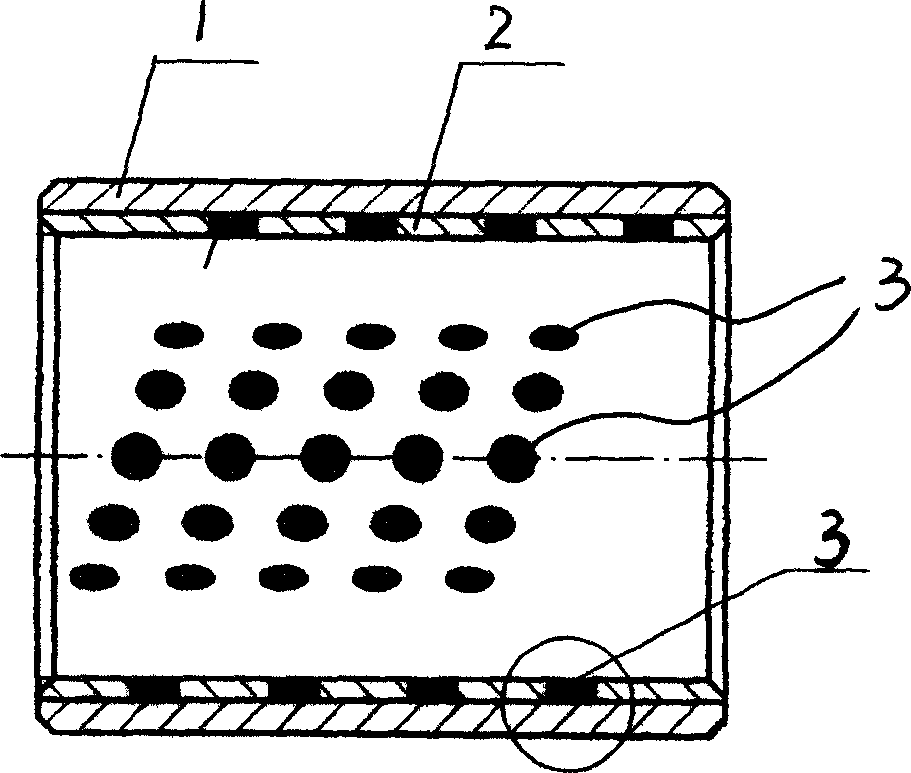

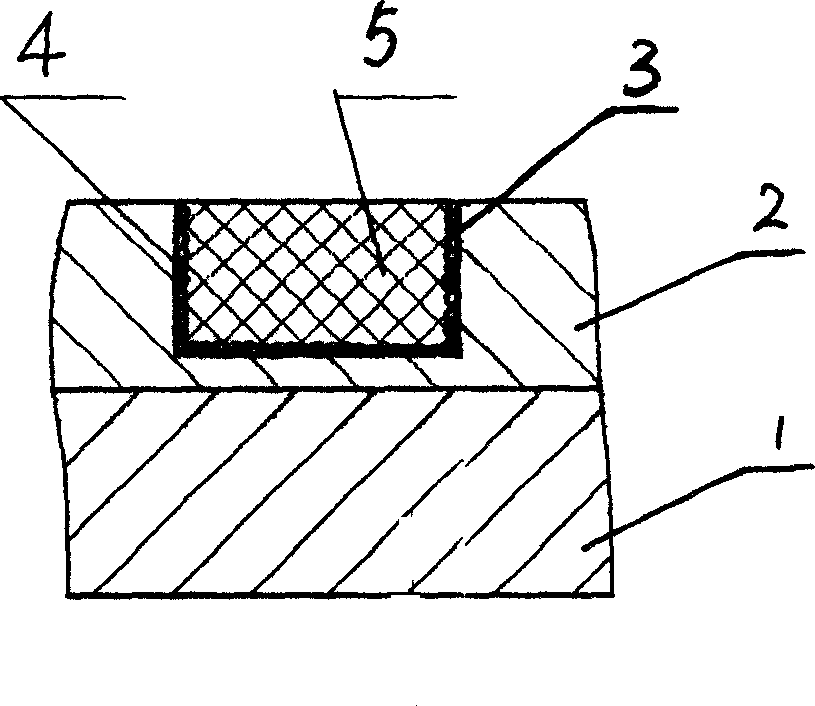

[0020] a. Spread 150-250 mesh spherical or dendritic copper alloy powder uniformly on a steel plate or stainless steel plate 1 of 1 to 3 mm with a thickness of 0.5 to 2 mm. Use a hydrogen protection furnace or a vacuum furnace for sintering and rolling after sintering. Compound copper alloy layer 2 on steel plate or stainless steel plate 1;

[0021] b. Use drilling, punching or rolling on the copper alloy layer 2 to process blind holes that can be round, diamond, square, oval and other shapes. The depth of the blind hole 3 is 0.4~1.9mm, if yes For round holes, the hole diameter is 1.3-3.5mm, and the total surface area of the solid lubricant should be 25-35% of the copper alloy surface area.

[0022] c. Spray ammonium chloride solution evenly on the inner surface of the blind hole 3, then spread 40-150 mesh spherical tin bronze powder on the ammonium chloride solution, use a hydrogen protection furnace or a vacuum furnace to sinter the copper powder, and then chlorinate after sin...

Embodiment 2

[0026] Others are the same as in embodiment 1, except that step a is to spray 150-250 mesh spherical or dendritic copper alloy powder on the steel plate or stainless steel plate 1, that is, compound the copper alloy layer 2 on the steel plate or stainless steel plate 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com