Multi-lightbeam laser synthetic homogenizer

A technology of laser synthesis and multi-beam, which is applied in the coupling of optical waveguides and other directions, can solve the problems of large loss of light energy and difficulty in making bifurcated optical fibers, and achieves small loss of light energy, reduced laser polarization and coherence, and no The effect of interference noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

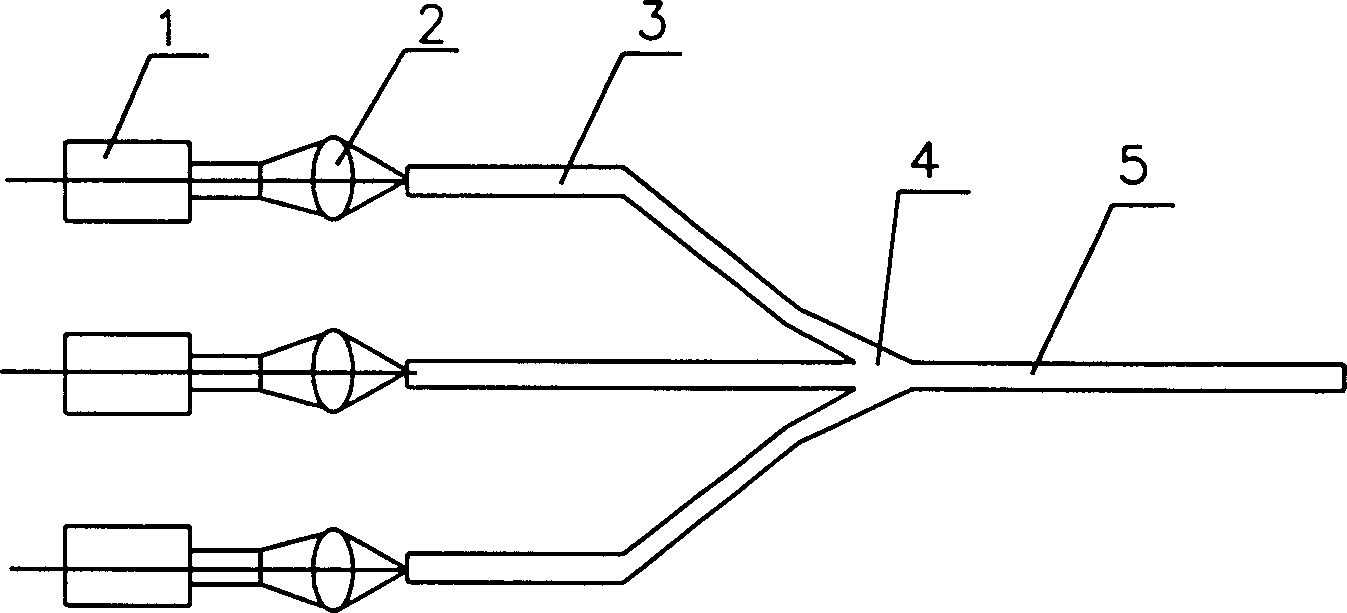

Method used

Image

Examples

Embodiment Construction

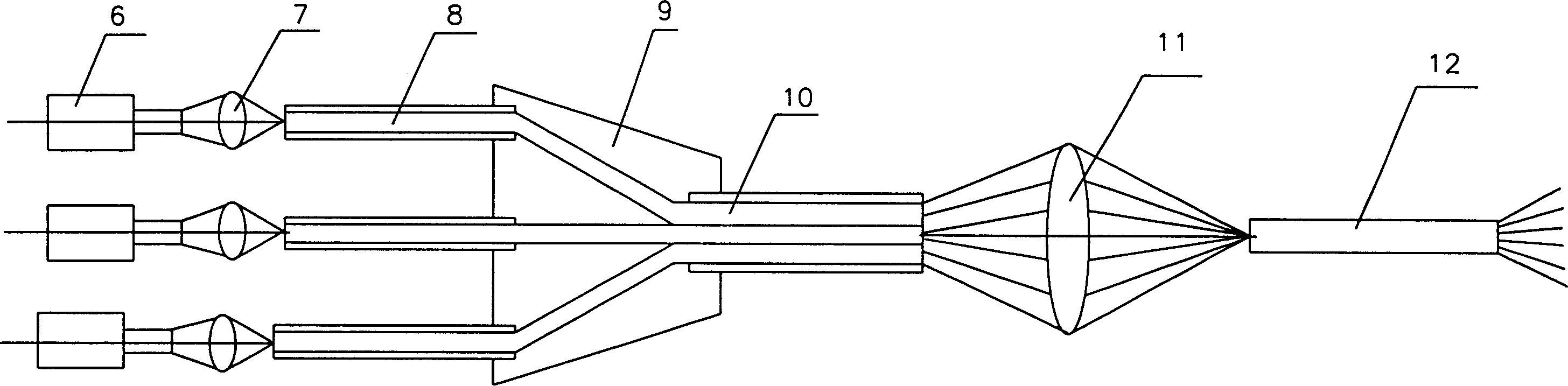

[0011] The optical fiber adopts a quartz optical fiber with a core diameter of 0.4mm, the synthetic beam condenser 11 adopts a lens with a diameter of φ15mm and a focal length F=16mm, and the homogenizing rod 12 adopts a K9 glass rod with a square cylinder of 6mm×6mm×60mm.

[0012] In the laser display, three optical fibers can be used to make the discrete-end optical fiber 8 and the bundled optical fiber 10, and the three cores in the bundled optical fiber 10 are arranged closely in the shape of a finished font. Red, green, and blue lasers are respectively input at the input ends of the three discrete-end optical fibers 8 , and the combined color light is output in parallel from the output end of the bundled optical fiber 10 . Because the three fiber cores in the bundled optical fiber 10 are arranged closely in the shape of a finished product, and the diameters of the three optical fibers are smaller (each 0.4mm), so the light emitted from these three fiber cores basically rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com