Taste masked pharmaceutical composition comprising pH sensitive polymer

A composition and polymer technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, block delivery, etc., can solve the problems of high dosage requirements and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

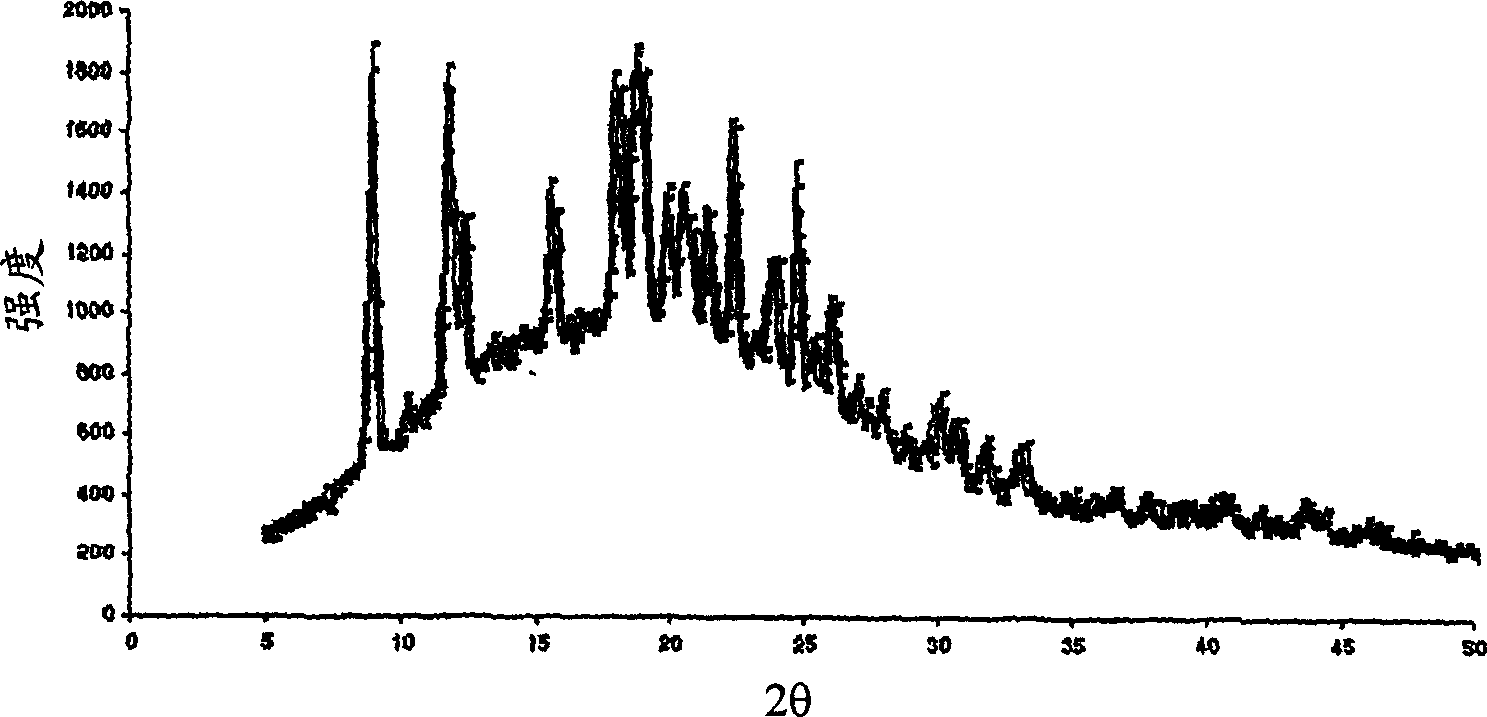

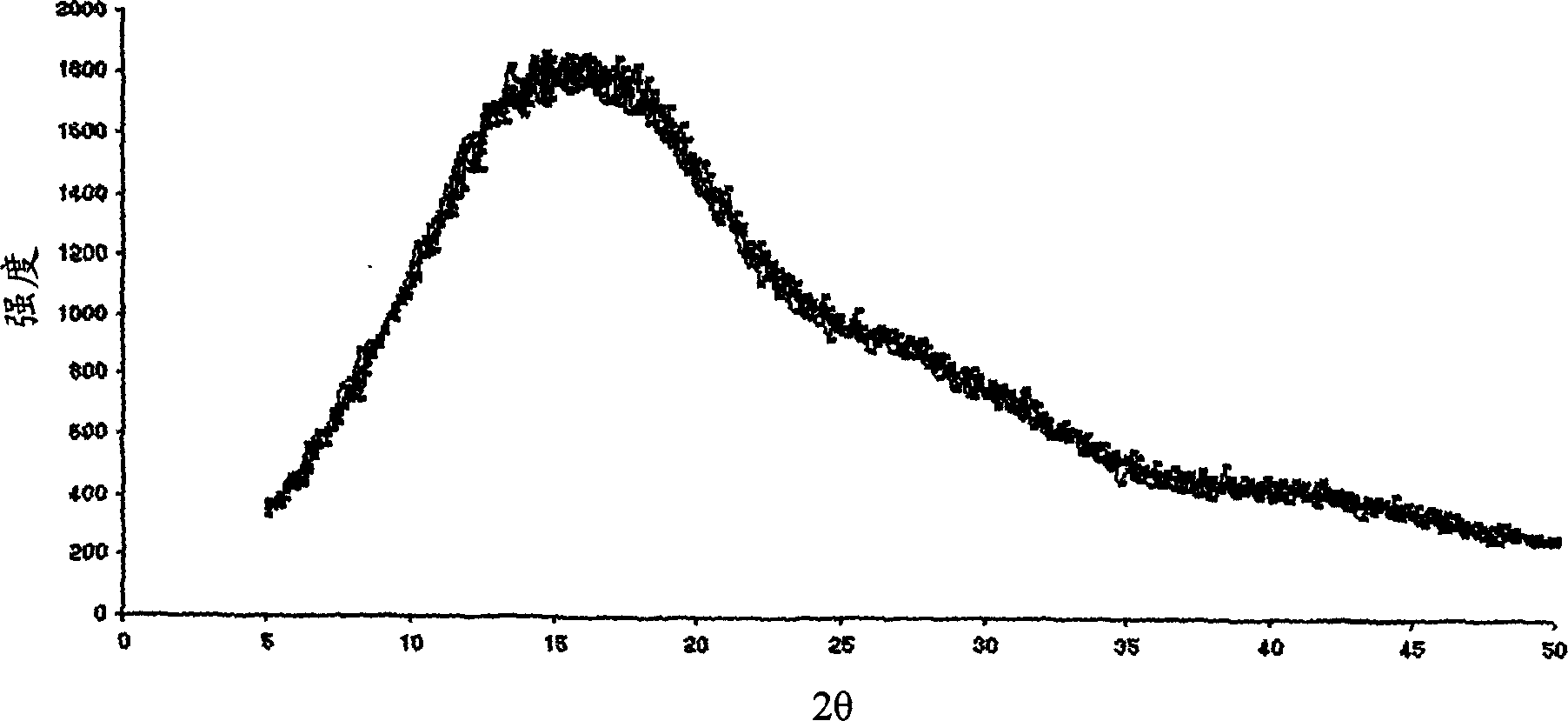

[0128] The pH sensitive polymers are synthesized by solution polymerization. 60% by weight of the hydrophobic monomer methyl methacrylate, 25% by weight of the hydrophilic monomer hydroxyethyl methacrylate, and 15% by weight of the basic monomer vinylpyridine are used for the synthesis of the polymer. These monomers are dissolved in the solvent dimethylformamide. The azo initiator, azobisisobutyronitrile, was added to the monomer solution in dimethylformamide. The reaction mixture was purged with nitrogen to provide an inert atmosphere. Polymerization was carried out by heating the reaction mixture to 65°C for 18 hours. The synthesized polymer is recovered by precipitation in a non-solvent. Use diethyl ether as a non-solvent. The polymer was vacuum dried at 27°C. Characterize the viscosity, molecular weight and composition of the polymer. The polymer compositions, molecular weights and intrinsic viscosities of the polymers are summarized in Table 1.

[0129] Nu...

Embodiment 2

[0132] The pH sensitive polymers used to inhibit crystallization of polymorphic drugs at lower polymer loadings are polymers with higher molecular weight and higher viscosity. The higher molecular weight polymer is made with 60% by weight of the hydrophobic monomer methyl methacrylate, 25% by weight of the hydrophilic monomer hydroxyethyl methacrylate, and 15% by weight of the basic monomer vinylpyridine , and synthesized by changing the amount of initiator and solvent. Higher molecular weight polymers can also be synthesized by reducing the concentration of initiator relative to the monomer content. Alternatively, higher molecular weight polymers can be synthesized by reducing the amount of inert solvent to the monomer content.

[0133] The high molecular weight pH sensitive polymers of the present invention are synthesized by solvent polymerization. The hydrophobic monomer methyl methacrylate, the hydrophilic monomer hydroxyethyl methacrylate, and the basic monomer vinylpy...

