Production of copper-alloy bearing retainer by die casting method

A technology of bearing cage and copper alloy, which is applied in the field of mechanical processing, can solve problems such as difficult die-casting of copper alloy bearing cages, and achieve the effects of low cost, good corrosion resistance, and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

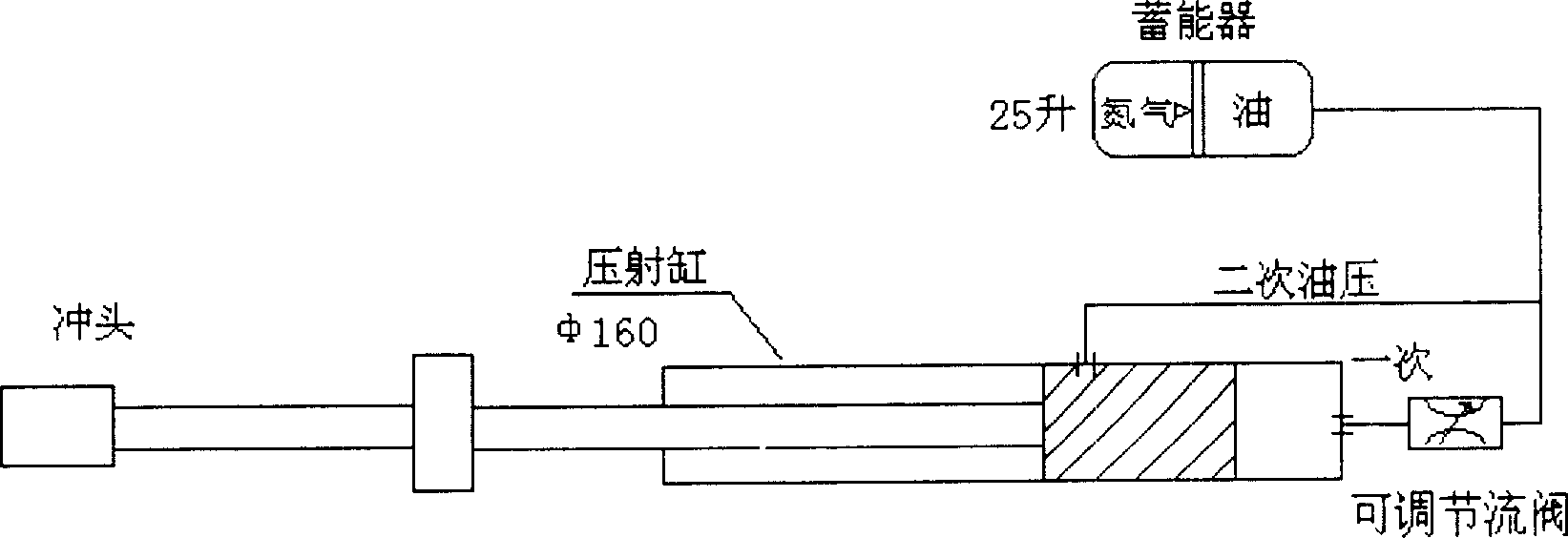

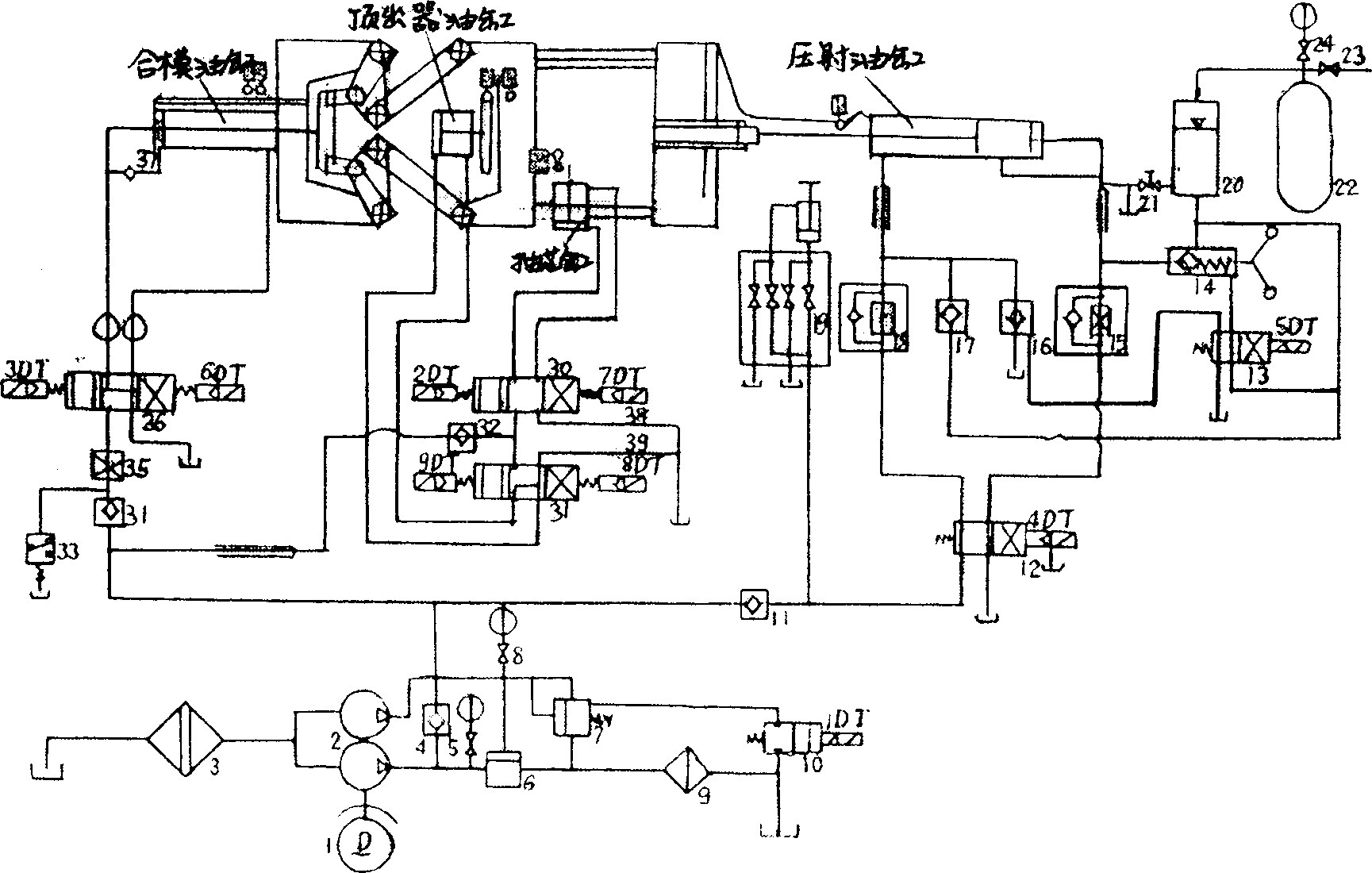

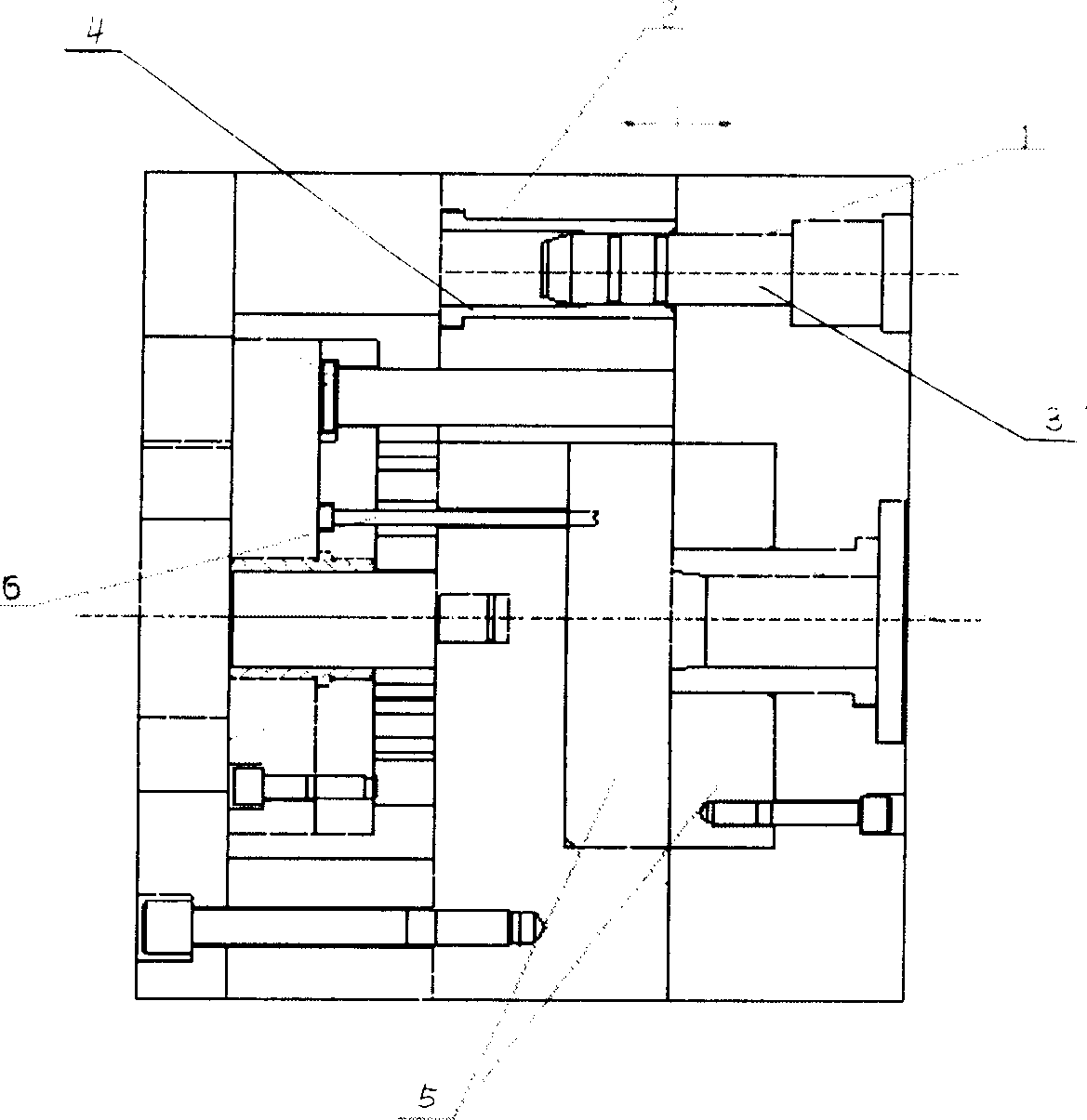

[0012] Embodiment 1: First, the three-stage injection of the die-casting machine, that is, the three-stage pressurization (compacting), is moved forward to the second stage, which is completed at the same time as the second stage, to shorten the injection time, and prevent the alloy from being unable to pressurize after solidification; copper The die-casting brass used for the alloy bearing cage and retaining ring is YT40-1, and its chemical composition is mainly: Cu: 58-63%, Pd: 0.5-1.5%, Al: 0.2-0.5%, and the rest is Zn. Its liquidus temperature is 1083°C, solidus temperature is 1065°C, and its solidification time is very short, about 0.1 second; the flow rate of the hydraulic