Semiconductor double end face pumping Nd:YV04 high power single-mode solid laser

A solid-state laser, double-end face technology, applied in the laser field, can solve the problems of low laser power, occupying the space of the laser, low laser power, etc., and achieve the effect of high optical-to-optical conversion efficiency, reduced adjustment difficulty, and high beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

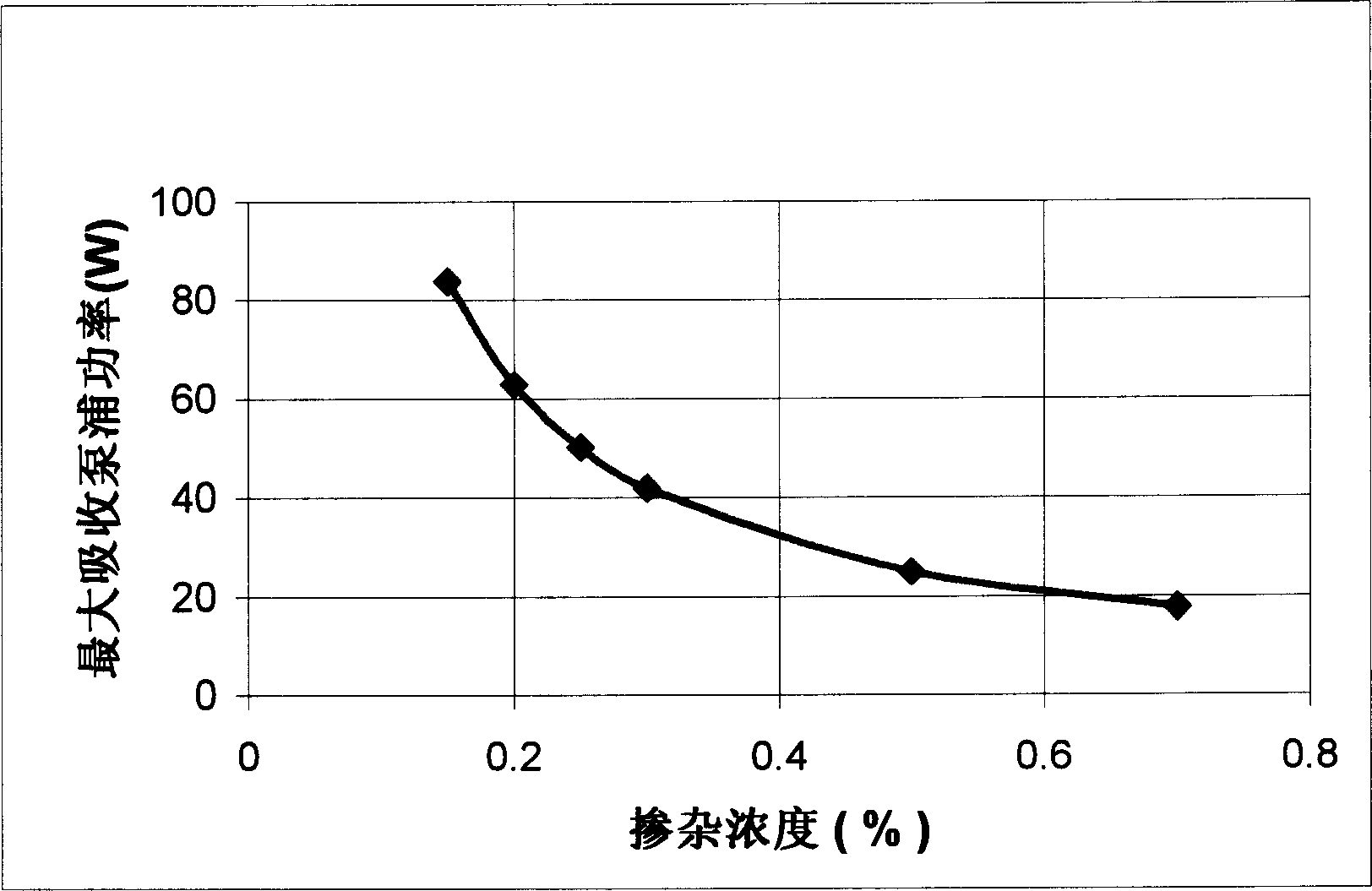

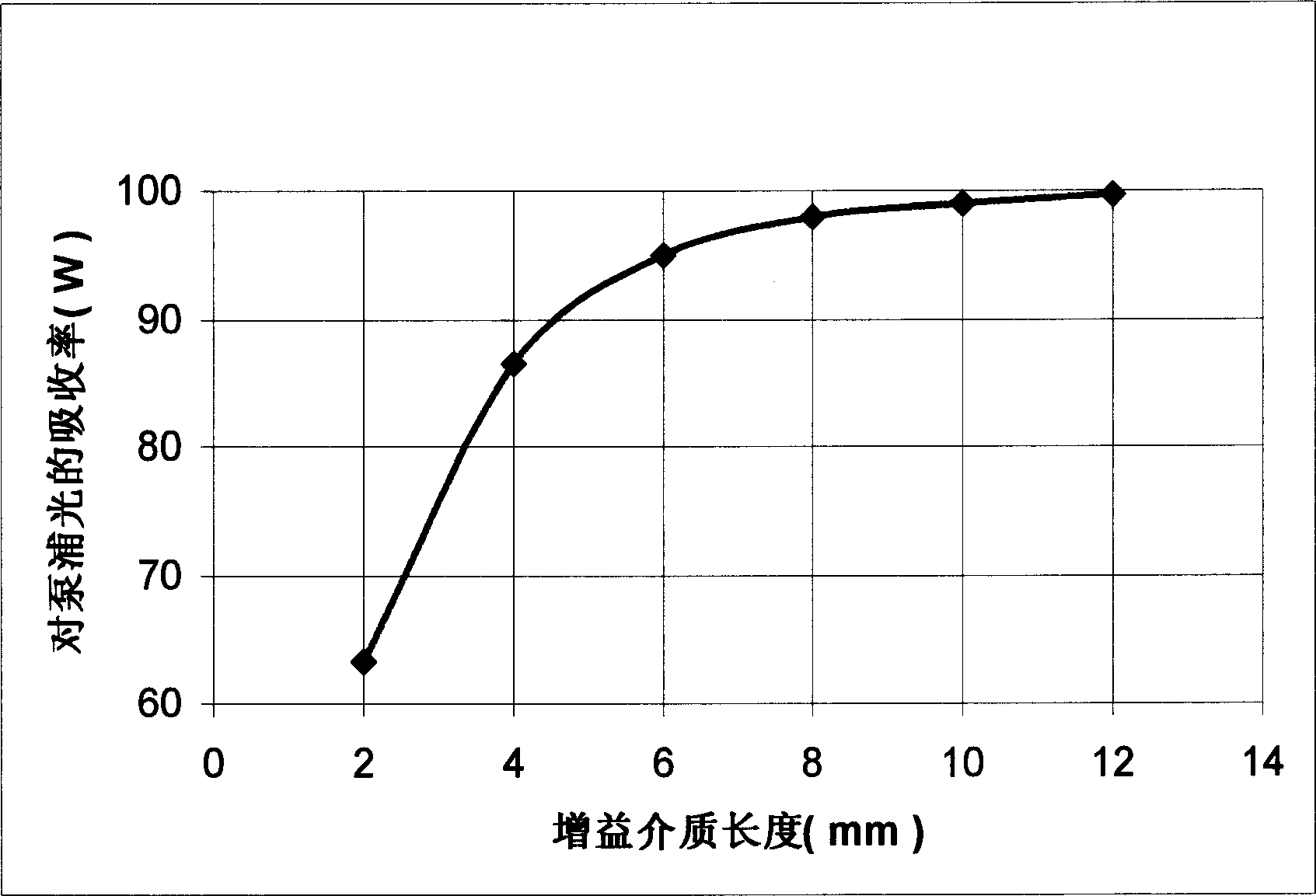

