Method for preparing oleanolic acid from wrinkled papaya

A technology of oleanolic acid and wrinkled papaya, applied in the field of fruit processing, can solve the problems of complex process, low purity, high cost, etc., and achieve the effect of simple process, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

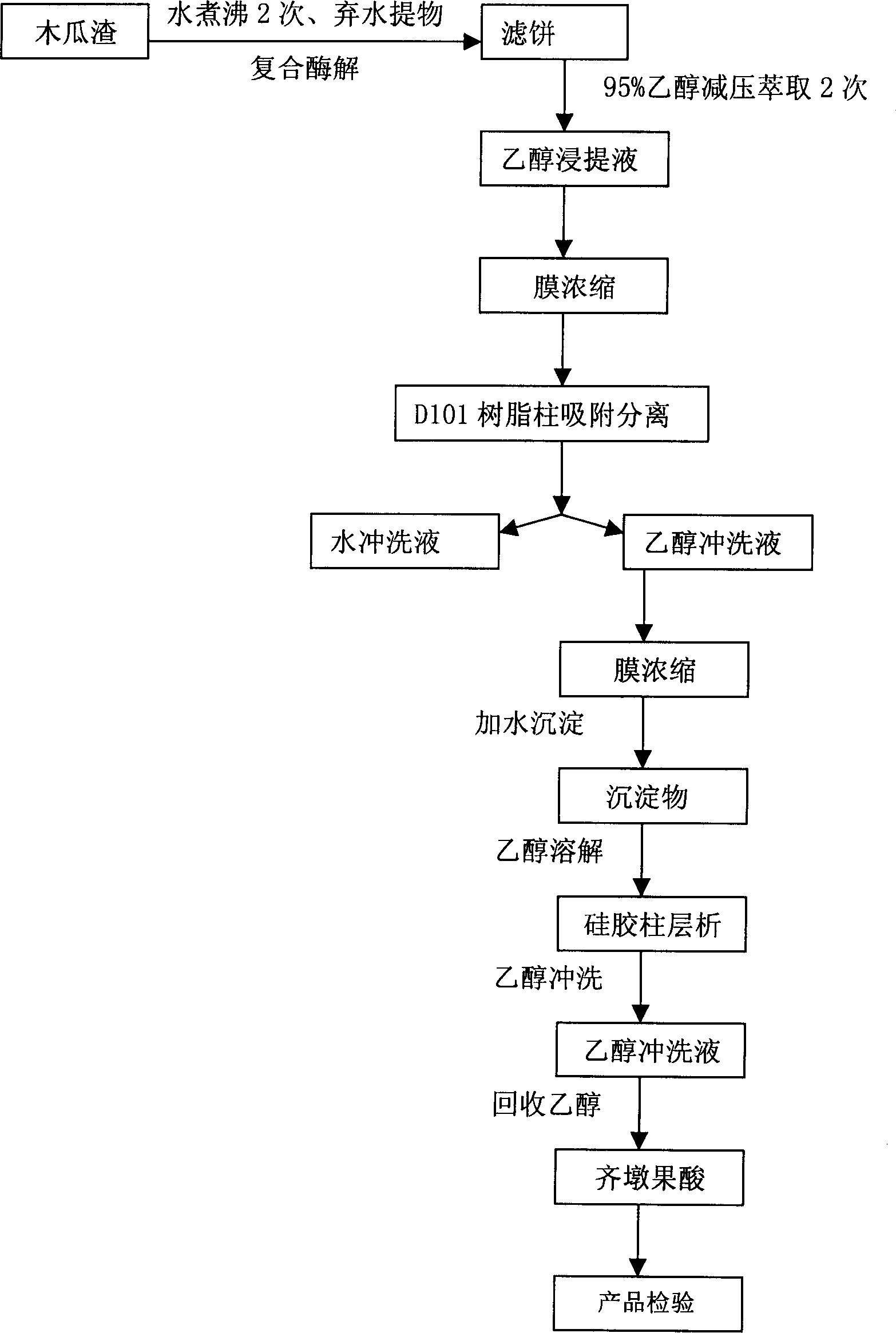

Image

Examples

Embodiment Construction

[0017] Using the papaya residue of 100 kg of fresh papaya (discarded seeds and flesh) as raw material, the extraction, separation and purification of oleanolic acid in papaya were carried out.

[0018] The specific process is as follows:

[0019] 1. Take papaya dregs with a particle size of 40 meshes after squeezing the juice, put them into water for 2 times of soaking in the ratio of 1:4 by mass percentage, each time for 3 hours; then soak for the third time in water according to the ratio of 1:3 by mass percentage , respectively adding the compound enzyme of pectinase, cellulase and hemicellulase (the ratio is 1:2:3, the addition is 1000u / 100 grams of papaya residue), and the temperature is 40 ℃ for enzymolysis for 3 hours , filter or squeeze after decomposing fiber and pectin, and filter cake or filter residue for later use;

[0020] 2. The filter cake was extracted with 95% ethanol at a ratio of 1:4 by mass percentage at a temperature of 40°C and a pressure of 0.065 atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com