Red light-emitting phosphor powder excited by UV and blue light LED

A phosphor and ultraviolet light technology, applied in the field of phosphors, can solve the problems of uneven distribution, large particle size, uneven luminescence of phosphors, etc., and achieve the effects of sufficient reaction, uniform mixing and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

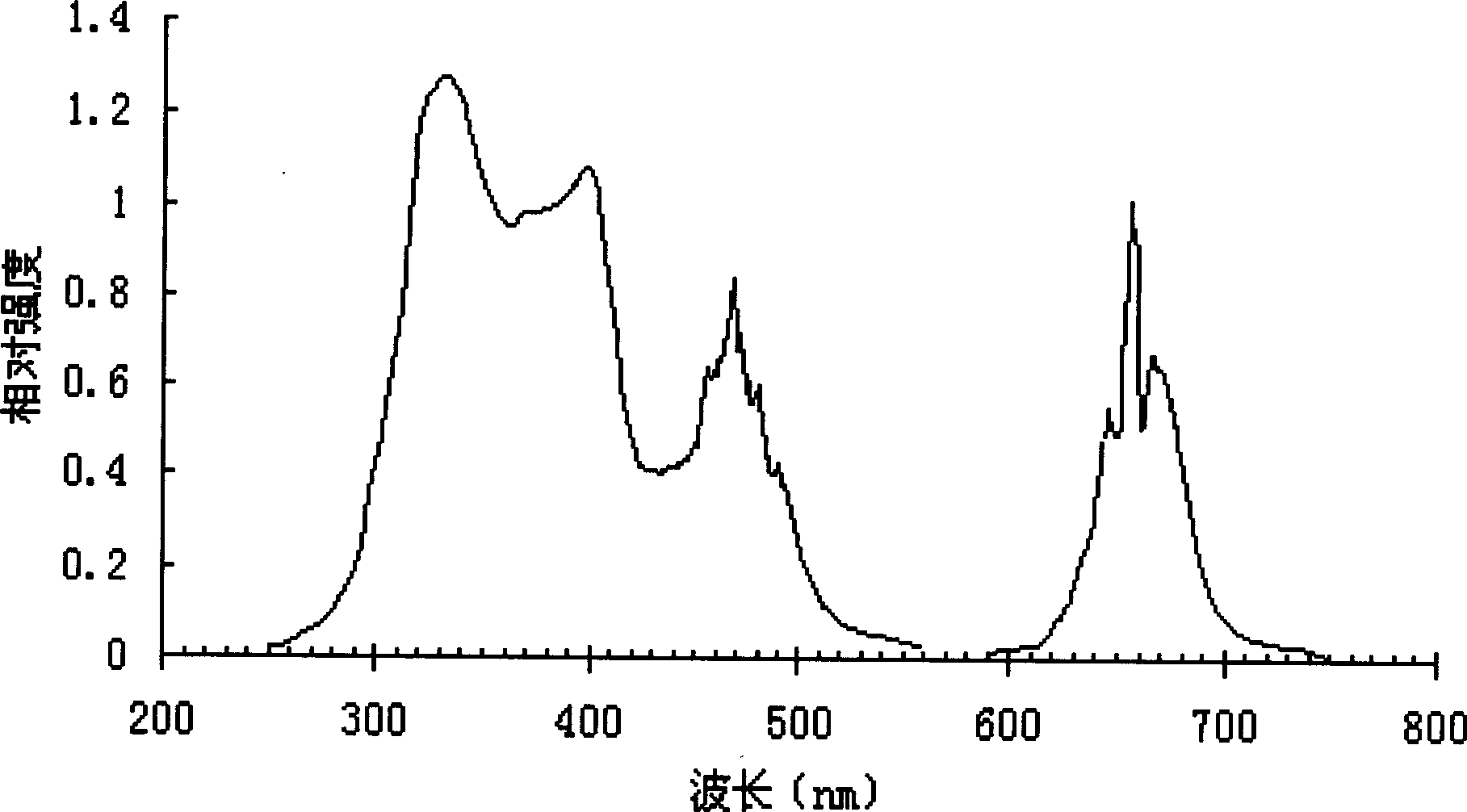

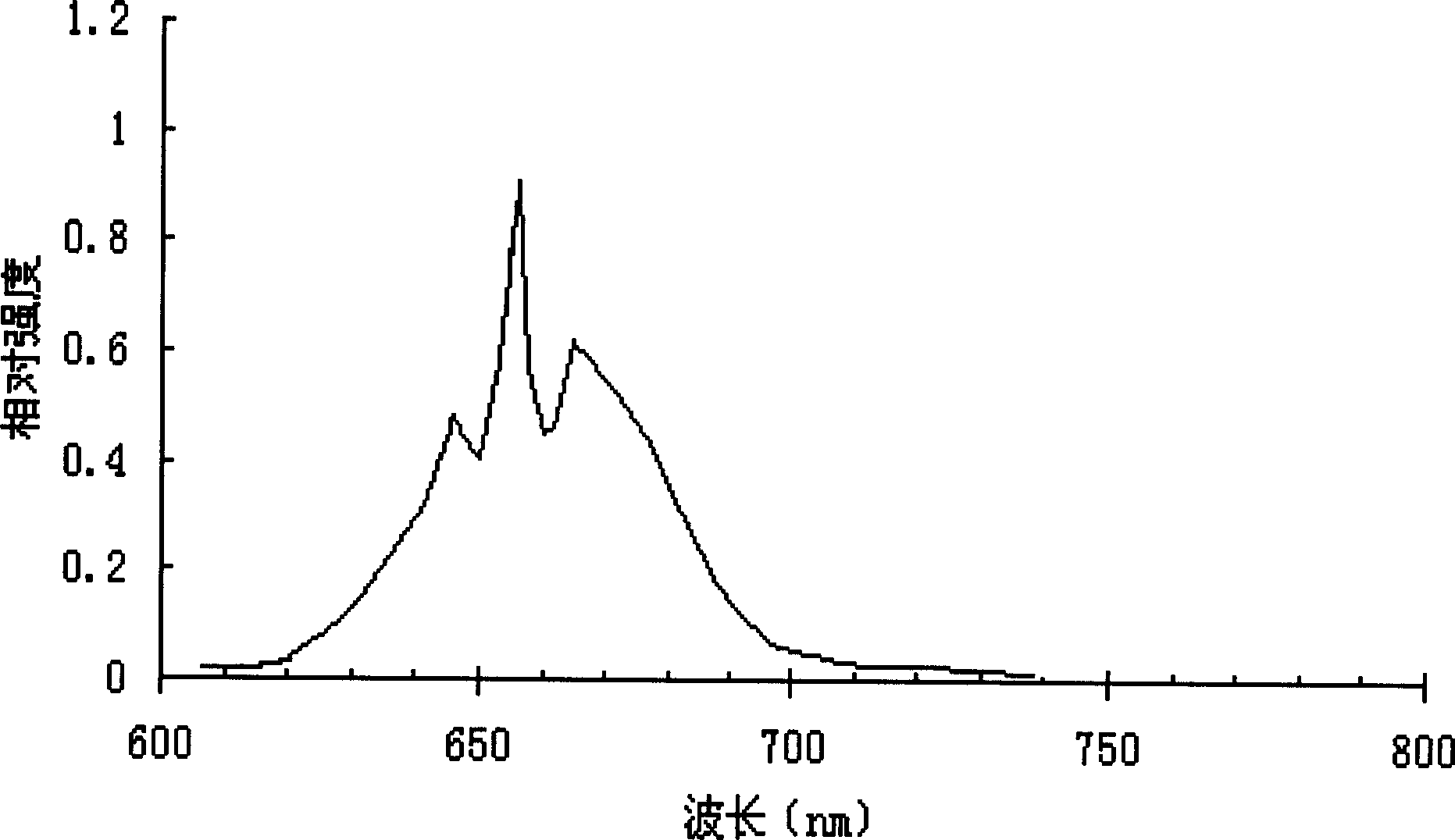

[0027] Embodiment one: (Sr0.6 Ba 0.1 Mg 0.3 )(Y 0.3 Al 0.4 Ga 0.3 ) 16 o 24 :Mn 0.005 T m 0.01 Eu 0.01

