Direct titanium alloy producing process with titanium containing mineral

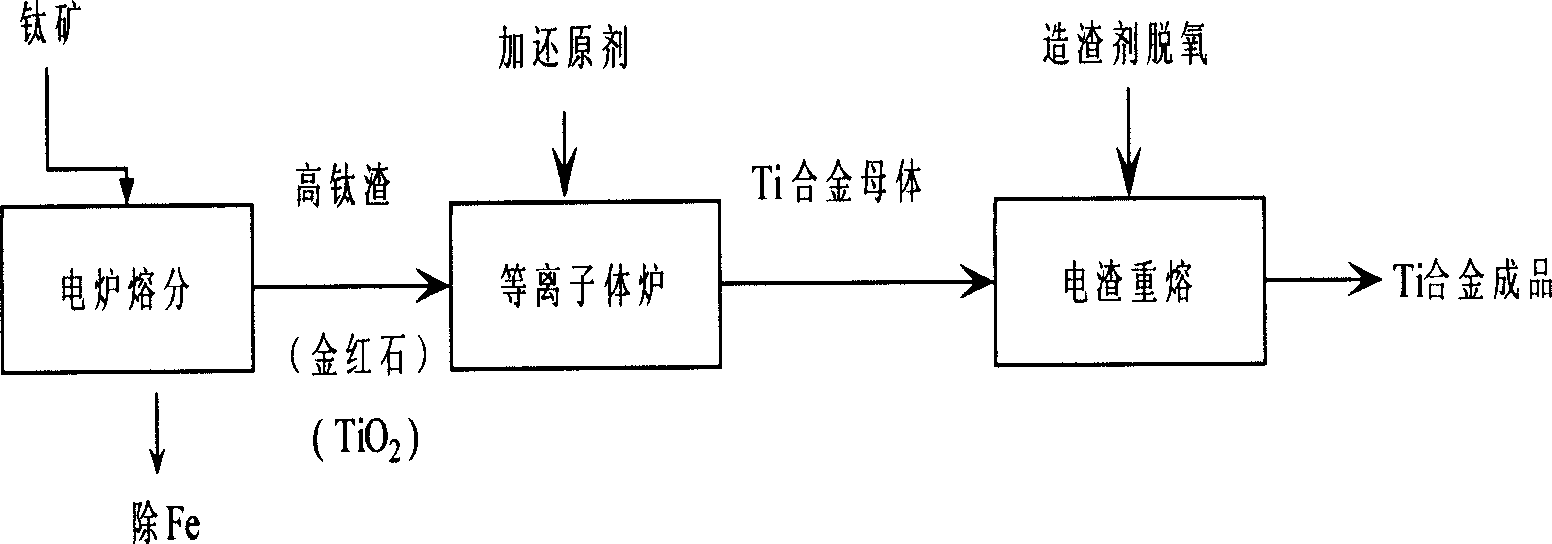

A technology of titanium minerals and titanium alloys, applied in the field of metal titanium metallurgy, can solve the problems of complex titanium metal process, low productivity, high processing and production costs, and achieve the effects of shortening the process cycle, avoiding pollution, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

