Diplopore silica gel material, and preparation method

A technology of silica gel column and pore size, which is applied in the direction of silica, silica, etc., can solve the problems of application limitation, insufficient mechanical strength of silica gel integral column, etc., and achieve the effect of improving mechanical strength and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 4.97g of polyethylene glycol (molecular weight: 10,000) into 52mL of 0.01mol / L nitric acid, stir until completely dissolved, then add 28.4mL of tetramethoxysilane (TMOS), and stir vigorously at 0°C for 30 minutes , Pour the obtained sol into a polytetrafluoroethylene tube with a diameter of about 1.0 cm and seal it, and place it in a water bath at 40° C. for 2 hours to gel.

[0024] Secondly, take out the silica gel column in the polytetrafluoroethylene tube, wash it with deionized water, place it in a methanol solution with a volume ratio of 20% (water / methanol), and keep it at 55° C. for 24 hours. Then placed in a methanol solution of TMOS with a volume ratio of 65% (TMOS / methanol), aged at 65° C. for 60 hours. Then soak in methanol at 50°C for 24 hours. Finally, dry at 70°C for 24 hours, and bake at 700°C for 2 hours to obtain a silica gel column sample.

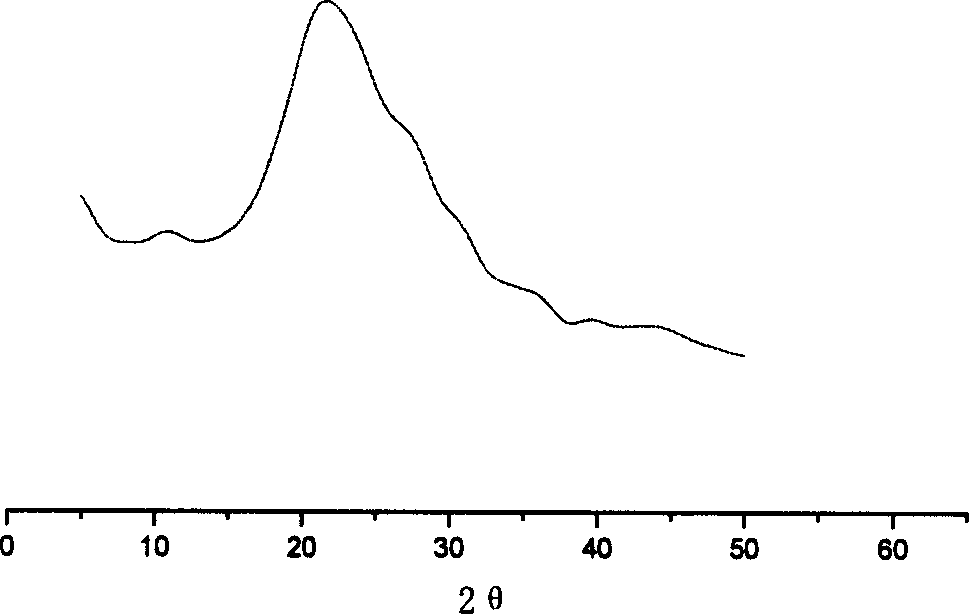

[0025] figure 1 is the SEM image of the obtained sample, figure 2 is the X-ray diffraction pattern of t...

Embodiment 2

[0028] Add 4.97g of polyethylene glycol (molecular weight: 100,000) into 52mL of 0.01mol / L acetic acid, stir until completely dissolved, then add 28.4mL of tetramethoxysilane (TMOS), and stir vigorously at 0°C for 30 minutes , Pour the obtained sol into a polytetrafluoroethylene tube with a diameter of about 1.0 cm, seal it, and place it in a water bath at 40° C. for 3 hours to gel.

[0029] Next, take out the silica gel column in the polytetrafluoroethylene tube, wash it with deionized water, put it in an ethanol solution with a volume ratio of 18% (water / ethanol), and keep it at 62.5° C. for 24 hours. Then placed in a TMOS ethanol solution with a volume ratio of 59% (TMOS / ethanol), aged at 65° C. for 96 hours. Then soak in ethanol at 50°C for 24 hours. Finally, dry at 60°C for 48 hours, and bake at 700°C for 2 hours to obtain a silica gel column.

[0030] image 3 It is a scanning electron microscope photo of the obtained sample. The macropore diameter of the sample is 1....

Embodiment 3

[0032] Add 4.37g of polyethylene glycol (molecular weight: 10,000) into 52mL of 0.044mol / L nitric acid, stir until completely dissolved, then add 28.4mL of tetramethoxysilane (TMOS), and stir vigorously at 0°C for 30 minutes , Pour the obtained sol into a polytetrafluoroethylene tube with a diameter of about 1.0 cm and seal it, and place it in a water bath at 40° C. for 2 hours to gel.

[0033] Next, take out the silica gel column in the polytetrafluoroethylene tube, wash it with deionized water, place it in a methanol solution with a volume ratio of 26% (water / methanol), and keep it at 70° C. for 24 hours. Then placed in a methanol solution of TMOS with a volume ratio of 50% (TMOS / methanol), aged at 57.5° C. for 24 hours. Then soak in an aqueous solution of Tween 80 at 50°C for 24 hours. Finally, dry at 70°C for 24 hours, and bake at 700°C for 2 hours to obtain a silica gel column.

[0034] Figure 4 It is a scanning electron microscope photo of the obtained sample. The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com