Prepn process of 1-fluoronaphthalene

A technology of fluoronaphthalene and naphthylamine, which is applied in the field of preparation of 1-fluoronaphthalene, can solve the problems of difficult industrial production, difficult realization of fluorinating agent equipment, and many by-products at reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

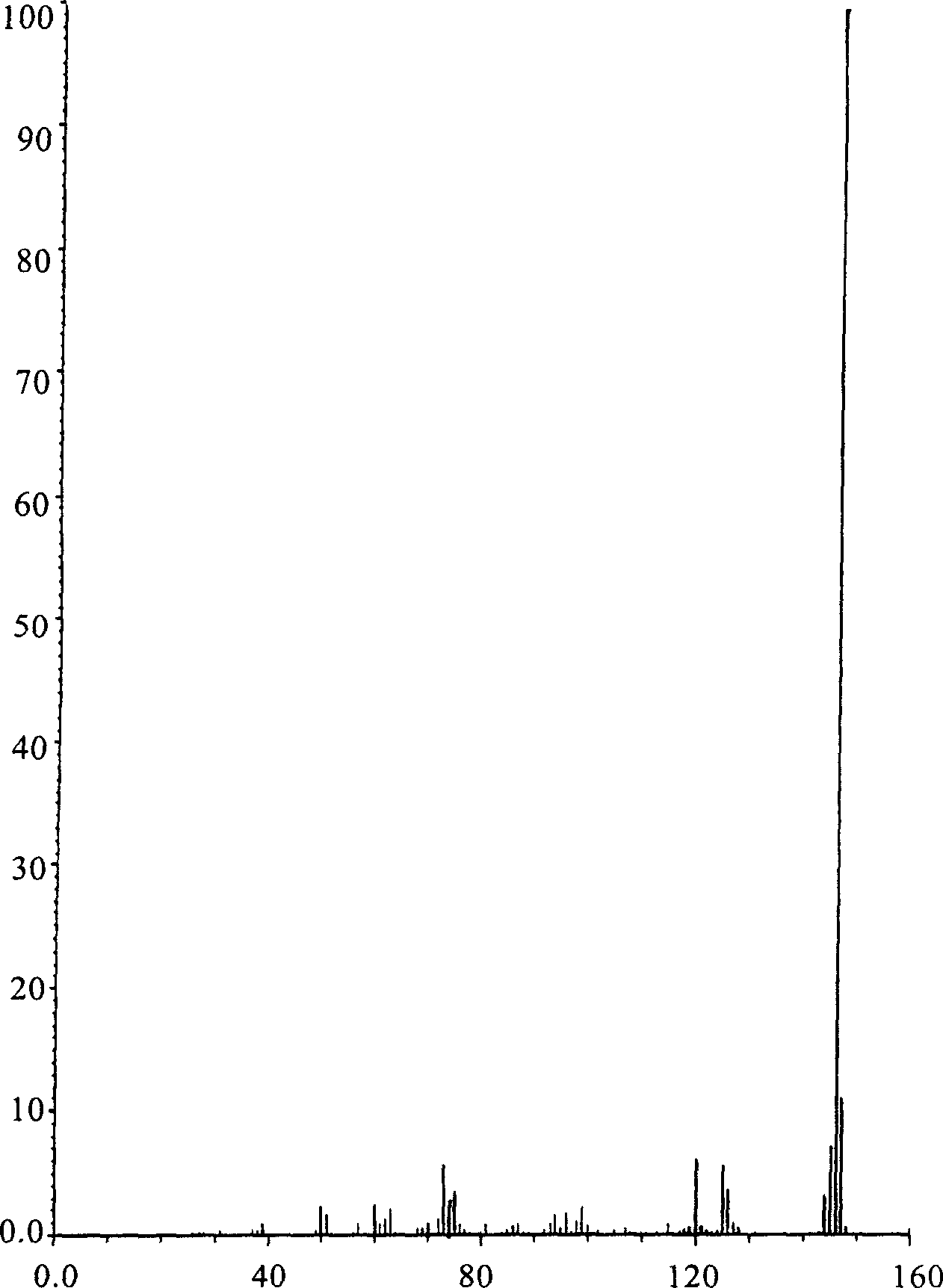

Image

Examples

preparation example Construction

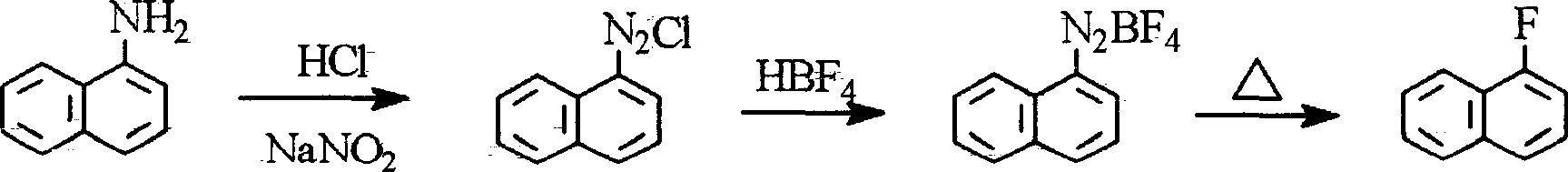

[0017] The preparation method of 1-fluoronaphthalene of the present invention uses 1-naphthylamine as a raw material, undergoes diazotization to form diazonium fluoroborate or diazonium fluorophosphate, and then conducts thermal decomposition to form 1-fluoronaphthalene product.

[0018] Specifically, the preparation method of 1-fluoronaphthalene comprises the following steps:

[0019] (1) 1-naphthylamine is reacted with nitrous acid, nitrite or nitrite in an acidic medium to obtain a diazonium salt;

[0020] (2) reacting the diazonium salt obtained in step (1) with fluoroboric acid or its salt or fluorophosphoric acid or its salt to obtain diazonium fluoroborate or diazonium fluorophosphate;

[0021] (3) Thermally decomposing the diazonium fluoroborate or diazonium fluorophosphate obtained in step (2) to obtain 1-fluoronaphthalene.

[0022] In step (1), the acidic medium can be any medium suitable for providing an acidic environment for the diazotization reaction, including ...

Embodiment 1

[0035] Add 143 grams (equivalent to 1 mole) of 1-naphthylamine and 400ml hydrochloric acid solution into a 2000ml four-neck flask, keep the temperature at 50-60°C and stir for about half an hour, then cool the temperature of the reaction solution to -3°C, add dropwise Add 250ml