Processes for fabricating conductive patterns using nanolithography as a patterning tool

A nano and pattern technology, applied in conductive pattern formation, nanotechnology, nanotechnology, etc., can solve problems such as electrochemical bias limitation and metal processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] Especially in the prior application 09 / 866533 filed on May 24, 2001 (references 7 and 8, 2002 / 0063212 A1 published on May 30, 2002), the background of direct-write nano-etching printing is disclosed in detail Technology and methods, including various implementations, such as: background technology (pages 1-3); summary of the invention (pages 3-4); brief description of the drawings (pages 4-10); scanning probe tip Use of (pages 10-12); substrates (pages 12-13); patterned compounds (pages 13-17); implementation methods, including, for example, tip coating (pages 18-20); including nanoplotters Instrumentation (page 20-24); multilayer application and related printing and etching methods (page 24-26); resolution (page 26-27); matrix and combination matrix (page 27-30); Software and scales (pages 30-35, 68-70); kits and components including tips coated with hydrophobic compounds (pages 35-37); working examples (pages 38-67); corresponding claims And summary (pages 71-82); and att...

Embodiment 1

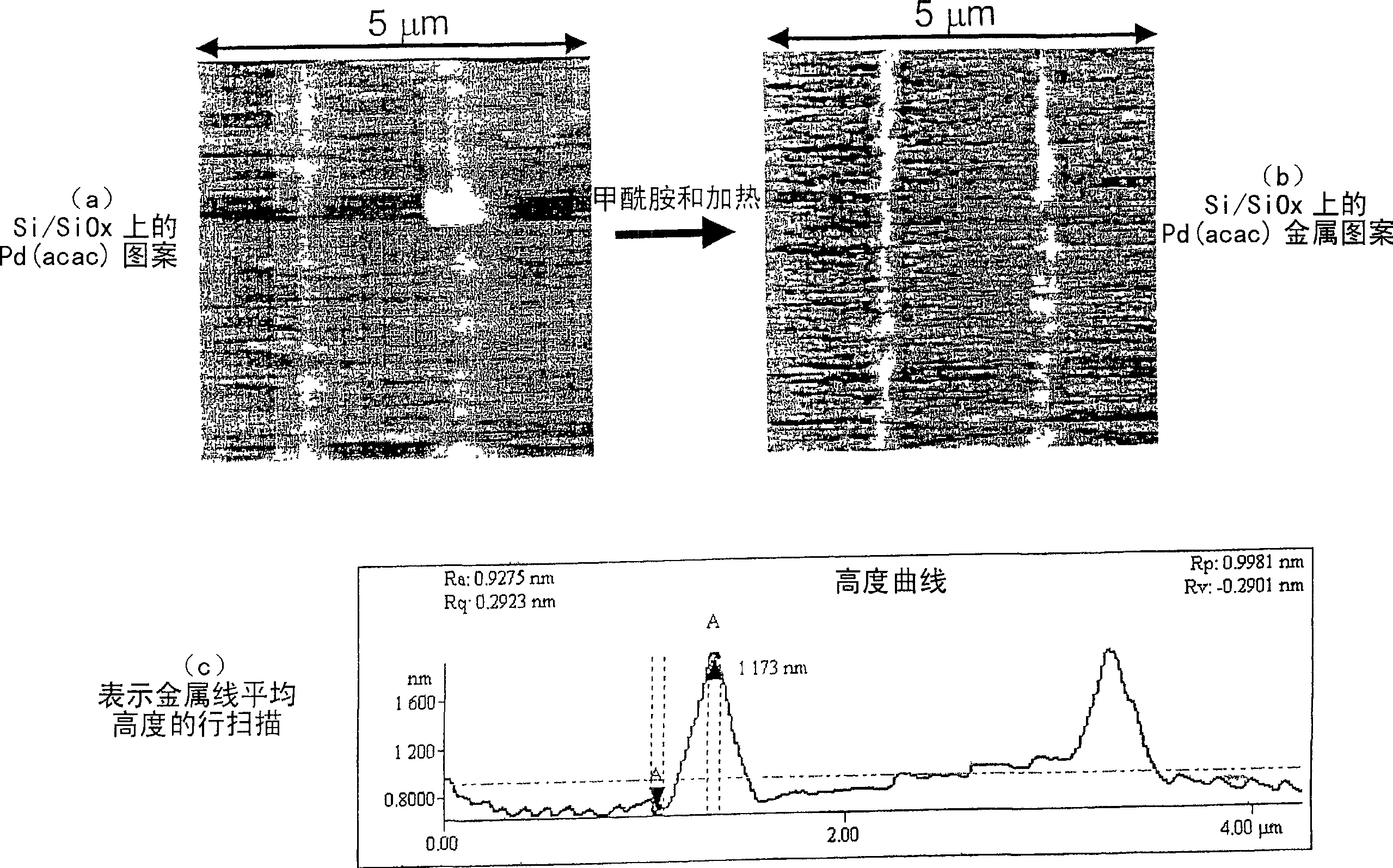

[0115] A specific example of this method is the use of DPN TM For printing or deposition patterning, palladium acetylacetonate dissolved in chloroform (1 mg / μl, usually requires an almost saturated ink solution) is patterned on oxidized silicon, glass or aminosilanized glass. After the dots are formed, a drop (1 microliter) of formamide is dropped on the horizontal substrate and heated to 150°C for 2 minutes. The resulting metal pattern remains stable to solvent (including water, alcohol and other non-polar organics) rinsing, and the salt pattern before reduction is removed by solvent rinsing. figure 1 Indicates that before using formamide and heat treatment ( figure 1 a) and after processing ( figure 1 b and figure 1 c) AFM image and pattern height scan.

