Synthesis of high-purity compact block aluminium titanium nitride ceramic material by discharge plasma sintering process

A discharge plasma and aluminum titanium nitride technology, which is applied in the field of ion sintering process to synthesize high-purity dense aluminum titanium nitride ceramic materials, achieves the effects of high yield, simple raw materials, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

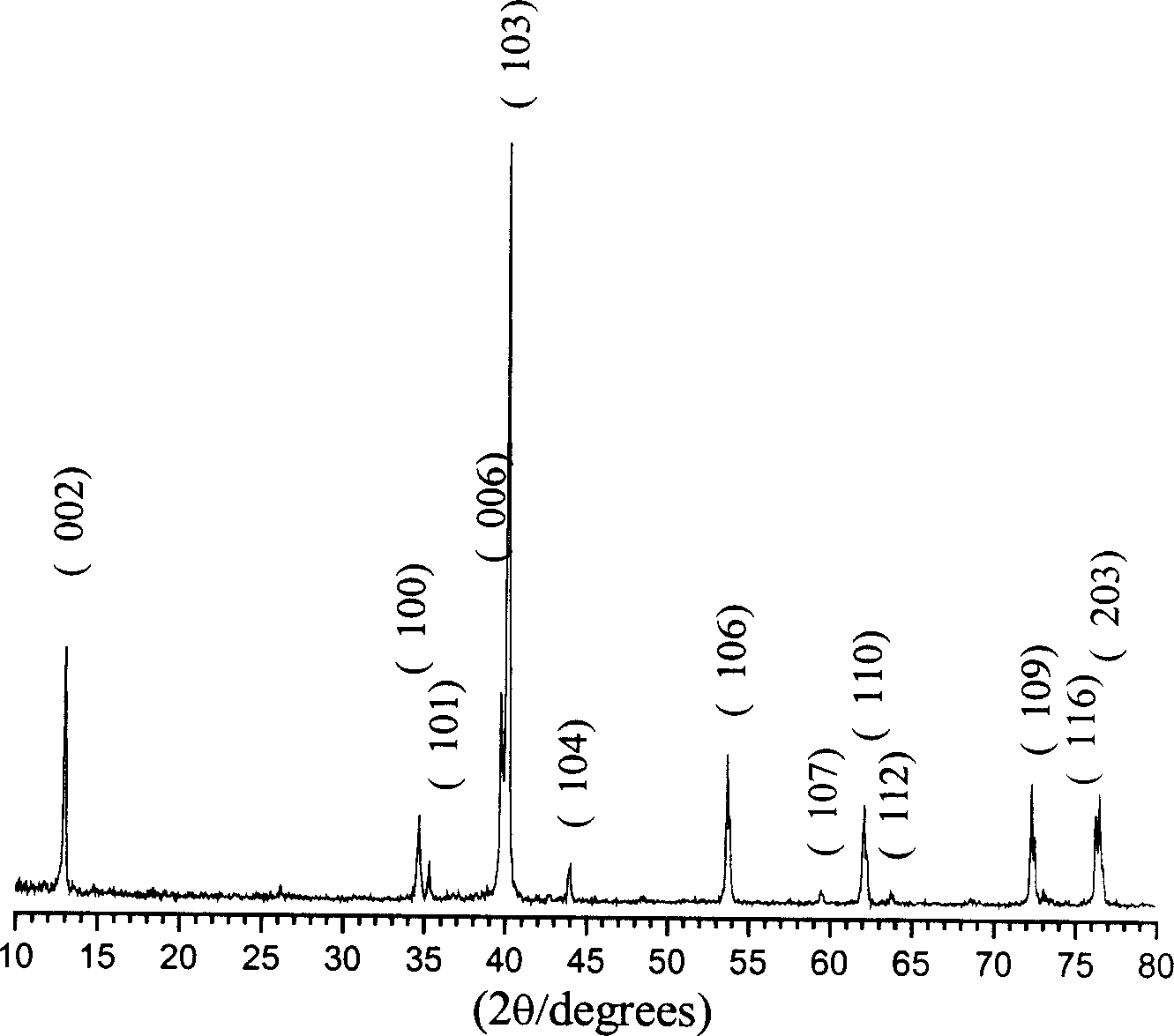

Image

Examples

Embodiment 1

[0024] Embodiment 1: The molar ratio of raw material powder is n(Ti):n(Al):n(TiN)=1:0.8:1.2; mix evenly, put into graphite mold, sinter in spark plasma sintering system, vacuum The degree is 2Pa. Rapidly raise the temperature to 600°C within 3 minutes, and after 600°C, at a heating rate of 80°C / min, the sintering temperature is 1100°C, and the temperature is kept at 30 MPa for 5 minutes. The density of the bulk material is 95.5%, Ti 2 The AlN content is 92%, measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥500MPa, K IC ≥8MPa·m 1 / 2 .

Embodiment 2

[0025] Embodiment 2: The molar ratio of the raw material powder is n(Ti):n(Al):n(TiN)=1:1.2:0.7; mix evenly, put it into a graphite mold, in a hot pressing sintering system, in argon protection For sintering, the vacuum degree is 5Pa. The heating rate is 80°C / min, the sintering temperature is 1350°C, the pressure is 40MPa, and the temperature is kept for 80 minutes. The density of the bulk material is 97.2%, Ti 2 The AlN content is 87%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥500MPa, K IC ≥8MPa·m 1 / 2 .

Embodiment 3

[0026] Embodiment 3: The molar ratio of the raw material powder is n(Ti):n(Al):n(TiN)=1:0.6:1.8; mix evenly, put it into a graphite mold, in a hot press sintering system, in argon protection For sintering, the vacuum degree is 3Pa. The heating rate is 80°C / min, the sintering temperature is 1450°C, the pressure is 10MPa, and the temperature is kept for 40 minutes. The density of bulk material is 94.1%, Ti 2 The AlN content is 87%. Measured on the INSTRON-1195 million mechanical testing machine, the compressive strength of the material is ≥800MPa, and the three-point bending strength σ b ≥500MPa, K IC ≥8MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com