Method for apparatus for treating ammonia-containing gas

A gas and pretreatment technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as water quality deterioration, odor and environmental pollution, and achieve the effect of increasing NOX by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

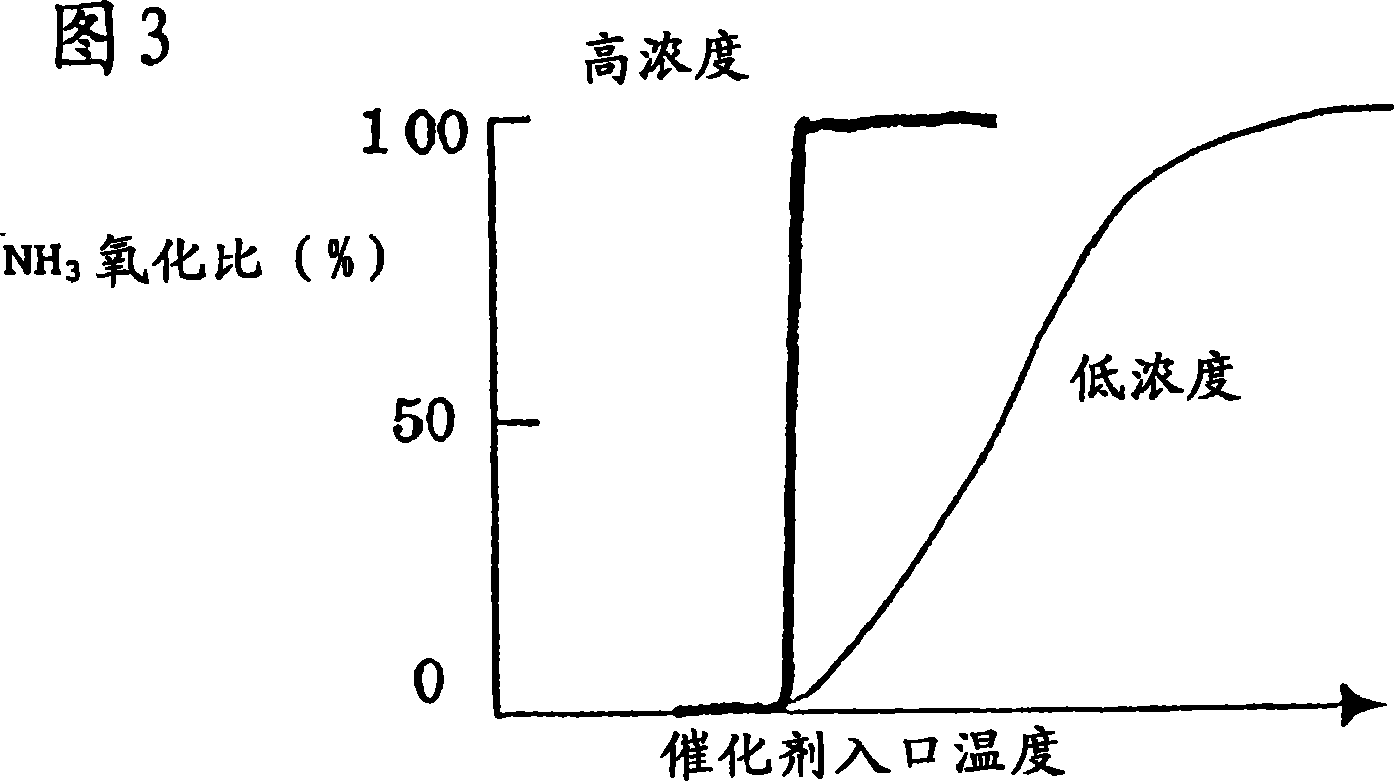

Problems solved by technology

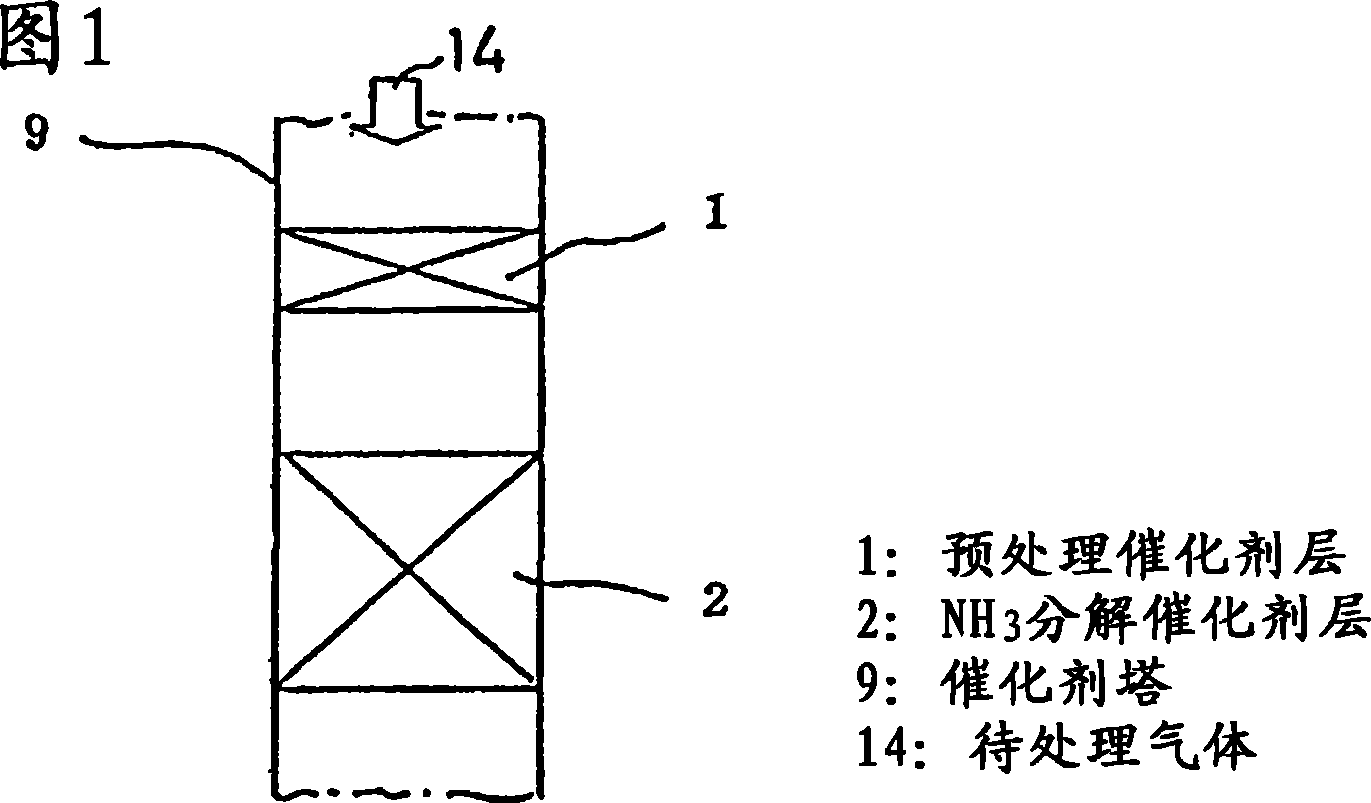

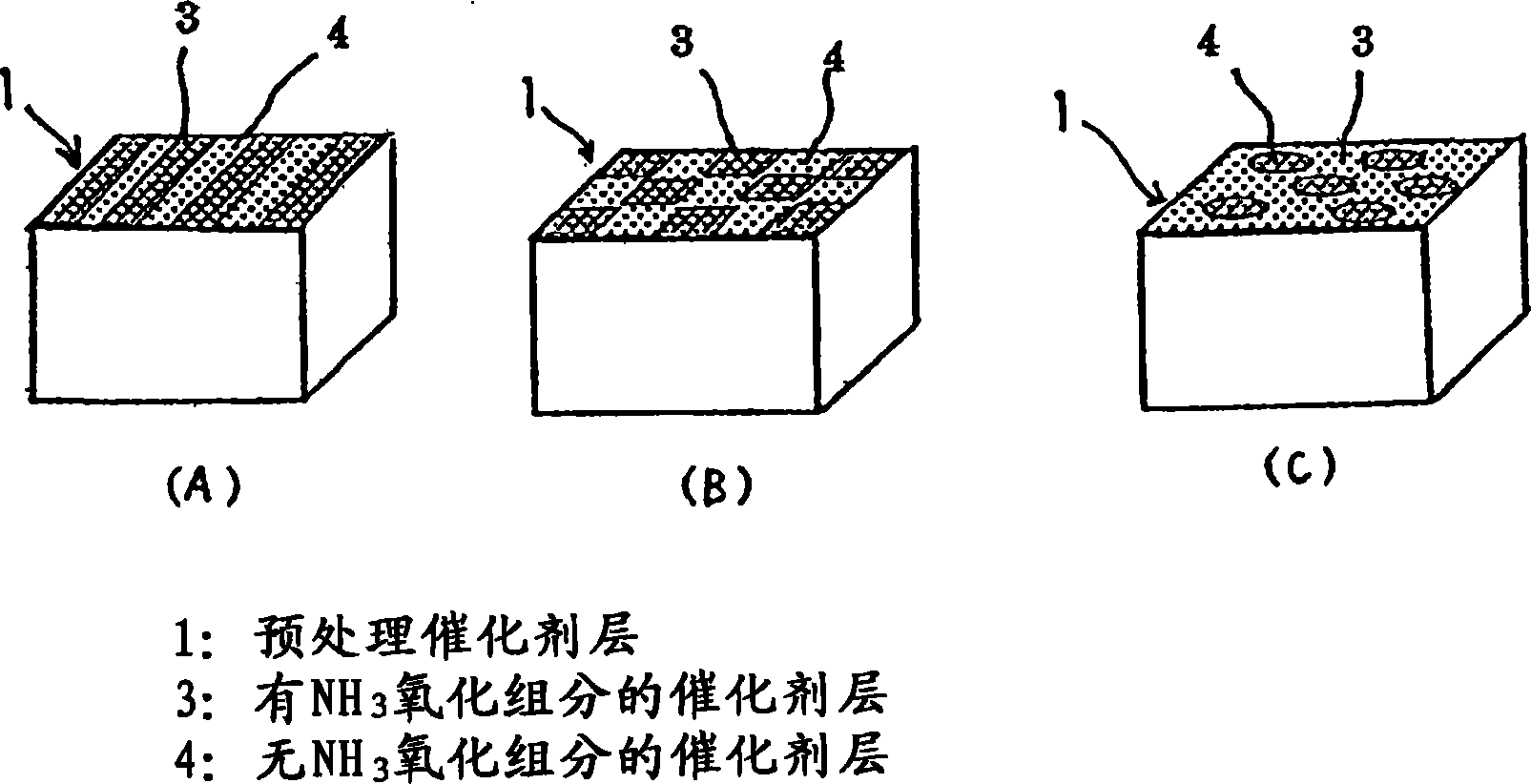

Method used

Image

Examples

example 1

[0071] To 50 grams of hydrogen-substituted type (hydrogen-substituted type) Mordenite powder (HSZ-650 produced by Tosoh Company, SiO 2 / Al 2 o 3 =23), add the specified amount of chloroplatinic acid (HPtCl 6 .6H 2 O) in an aqueous solution so that the weight ratio of Pt was 0.5%, the mixture was dehydrated and dried, and the