Embodiment 2

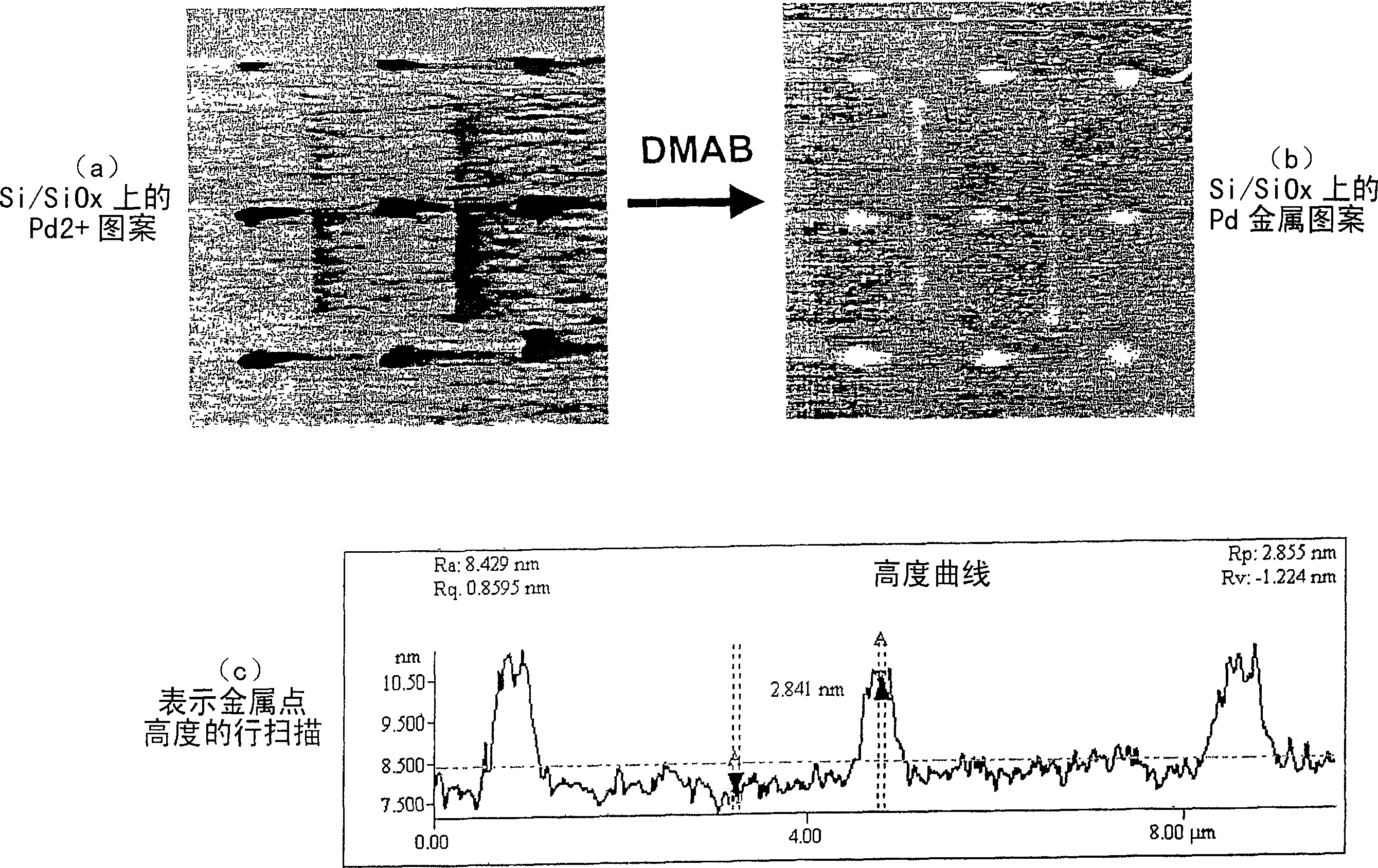

[0117] Palladium nanopatterns were deposited by DPN printing and metallized by steam reduction. The DPN ink was patterned on silicon oxide using DPN technology, and the ink consisted of a dimethylformamide solution of palladium acetate. The DPN pen used is a silicon nitride probe coated with gold. This method is very suitable for the use of aluminum-plated DPN probes, because the aluminum coating does not directly reduce the metal salt to the cantilever, while the gold-plated probe may directly reduce the metal salt to the cantilever. Before patterning, the silicon / silicon oxide wafer was sonicated and cleaned in microporous water for 5 minutes. The patterned substrate was placed vertically in a conical polyethylene tube, and 10 microliters of formamide liquid was placed at the bottom of the tube. The tube was placed on a heater and heated at 80°C for 30 minutes, so that the steam caused reduction of the metal precursor. Since this method protects the metal pattern on the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com