Extruded-puffed potato full-powder food and its processing method

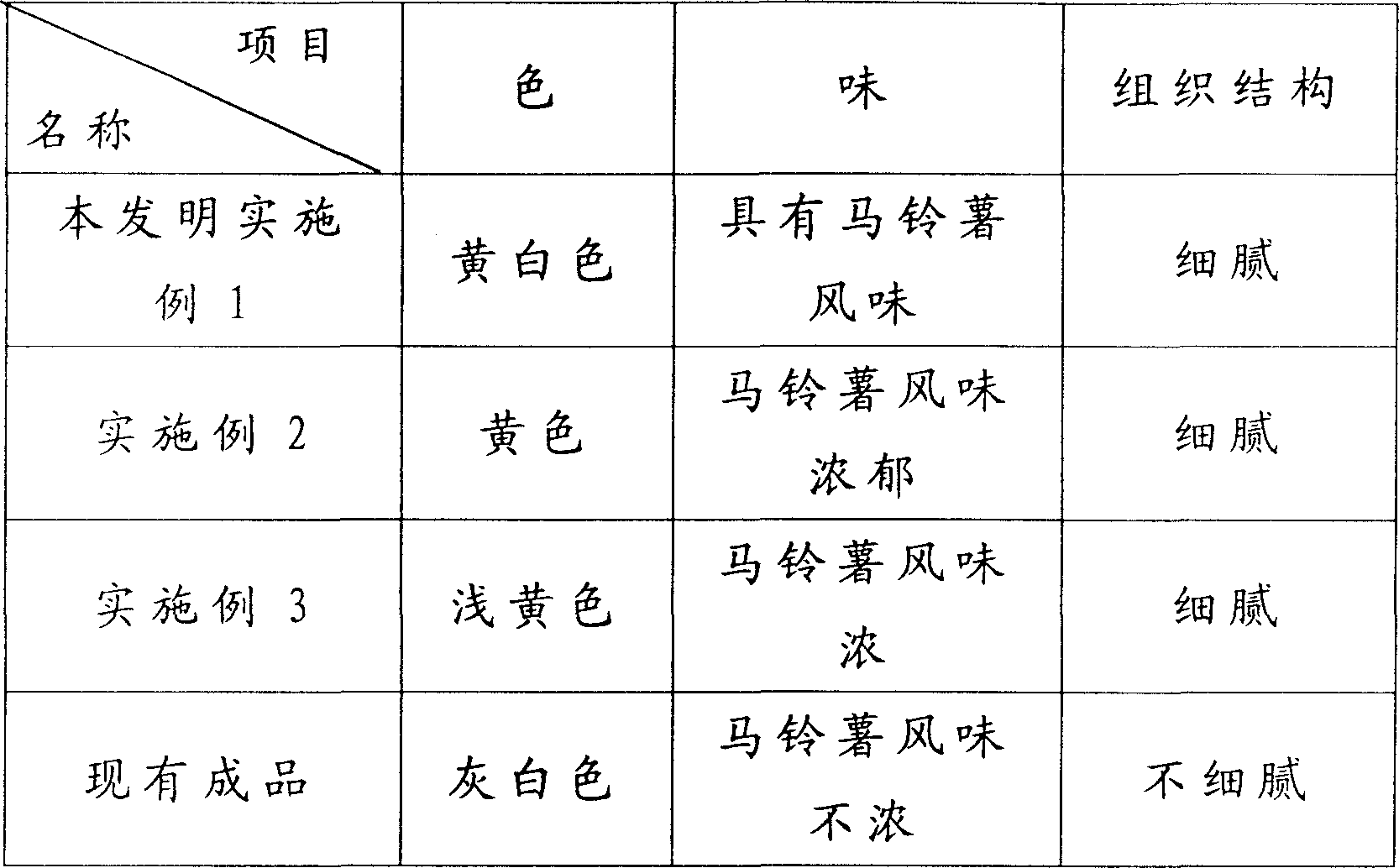

A technology of potato powder and extrusion puffing, which is applied in food preparation, food science, application, etc. It can solve the problems of unrefined product structure, difficult product quality control, and increased difficulty in product color protection, so as to achieve uniform product structure , Product quality is easy to control, and the effect of strong potato flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, get potato whole powder 395kg, rice flour 280kg, corn flour 120kg, potato starch 120kg, white granulated sugar 20kg, whole milk powder 10kg, oat dietary fiber 30kg, calcium carbonate 3kg, soybean lecithin 2kg and mix, add palm Oil 20kg, continue to stir, then add 45kg of water, and stir again; the above mixture is sent to a twin-screw extruder for puffing, and the extruder operating parameters are: the cavity temperature is controlled as: T 1 50℃, T 2 110℃, T 3 160℃, T 4 180℃, the feeding speed is 100kg / h, and the screw speed is 700rpm; after extrusion, it is cut with a high-speed cutter, and the cutter speed is 750rpm; it is dried and baked into a billet, and the baking temperature is 180℃ and the time is After 20 minutes, the formed billet was cooled to 70°C; the billet was sprayed with 60°C palm oil and onion, pepper, salt, and salt seasoning powder, and the finished product was finished after packaging.

Embodiment 2

[0027] Embodiment 2, get potato whole powder 675kg, rice flour 100kg, corn flour 60kg, corn starch 60kg, white granulated sugar 40kg, whole milk powder 10kg, wheat dietary fiber 20kg, calcium carbonate 2.5kg, soybean lecithin 2.5kg and mix and stir, Add 30kg of shortening, continue stirring, add 60kg of water, and stir again; the above mixture is sent to a twin-screw extruder for puffing, and the extruder operating parameters are: the cavity temperature is controlled as: T 1 30℃, T 2 100℃, T 3 150℃, T 4 170℃, the feeding speed is 80kg / h, and the screw speed is 700rpm; after extrusion, it is cut with a high-speed cutter, and the cutter speed is 750rpm; and then dried and baked into a billet, the baking temperature is 160℃, and the time is After 30 minutes, the formed billet was cooled to 78°C; 80°C palm oil and spicy beef flavor seasoning powder were sprayed on the billet, and the finished product was finished after packaging.

[0028] The whole potato powder is boiled for 1...

Embodiment 3

[0029] Embodiment 3, get potato whole powder 500kg, rice flour 180kg, corn flour 90kg, potato starch 90kg, white granulated sugar 60kg, whole milk powder 15kg, wheat dietary fiber 30kg, calcium carbonate 3.5kg, soybean lecithin 1.5kg and mix, Add 30kg of palm oil, continue to stir, then add 50kg of water, and stir again; the above mixture is sent to a twin-screw extruder for puffing, and the extruder operating parameters are: the cavity temperature is controlled as: T 1 50℃, T 2 120℃, T 3 170℃, T 4180°C, the feeding speed is 120kg / h, and the screw speed is 800rpm; after extrusion, it is cut with a high-speed cutter, and the cutter speed is 800rpm; and then dried and baked into a billet, the baking temperature is 180°C, and the time is After 20 minutes, the formed blank was cooled to 65°C; palm oil and tomato-flavored seasoning powder was sprayed on the blank at 70°C, and the finished product was finished after packaging.

[0030] The whole potato powder is boiled in a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com