pump is changed into two large pumps of 80 to 150 liters, and the supply is divided; The specific steps are: after the electromagnet two-position four-way electro-hydraulic valve 4DT is connected, the high-pressure oil coming out of the accumulator is blocked by a special thick piston, so the high-press...

Embodiment 2

[0027] Embodiment 2: First, the three-stage injection of the die-casting machine, that is, the three-stage pressurization (compaction), is moved forward to the second stage, and completed at the same time as the second stage, shortening the injection time, preventing the alloy from being unable to pressurize after solidification; copper The die-casting brass used for the alloy bearing cage and retaining ring is YT40-1, and its chemical composition is mainly: Cu: 58-63%, Pd: 0.5-1.5%, Al: 0.2-0.5%, and the rest is Zn. Its liquidus temperature is 1083°C, solidus line temperature is 1065°C, and the solidification time is very short, about 0.1 second; the flow rate of the hydraulic pump is changed into two large pumps of 80-150 liters, and the supply is divided; The specific steps are: after the electromagnet two-position four-way electro-hydraulic valve 4DT is connected, the high-pressure oil from the accumulator is blocked by a special thick piston, so the high-pressure oil canno...

Embodiment 3

[0030] Embodiment 3: First, the three-stage injection of the die-casting machine, that is, the three-stage pressurization (compacting), is moved forward to the second stage, which is completed at the same time as the second stage, shortening the injection time, and preventing the alloy from being unable to pressurize after solidification; copper The die-casting brass used for the alloy bearing cage and retaining ring is YT40-1, and its chemical composition is mainly: Cu: 58-63%, Pd: 0.5-1.5%, Al: 0.2-0.5%, and the rest is Zn. Its liquidus temperature is 1083°C, solidus temperature is 1065°C, and its solidification time is very short, about 0.1 second; the flow rate of the hydraulic pump is changed into two large pumps of 80 to 150 liters, and the supply is divided; The specific steps are: after the electromagnet two-position four-way electro-hydraulic valve 4DT is connected, the high-pressure oil coming out of the accumulator is blocked by a special thick piston, so the high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com