[0028] SrCO 3 8.856g Ga 2 o 3 44.98g Basic Magnesium 3.022g

[0029] BaCO 3 1.973g MnCO 3 0.115g

[0030] Y 2 o 3 54.19g Tm 2 o 3 0.193g

[0031] Al 2 o 3 32.64g Eu 2 o 3 0.176g

[0032] Flux 2.6g (CaF 2 , (NH 4 ) 2 HPO 4 , Li 2 CO 3 )

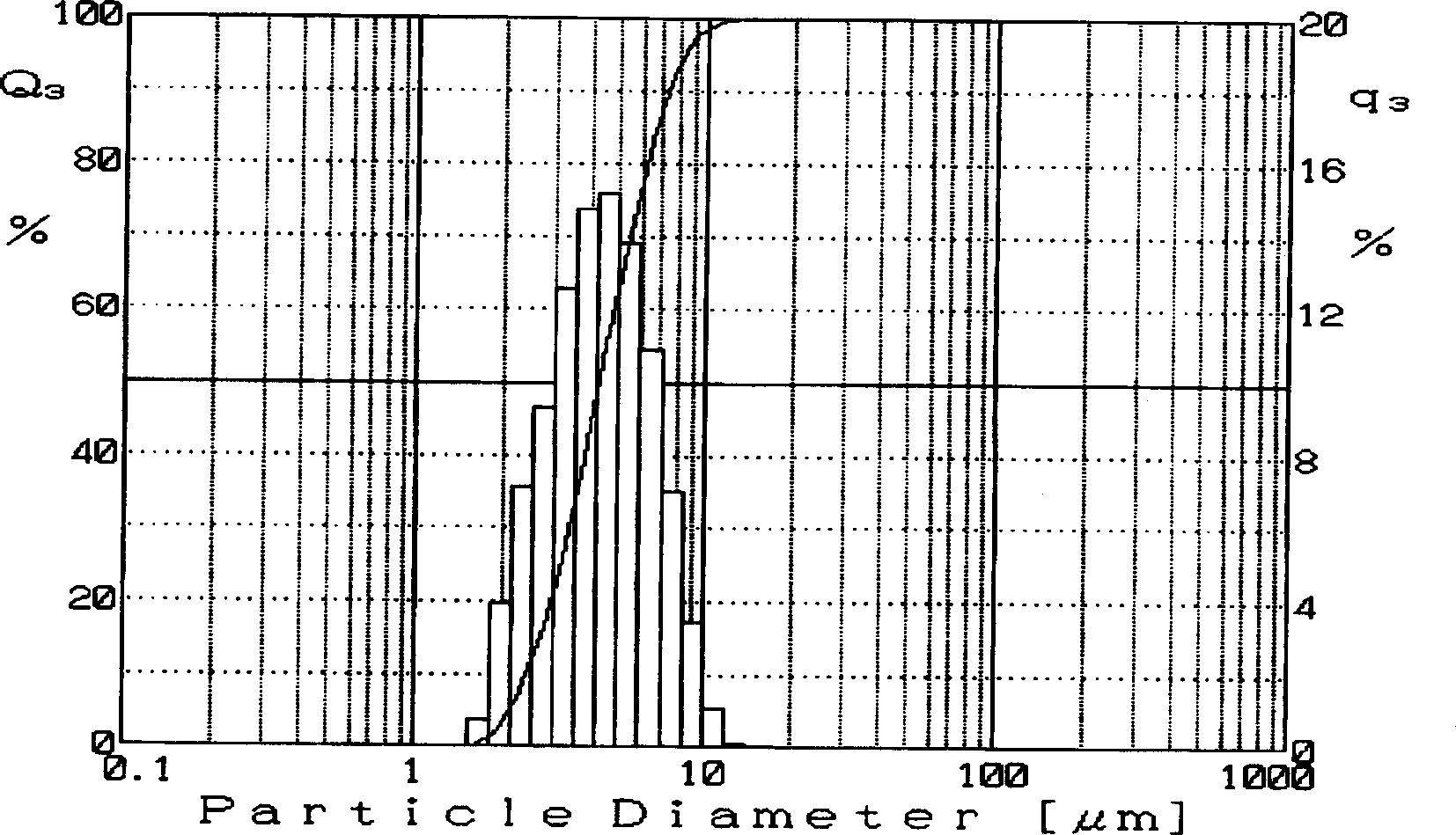

[0033] Put the above raw materials into a corundum ball mill jar and grind them evenly on a grinder, then put them into a 95% porcelain crucible, pre-fire at 1000°C for 8 hours in an oxygen atmosphere, cool and grind them, and then sinter at a high temperature of 1350°C for 10 hours. After crushing and sieving, the fluorescent powder was dispersed in an ethanol medium, classified by fluid sedimentation separation technology, and dried to obtain a material with a central particle diameter of 5.6 μm. Under the excitation of 300nm-500nm light (especially 400nm and 470nm), it presents an emission...

Embodiment 2

[0034] Embodiment two: (Sr 0.1 Ca 0.9 )(Gd 0.3 Al 0.7 ) 18 o 28 :Mn 0.03 Dy 0.02 SM 0.01

[0035] SrCO 3 1.471g MnSO 4 .H 2 O 0.507g

[0036] CaCO 3 9.000g Dy 2 o 3 0.373g

[0037] Gd 2 o 3 97.90g Sm 2 o 3 0.174g

[0038] Al 2 o 3 64.26g

[0039] Flux 2.4g (NH 4 F 1.0g MgF 2 0.5g H 3 BO 3 0.9g)

[0040] Put the above raw materials into a corundum ball mill pot and grind them evenly on a grinder, then put them into a 95% porcelain crucible, pre-fire at 1200°C for 6 hours in an oxygen atmosphere, cool and grind them, and then fire them at a high temperature of 1400°C for 6 hours. After