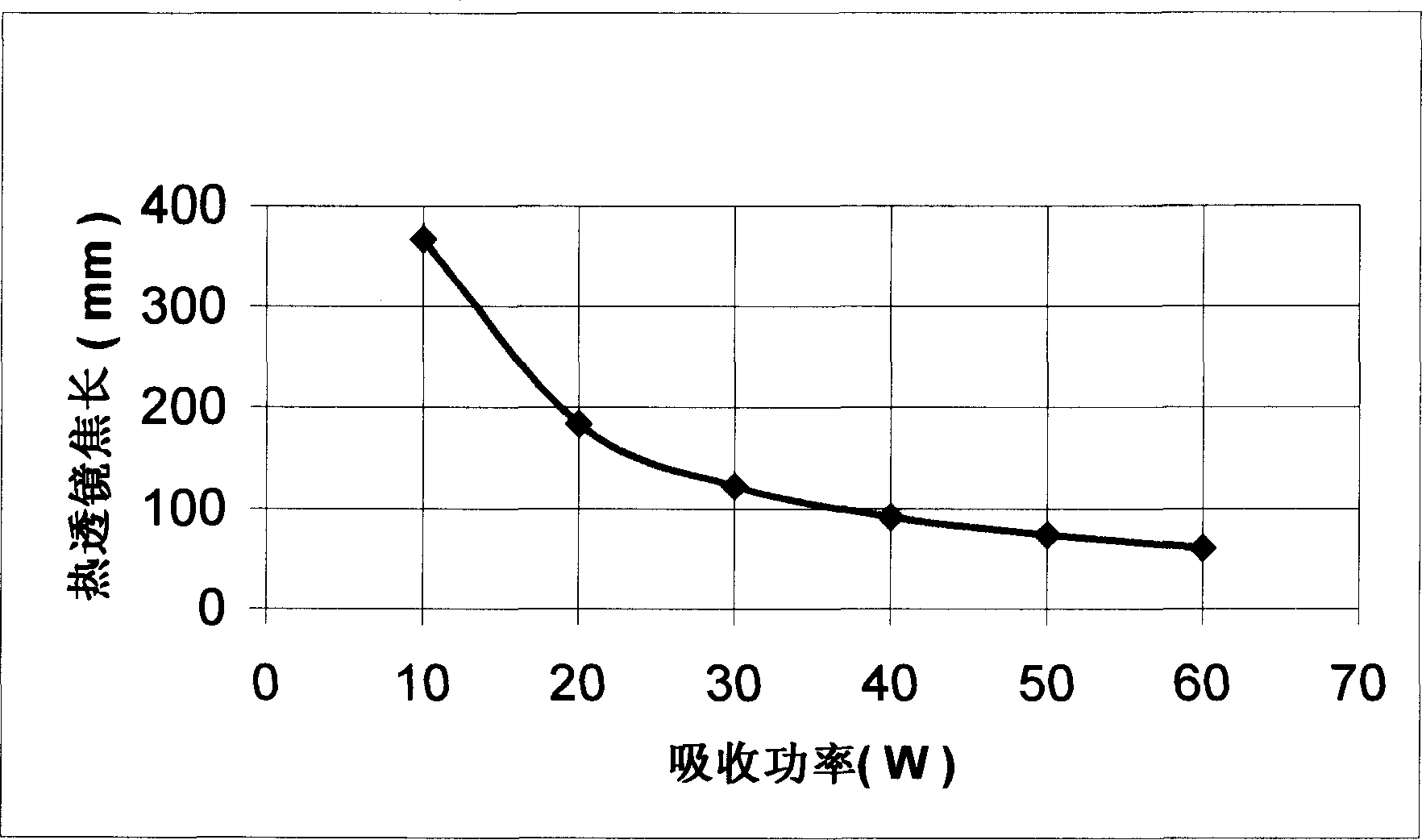

[0024] In the patent of this invention, in order to make the laser work continuously and reliably, we have theoretically designed the relevant parameters of the laser in detail. First, the relationship between the maximum pump power per unit area and the doping concentration that Nd:YVO4 crystals can withstand when they reach thermal stress failure is calculated theoretically (see figure 1 ), it is found that with the increase of doping concentration, the maximum pump power that the crystal can withstand decreases. In order to make the laser work reliably for a long time, Nd:YVO4 crystal with appropriate doping concentration must be selected; under this doping concentration, In order to effectively convert the pump power into laser power, we have calculated the absorption rate of the pump light in Nd:YVO4 crystals at different lengths in detail, as shown in figure 2 As shown, the appropriate crystal length can be selected; after determining the relevant parameters of the crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com