resulting product was calcined at 550° C. for 2 hours, so as to obtain a Pt-Mordenite catalyst. The obtained catalyst was slurried with silica gel and water, and a commercially available corrugated honeycomb support made of silica-alumina fibers (manufactured by NICHIAS Corporation, having a square of 150 and a length of 20 Honeycle 3722), and then, a Pt-Mordenite catalyst with a honeycomb structure was obtained after air drying for 2 hours, drying at 120° C. for 2 hours, and calcination at 500° C. for 2 hours. The Pt loading capacity of the catalyst is 0.75 g / L. The catalyst was cut to a width of 25 mm in order to obtain NH containing 3 25 x 150-L20...

example 2

[0076] The pretreatment catalyst layer is obtained in this way, which is the same as that described in Example 1 above, except that the preparation method of the pretreatment catalyst layer in Example 1 is changed, as described below.

example 1

[0077] The corrugated honeycomb material (150 square-L20) made of the silica-alumina fiber used in Example 1 uses 30% TiO 2 Sol (manufactured by Ishihara Sangyo Kabusiki Kaisha Co., Ltd.) was impregnated, after which the liquid was discharged by blowing air, and dried at 150°C. The obtained material was cut into pieces each having a width of 30, and then the three pieces were impregnated with dinitrodiamine platinum solution (Pt concentration: 1.33 g / L), dried again, and then these pieces were combined with the remaining two pieces. Calcined together at 600°C. The two types of obtained materials were laminated alternately with each other in order to obtain pretreatment catalyst layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com