2 mu m bonded monoblock and non-planar longitudinal-mode laser

A single longitudinal mode laser and laser technology, applied in the laser field, can solve problems such as limiting the efficient operation of lasers, complex design of non-planar monolithic crystals, and certain difficulties in processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

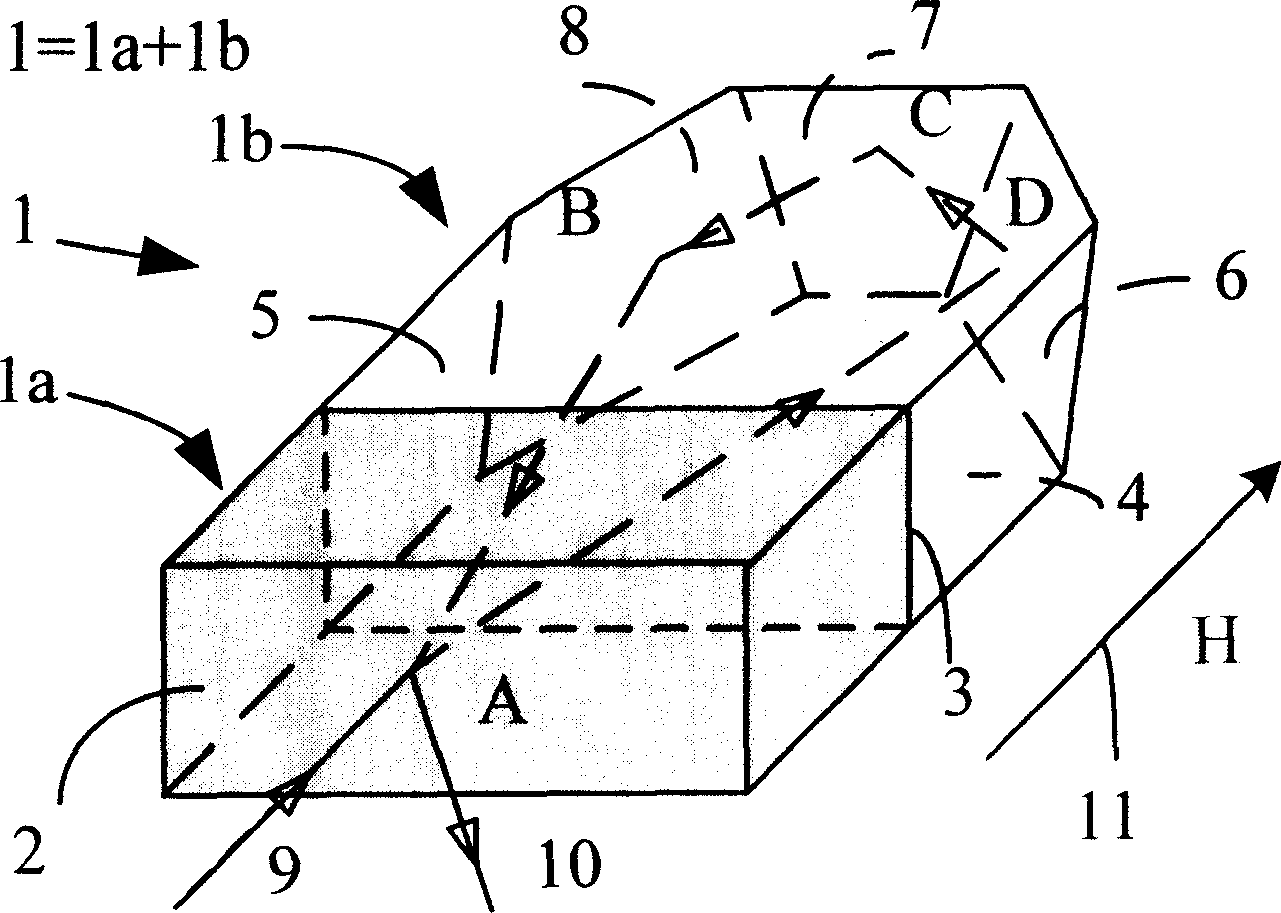

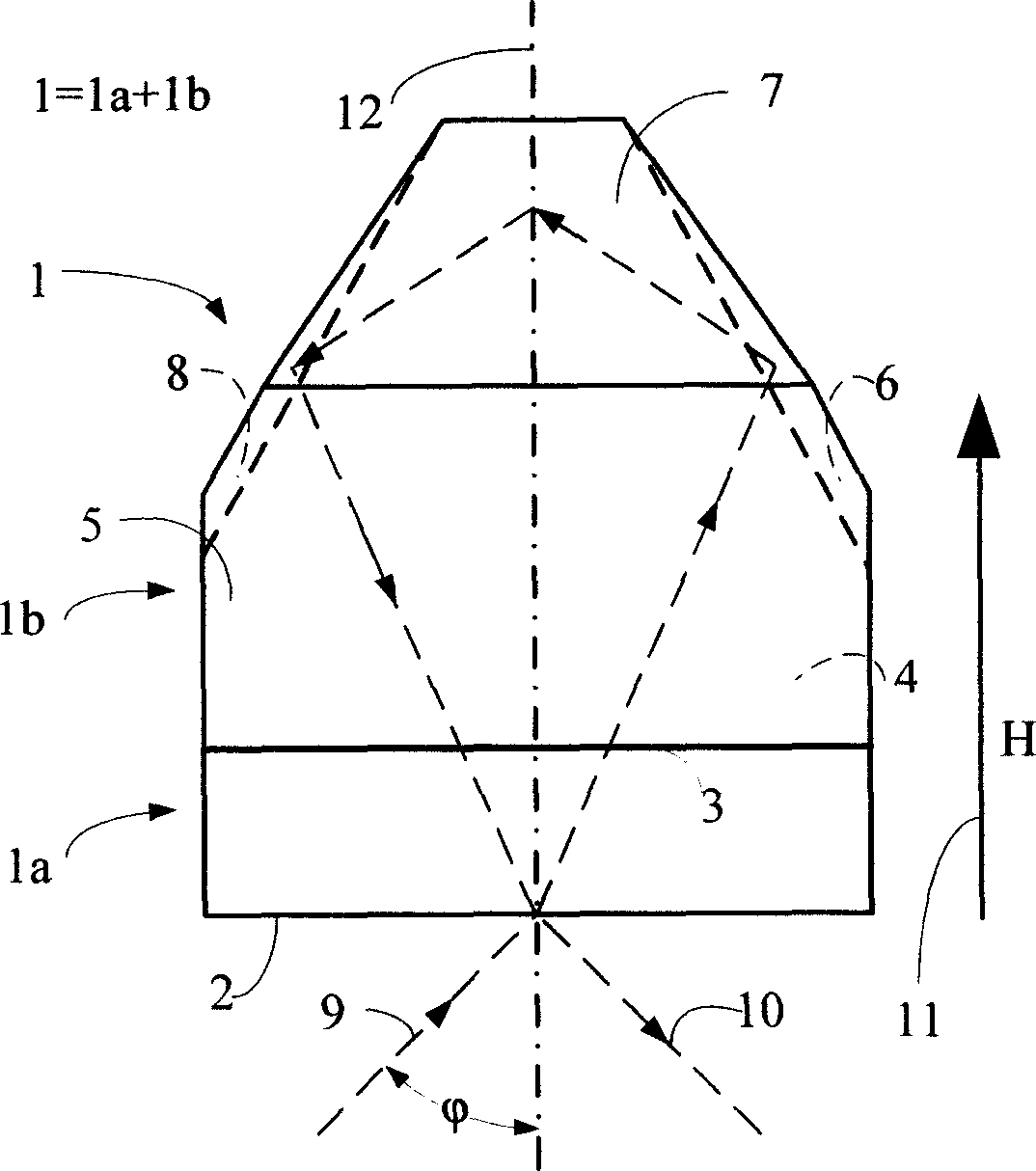

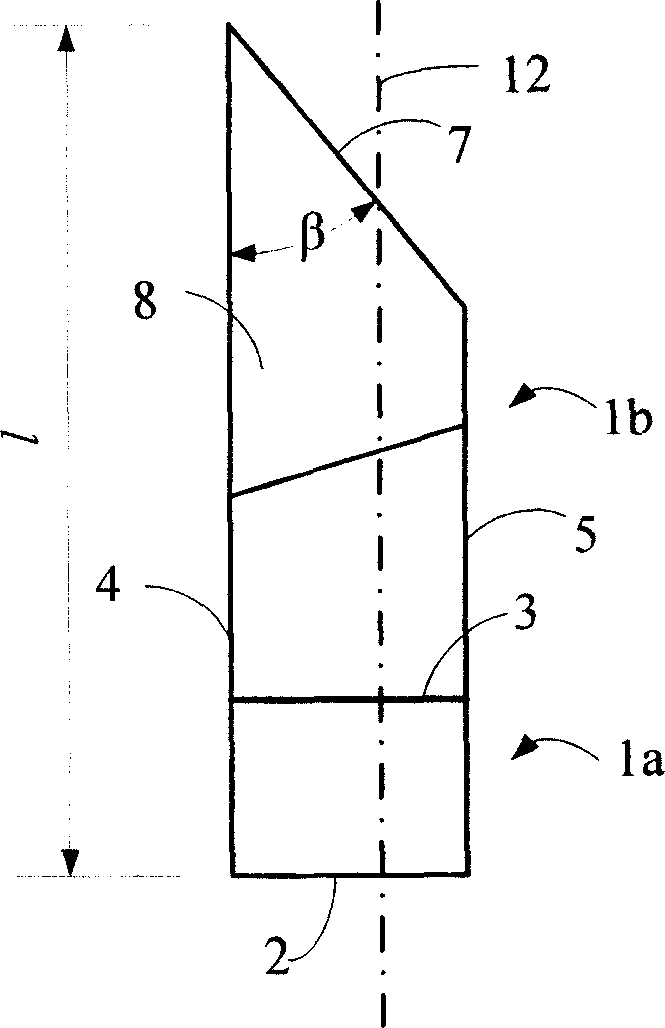

[0011] Example 1: figure 1 It is a schematic diagram of the structure of a bonded monolithic non-planar ring cavity to achieve 2μm single longitudinal mode laser oscillation. The 2μm laser crystal (1a) and the non-doped crystal (1b) are bonded into a monolithic laser crystal (1) to form the resonant cavity of the laser. Point A is both the incident point of