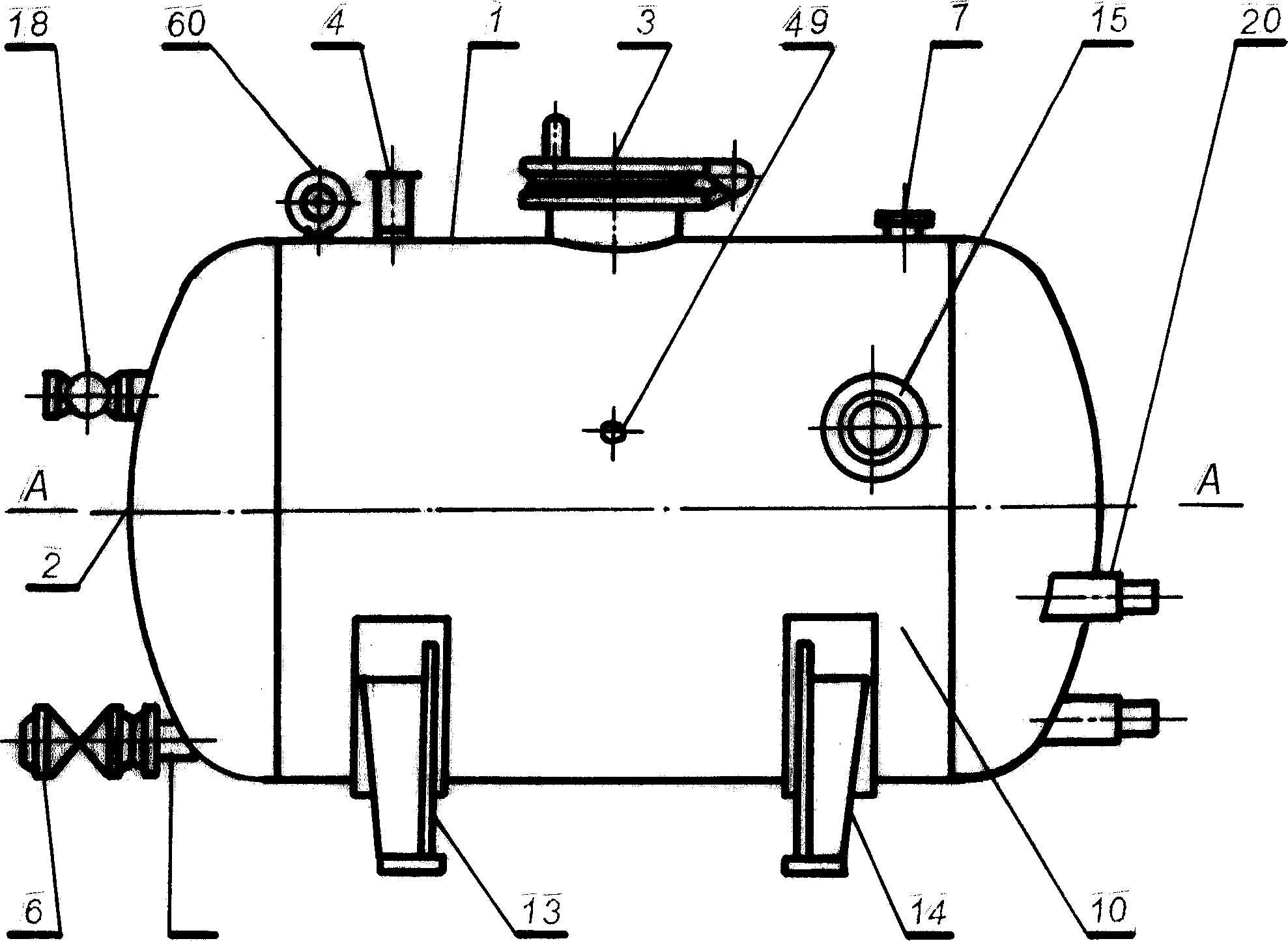

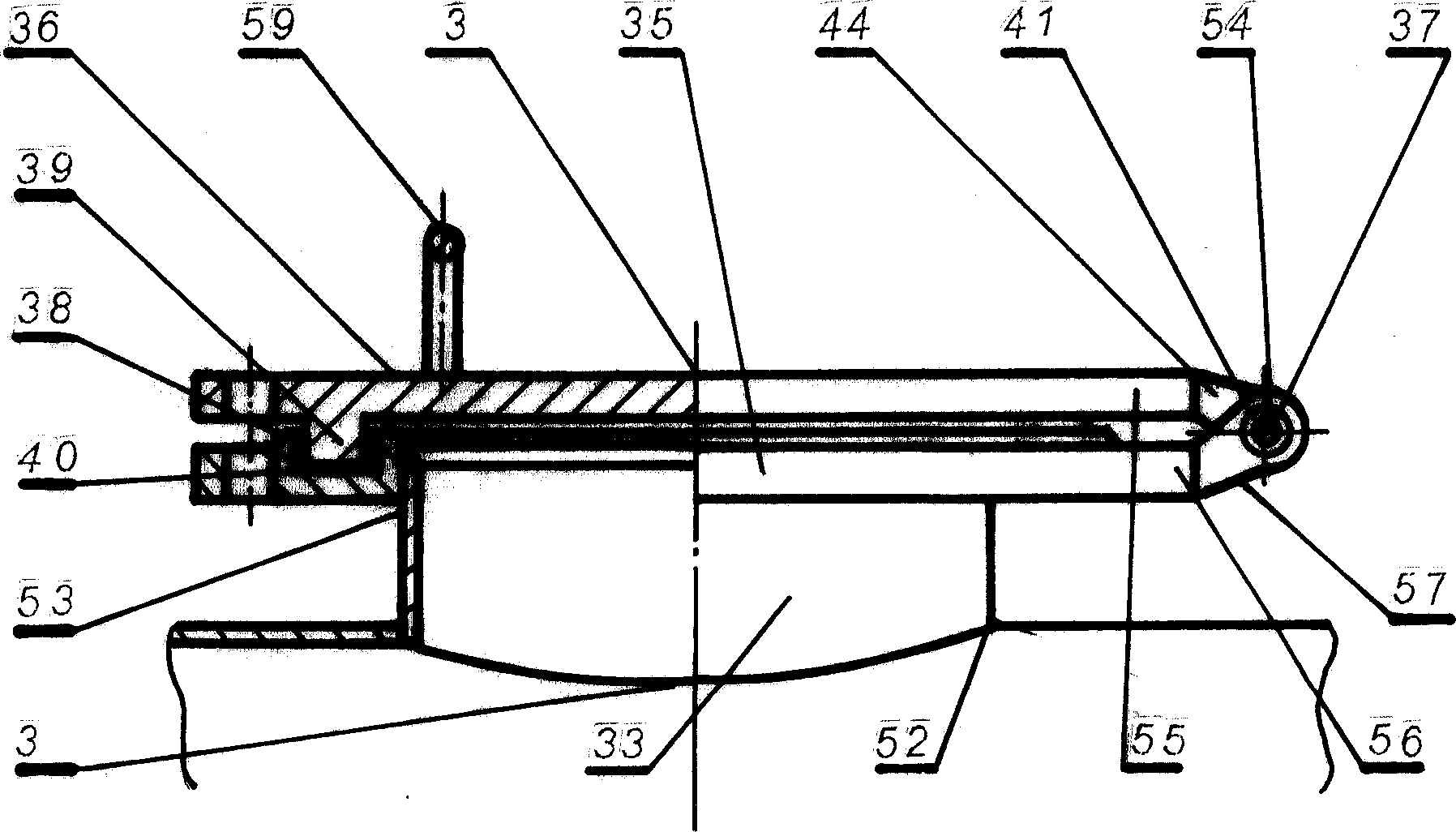

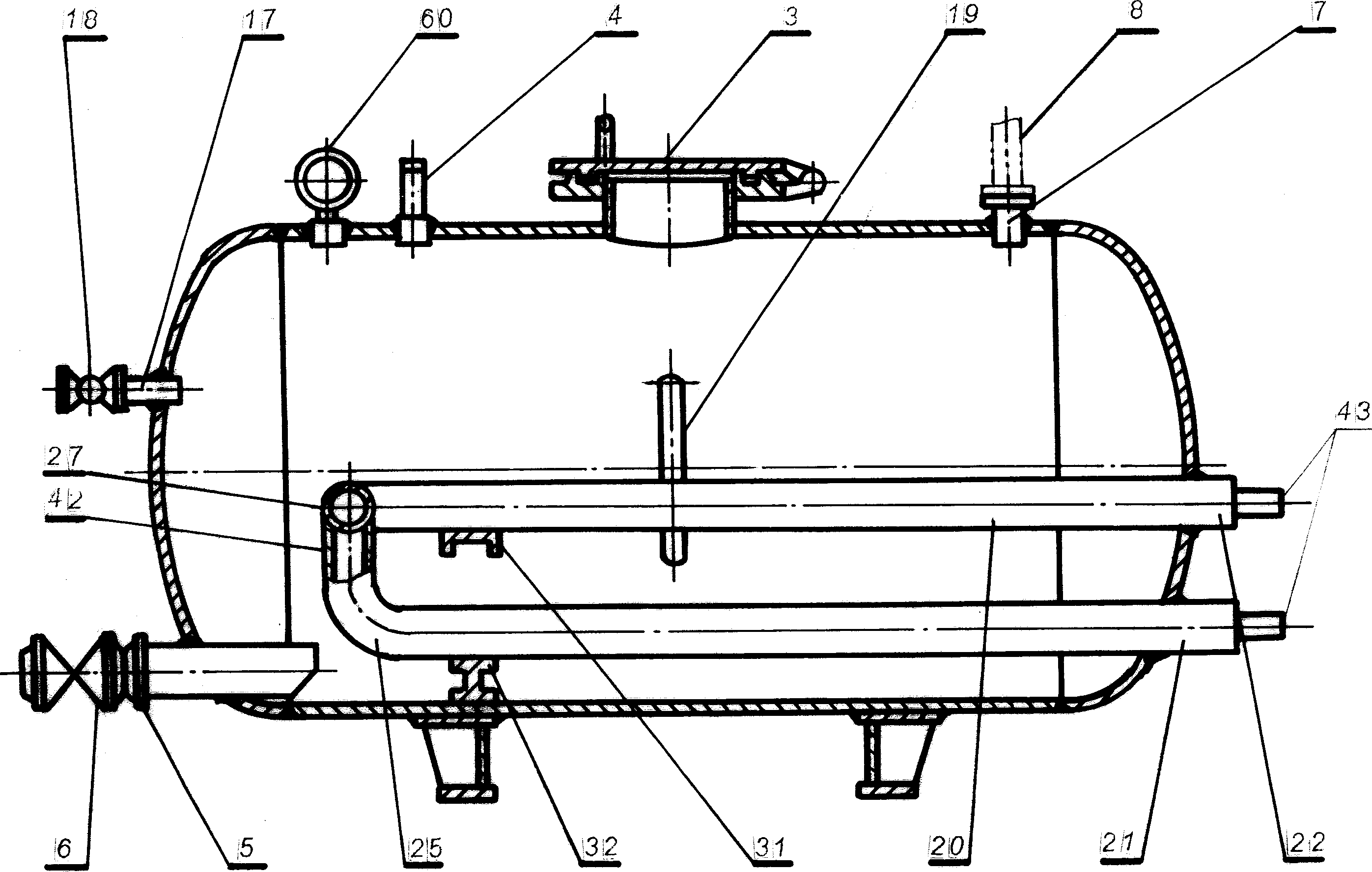

Large and medium sized solar energy marsh gas fermentation tank

A biogas fermentation and solar energy technology, applied in gas production bioreactors, biochemical instruments, biosynthesis, etc., can solve the problems of difficult control of construction quality, unqualified construction quality, and unguaranteed economic benefits, and improve the gas production rate. and raw material utilization, safe and reliable management and maintenance, and simple and easy management and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] 1. Installation and commissioning After the production of the biogas fermentation tank is completed, the installation and commissioning can be carried out after purchasing the instruments, valves and related auxiliary equipment. The sequence is: (1) Before installation, pour a hard and firm foundation pier with reinforced concrete for long-term Bear the full weight of the tank and its contents, do not allow deflection and prevent overturning. (2) Place the tank body in an east-west direction, and then build a slope-type solar glass house to cover the tank body in the room, so as to make full use of sunlight to heat the fermentation material liquid in the tank. (3) Install pressure gauges, all valves, and temperature detectors on the tank body, close the manhole, and connect the peripheral feed pump, gas supply pipeline and automatic pressure regulating gas supply equipment. (4) Pressure debugging, first open the feed valve, close other valves, then use the feed pump to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com