of 40% sodium nitrite aqueous solution (equivalent to 1.1 mole of sodium nitrite), add dropwise for about 2 hours, and keep warm for about half an hour. Then, 308ml of 40% fluoroboric acid aqueous solution (equivalent to 1.4 moles of fluoroboric acid) was added dropwise, and fine solids were formed immediately, and the dropwise addition lasted for about half an hour. After stirring for 1 hour, suction filtration, washing, and drying gave diazonium fluoroboron Salt solid 222.8 grams.

[0036] Heat a 1000ml four-necked bottle with the temperature controlled at 70-75°C, put in the solid diazonium fluoroborate obtained above in batches, and make it thermally decompose. After the decomposition is completed, ...

Embodiment 2

[0038] Add 143 grams (equivalent to 1 mole) of 1-naphthylamine and 450ml of sulfuric acid solution into a 2000ml four-necked bottle, keep the temperature at 60-70°C and stir for about half an hour, then cool the temperature of the reaction solution to 5°C, and add 40 % sodium nitrite aqueous solution 680ml (equivalent to 3.0 moles of sodium nitrite), continue to add dropwise for about 2 hours, and keep warm for about half an hour. Then, 270ml of 40% sodium fluoroborate aqueous solution (equivalent to 1.2 moles of sodium fluoroborate) was added dropwise, and fine solids were formed immediately, and the dropwise addition continued for about half an hour. After stirring for 1 hour, suction filtered, washed, and dried to obtain diazo Fluoroborate solid 232 grams.

[0039]Heat a 1000ml four-neck bottle, control the temperature at 140-150°C, put in the solid diazonium fluoroborate obtained above in batches, and make it thermally decompose. After the decomposition is completed, recti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com