the pump light (9) and the exit point of the oscillating laser light (10), using the phase delay of the light wave on the total reflection surface of the points B, C and D in the cavity, introduced by the external magnetic field H Faraday rotation effect, and by coating on the crystal end face (2) where point A is located, the light waves propagating clockwise and counterclockwise in the cavity have different intrinsic polarization states, and the s-polarized light in each direction and The p-polarized light has different reflection coefficients for the output surface, and finally a certain polarization state in one directi...

Embodiment 2

[0012] Example 2: figure 1 It is also a schematic diagram of the structure of a quasi-monolithic non-planar ring cavity that realizes 2μm single longitudinal mode laser oscillation. The 2μm laser crystal (1a) is coated with an anti-reflection coating on the end face (3), and the end face (3) of the non-doped crystal (1b) is also coated The oscillating light anti-reflection coating is closely attached to form a quasi-monolithic laser crystal (1). The point A on the 2μm laser crystal (1a) is not only the incident point of the pump light (9) but also the exit point of the oscillating laser (10). Retardation, the Faraday rotation optical effect introduced by the external magnetic field H, and by coating the crystal end face (2) where point A is located, the light waves propagating clockwise and counterclockwise in the cavity have different intrinsic polarization states, and The s-polarized light and p-polarized light in each direction have different reflection coefficients for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com