crushing and sieving, the fluorescent powder was dispersed in an ethanol medium, classified by fluid sedimentation separation technology, and dried to obtain a material with a central particle diameter of 4.8 μm. Under the excitation of 300nm-500nm light (especially 400nm and 470nm), it presents an emission spectrum of 630nm-680nm. The peak w...

Embodiment 3

[0041] Embodiment three: Ca (Gd 0.1 Al 0.9 ) 14 o 22 :Mn 0.005 Eu 0.01 Ho 0.02

[0042] CaCO 3 10.00g MnCO 3 0.057g

[0043] Gd 2 o 3 25.38g Eu 2 o 3 0.176g

[0044] Al 2 o 3 64.26g Ho 2 o 3 0.378g

[0045] Flux 1.9g (NH 4 Cl 0.8g NaCl 0.4g K 3 PO 4 0.7g)

[0046] Put the above raw materials into a corundum ball mill jar and grind them evenly on a grinder, then put them into a 95% porcelain crucible, pre-fire at 900°C for 9 hours in an oxygen atmosphere, cool and grind them, and then fire at a high temperature of 1380°C for 6 hours. After pulverizing and sieving, the fluorescent powder was dispersed in an acetone medium, classified by fluid sedimentation separation technology, and dried to obtain a material with a central particle diameter of 4.0 μm. Under the excitation of 300nm-500nm light (especially 400nm and 470nm), it presents an emission spectrum of 630nm-680nm. The peak wavelength is 647.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central particle size | aaaaa | aaaaa |

| Central particle size | aaaaa | aaaaa |

| Central particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com