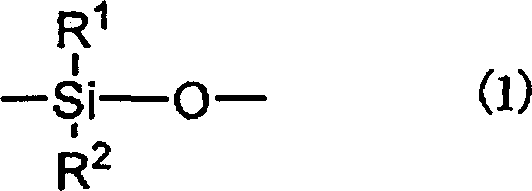

Liquid curable resin composition, cured film and multilayer body

A technology of curable resin and composition, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems such as difficulty in reducing costs, and achieve improved identification, excellent adhesion, and abrasion resistance. damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0211] Manufacture of hydroxyl-containing fluoropolymers

[0212] After fully replacing a stainless steel autoclave with an internal volume of 1.5 L with an electromagnetic stirrer with nitrogen, 500 g of ethyl acetate, 75.4 g of perfluoro(propyl vinyl ether), 34 g of ethyl vinyl ether, 41.6 g of ethyl acetate were added. Hydroxyethyl vinyl ether, 50 g of "AdekaReasoap" (manufactured by Asahi Denka Industry Co., Ltd.) as a nonionic reactive emulsifier, 7.5 g of "VPS-1001" as an azo group-containing polydimethylsiloxane (manufactured by Wako Pure Chemical Industries, Ltd.) and 1.25 g of lauroyl peroxide were cooled to -50°C with dry ice-methanol, and then the oxygen in the system was removed with nitrogen.

[0213] Next, 99.1 g of hexafluoropropylene was added, and the temperature was started. When the temperature inside the autoclave reaches 60°C, the pressure is shown as 5.3×10 5 Pa. It was then stirred at 70 °C for 20 hours, and the reaction was continued until the pressu...

Embodiment 1

[0218] Production of liquid curable resin composition 1

[0219] 5.6 g of the hydroxyl group-containing fluoropolymer obtained in Production Example 1, 1.7 g of methoxylated methylmelamine "Saimel 303" (manufactured by Mitsui Techtec Co., Ltd.) as a thermosetting compound, and 0.63 g of a "Kitaristo 4050" (manufactured by Mitsui Techtec Co., Ltd., aromatic sulfonic acid compound, active ingredient concentration 32%) and 1.3 g of hydrophobic colloidal silica with a number-average particle size of 11 nm were dissolved in 211 g of solvent acetone to obtain a liquid Curable resin composition 1. The solid content concentration in the liquid curable resin composition 1 was 4.0% by mass.

Embodiment 2、3 and comparative example 1、2

[0221] Preparation of Liquid Curable Resin Compositions 2 to 5

[0222] Liquid curable resin compositions 2 to 5 were prepared in the same manner as in Example 1, except that the solvent was changed as shown in Table 1. Table 1 shows the solid content concentration of the obtained liquid curable resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com