Preparation method of full biodegradation polyester copolymer

A fully degradable, copolymer technology, applied in the field of polymer materials, to achieve the effect of solving the loss of raw materials, fast degradation speed, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

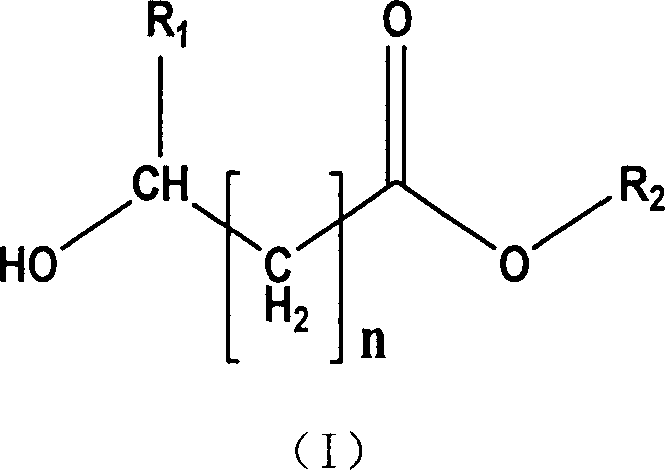

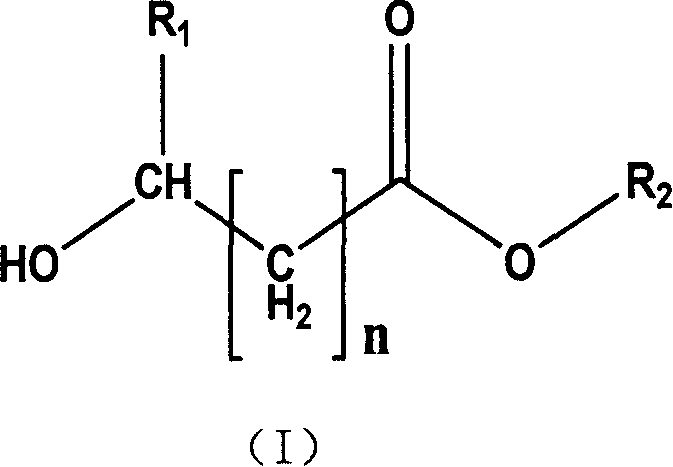

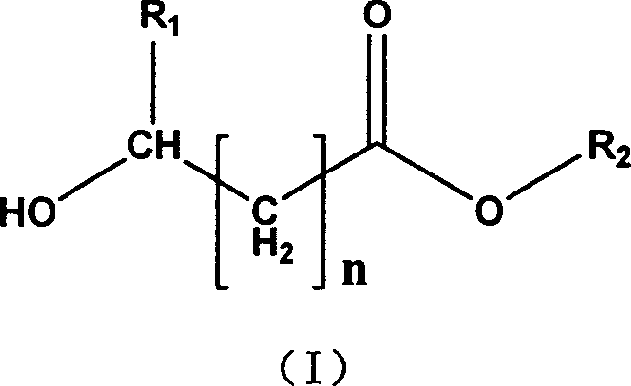

Method used

Image

Examples

Embodiment 1

[0031] Put 200g of LLA refined and purified by ethanol recrystallization into a vacuum reactor, add 0.1g of germanium chloride, vacuumize, control the pressure of the reactor at 1.5kpa, raise the temperature of the reactor to 120°C, and react for 3 hours; Rising to 160°C, the pressure dropped below 100Pa, and continued to react for 3 hours; N 2Rise to normal pressure under protection, add 800g methyl 3-hydroxypropionate and 0.4g tetrabutyl titanate, evacuate to 1.5kpa, and react at 120°C for 3 hours; the temperature of the reactor rises to 160°C, and the pressure drops to 100pa Below, continue to react for 12 hours, N 2 Discharge under protection, get M W =(1~2)×10 5 High molecular weight poly(3-hydroxypropionic acid-co-lactic acid) copolymer.

Embodiment 2

[0033] Put 800g of DLLA refined and purified by ethanol recrystallization into a vacuum reactor, add 0.4g of stannous chloride, vacuumize, control the pressure of the reactor at 1.5kpa, raise the temperature of the reactor to 120°C, and react for 3 hours; The temperature rises to 160°C, the pressure drops below 100 Pa, and the reaction continues for 3 hours; N 2 Rise to normal pressure under protection, add 200g methyl 3-hydroxybutyrate and 0.1g tetrabutyl titanate, evacuate to 1.5kpa, and react at 120°C for 3 hours; the temperature of the reactor rises to 160°C, and the pressure drops to 100pa Below, continue to react for 12 hours, N 2 Discharge under protection, get M W =(1~2)×10 5 High molecular weight poly(3-hydroxybutyrate-co-lactic acid) copolymer.

Embodiment 3

[0035] Put 500g of LLA refined and purified by ethanol recrystallization method, DLLA300g into the vacuum reactor, add 0.4g of germanium chloride, vacuumize, control the pressure of the reactor at 1.5kpa, raise the temperature of the reactor to 120°C, and react for 3 hours; The kettle temperature rises to 160°C, the pressure drops below 100 Pa, and the reaction is continued for 3 hours; N 2 Rise to normal pressure under protection, add 200g glycolic acid and 0.1g stannous chloride, vacuum to 1.5kpa, react at 120°C for 3 hours; raise the temperature of the reactor to 160°C, drop the pressure below 100pa, and continue to react for 12 hours , N 2 Discharge under protection, get M W =(1~2)×10 5 High molecular weight poly(glycolic acid-co-lactic acid) copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com