Embodiment 3

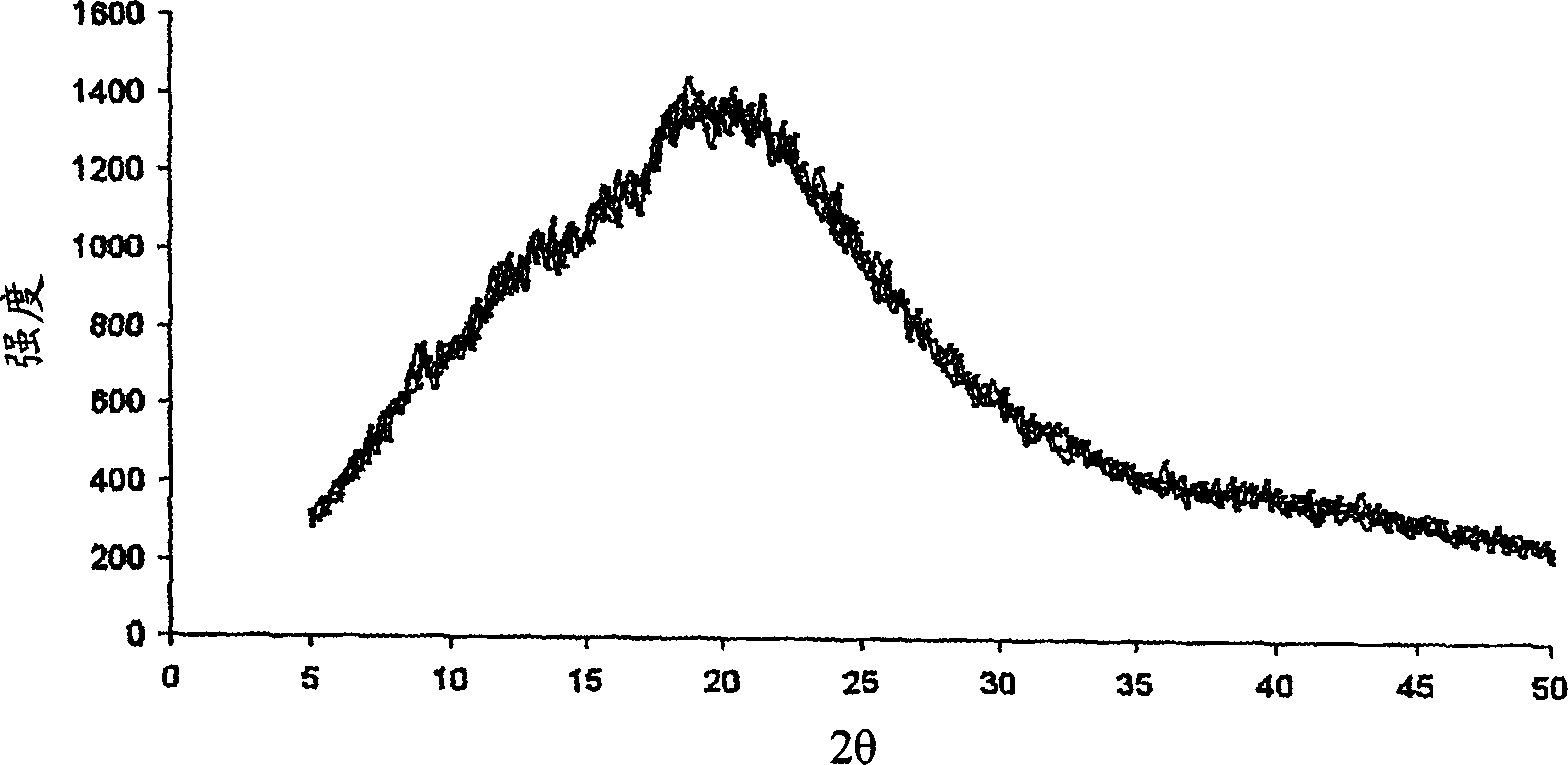

[0138] Using a monomer composition of 60% weight / weight (w / w) methyl methacrylate, 25% weight / weight (w / w) hydroxyethyl methacrylate and 15% weight / weight (w / w) Vinylpyridine, 51% by weight (accounting for the monomer) of dimethylformamide as a solvent, and 0.0225% of azobisisobutyronitrile as an initiator to synthesize a high molecular weight polymer. The polymerization reaction is carried out by heating the reaction mixture to 60-70°C for 15-18 hours. The synthesized polymer was recovered by precipitation in the non-solvent diethyl ether. The polymer was dried under vacuum at 27°C. The polymer compositions are shown in Table 3.

[0139] Using a monomer composition of 60% weight / weight (w / w) methyl methacrylate, 25% weight / weight (w / w) hydroxyethyl methacrylate and 15% weight / weight (w / w) Vinylpyridine, with dimethylformamide of 34.72% by weight (accounting for monomer) as solvent, and azobisisobutyronitrile as initiator for 0.045% by weight (accounting for monomer), to sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com