Display method of converting infrared laser path into visible light

An infrared laser and display method technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor measurement accuracy and troublesome operation, and achieve accurate positioning, high luminous efficiency, and high laser damage resistance threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

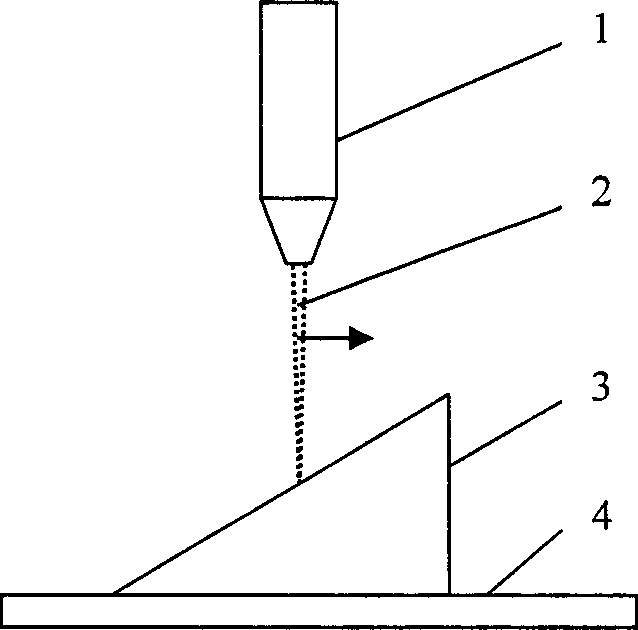

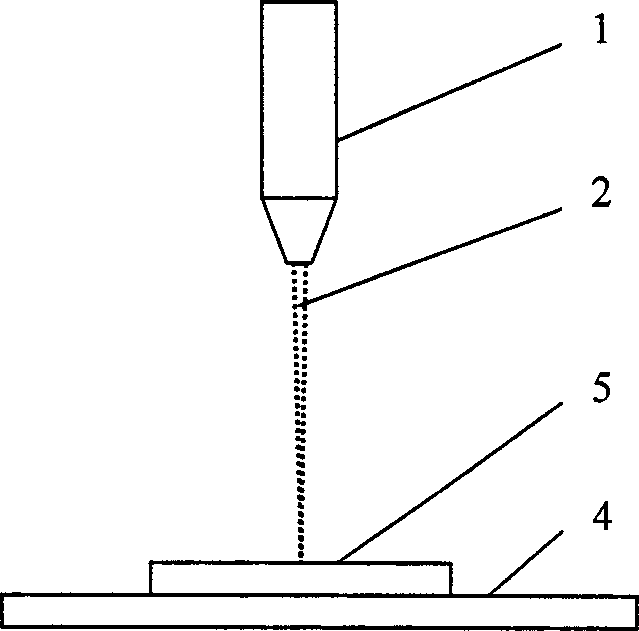

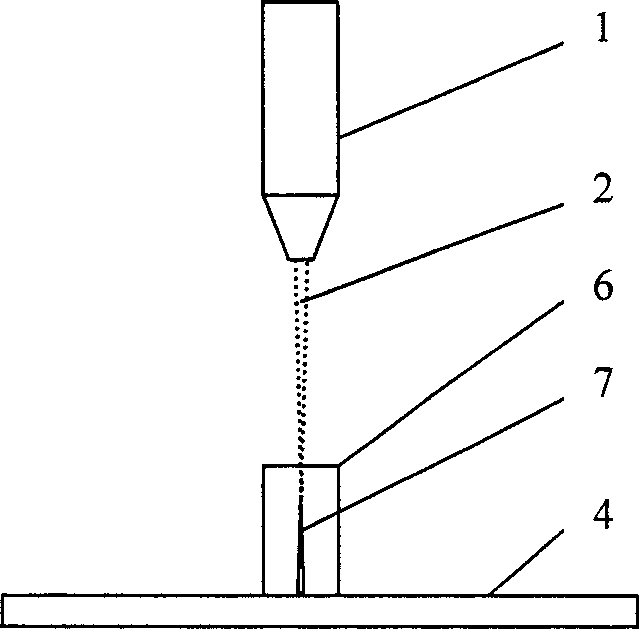

Image

Examples

Embodiment Construction

[0034] 1.Tm 3+ :ZnWO 4 Crystal preparation

[0035] Growth of Tm in resistance furnace heated by SiC rods under atmospheric atmosphere by pulling method 3+ :ZnWO 4 crystals. First ZnO, WO 3 and Tm 2 o 3 Powder is weighed by 1: 1 molar ratio, Tm in the present invention 3+ The ion doping concentration is 0.1 mol% to 2.0 mol%. Mix the raw materials evenly, put them into a platinum crucible, and the purity of the raw materials is 4N. Put the crucible into a resistance furnace, raise the temperature to 1205°C, place the seed crystal after the material is completely melted, and grow Tm through the processes of necking, shoulder expansion, equal diameter, and finishing. 3+ :ZnWO 4 crystals. The process conditions are: axial temperature gradient ΔG≥30°C / cm, crystal rotation speed 15-40r.p.m., and pulling speed≤4mm / h.

[0036] 2. Subsequent processing of crystals

[0037] Put the crystal into an annealing furnace, heat it to 1100°C, keep it warm for 3 hours, and then drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com