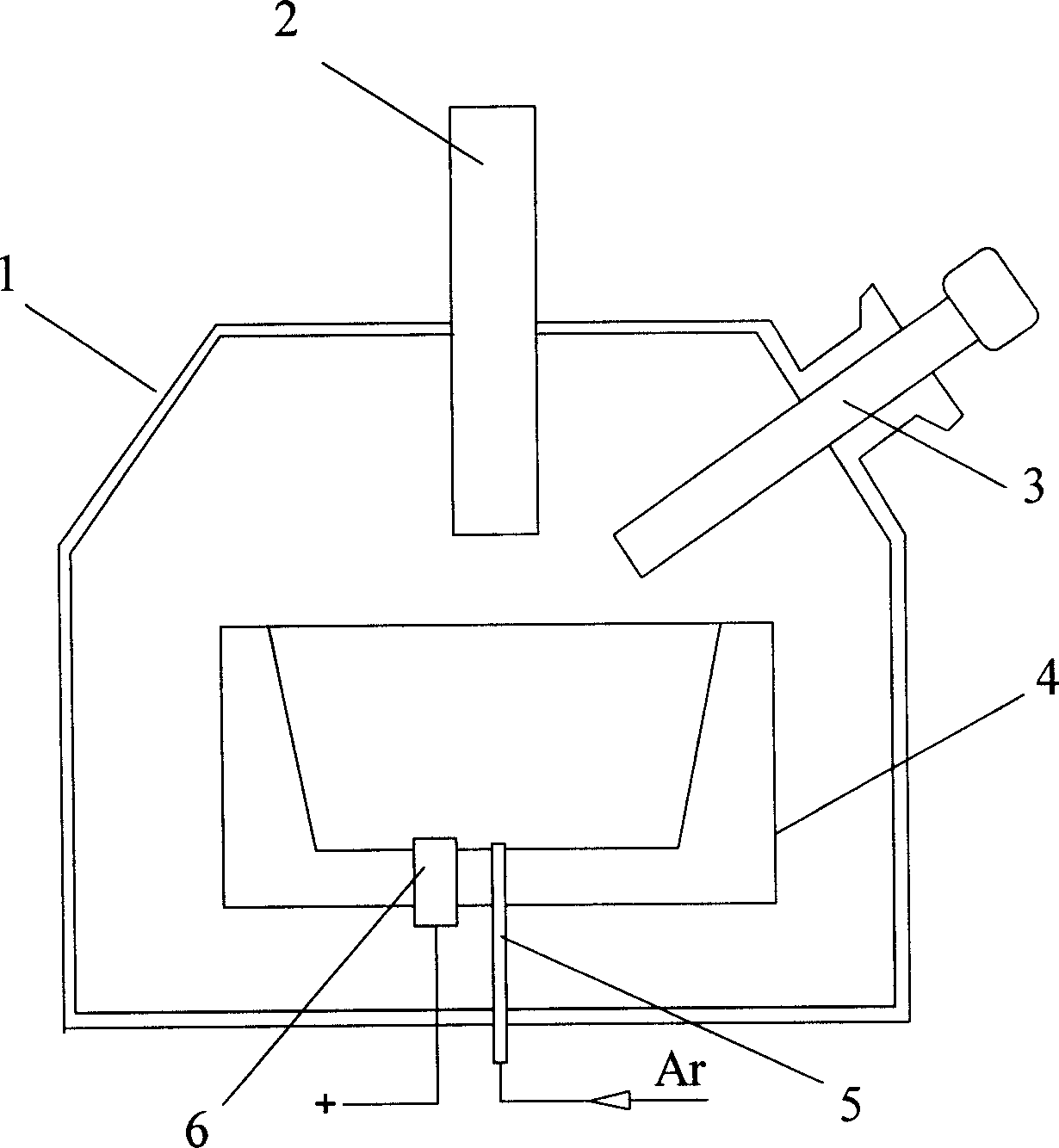

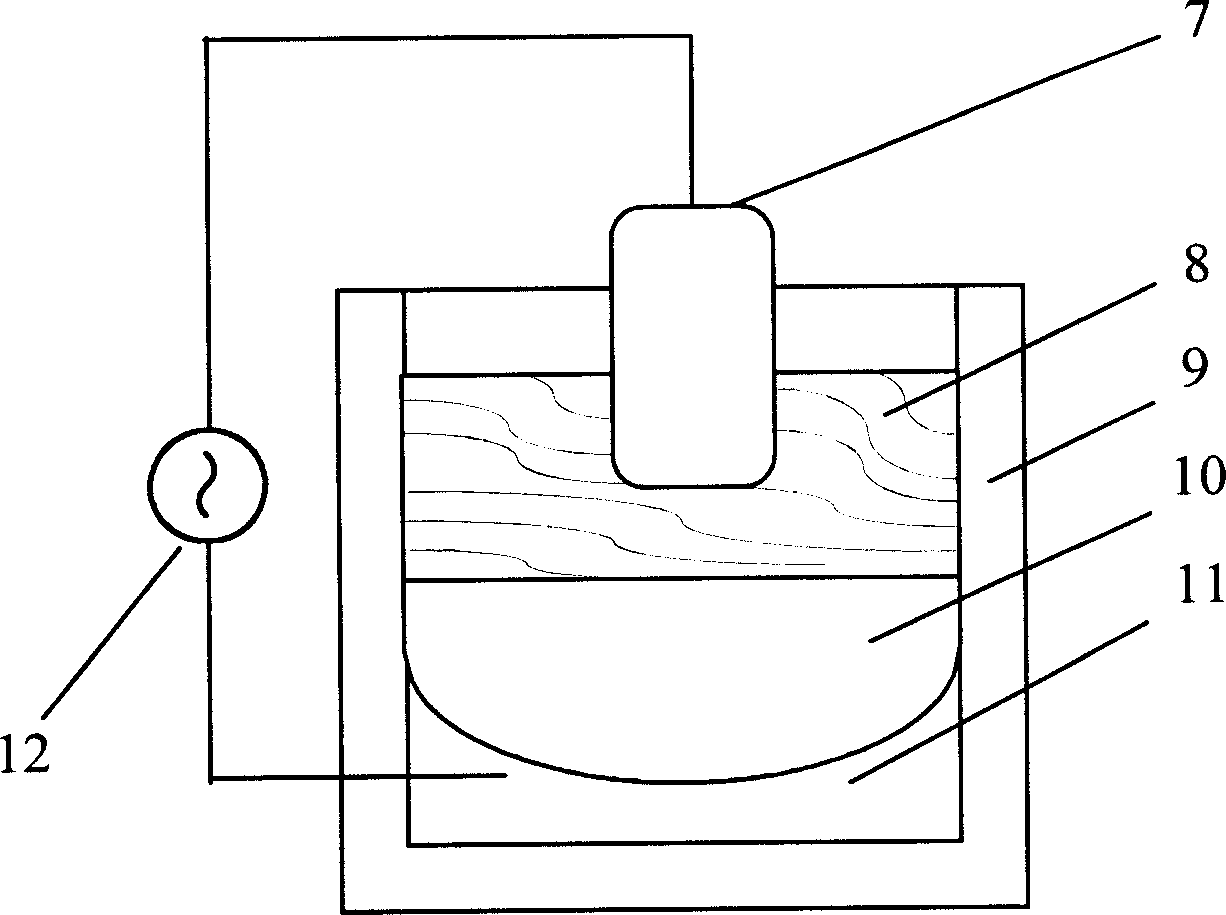

Method used

Image

Examples

Embodiment Construction

[0019] 1. Production of titanium-aluminum alloy with Guangxi ilmenite placer as raw material

[0020] Guangxi ilmenite placer, its main chemical composition is TiO 2 (50.94%), FeO (28.61%), Fe 2 o 3 (16.68%), in addition to containing a small amount of SiO 2 , Al 2 o 3 , P 2 o 5 , MgO, MnO, CaO, etc. Firstly, in a submerged-thermal electric arc furnace, at a high temperature of 1600-1800°C, petroleum coke is used as a reducing agent for reduction, and the reaction product Fe is separated to obtain high-titanium slag. Fully mix high-titanium slag, Al powder and CaO, and react in a transferred arc plasma heating furnace to generate Ti and Al 2 o 3 , separation of CaO-Al 2 o 3 slag to obtain titanium aluminum alloy. Then the electroslag remelting method is used to remove the impurity elements in the titanium-aluminum alloy to obtain the finished titanium alloy.

[0021] 2. Using rutile ore to produce titanium-aluminum alloy

[0022] The main chemical composition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com