Hyperbranched great macromonomer, acrylate resin containing hyperbranched structure and preparation method

A technology of acrylate and macromonomer, which is applied in the fields of hyperbranched macromonomer, acrylate resin containing hyperbranched structure and preparation, and can solve the problems of long reaction time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the synthesis of polyester type hyperbranched monomer

[0037] Using xylene as a solvent, add 92 grams of glycerin to the flask, add 296 grams of phthalic anhydride in batches at 100°C for 0.5 hours to make it slowly react, gradually increase the temperature at 140°C and keep it under reflux for 10 minutes, then cool down, add 98 grams at 100°C Maleic anhydride, gradually warming up to reflux state, keeping for 10 minutes. Cool down and add 402 grams of trimethylolpropane, raise the temperature to reflux state, keep the esterification until the acid value is below 5 mgKOH / g, then add 244 grams of benzoic acid and 200 grams of lauric acid, and continue to reflux to esterify to the acid value below 5 mgKOH / g.

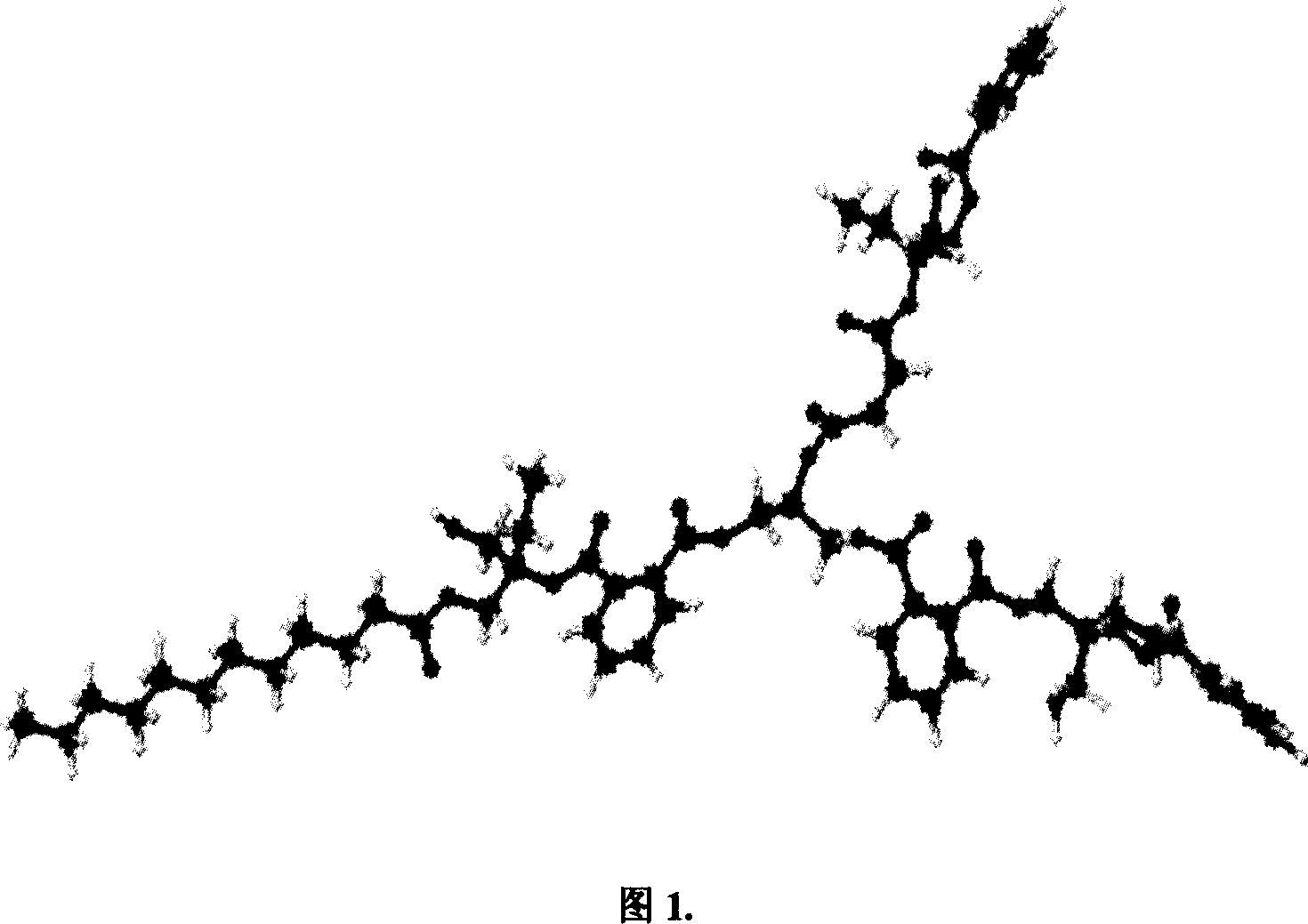

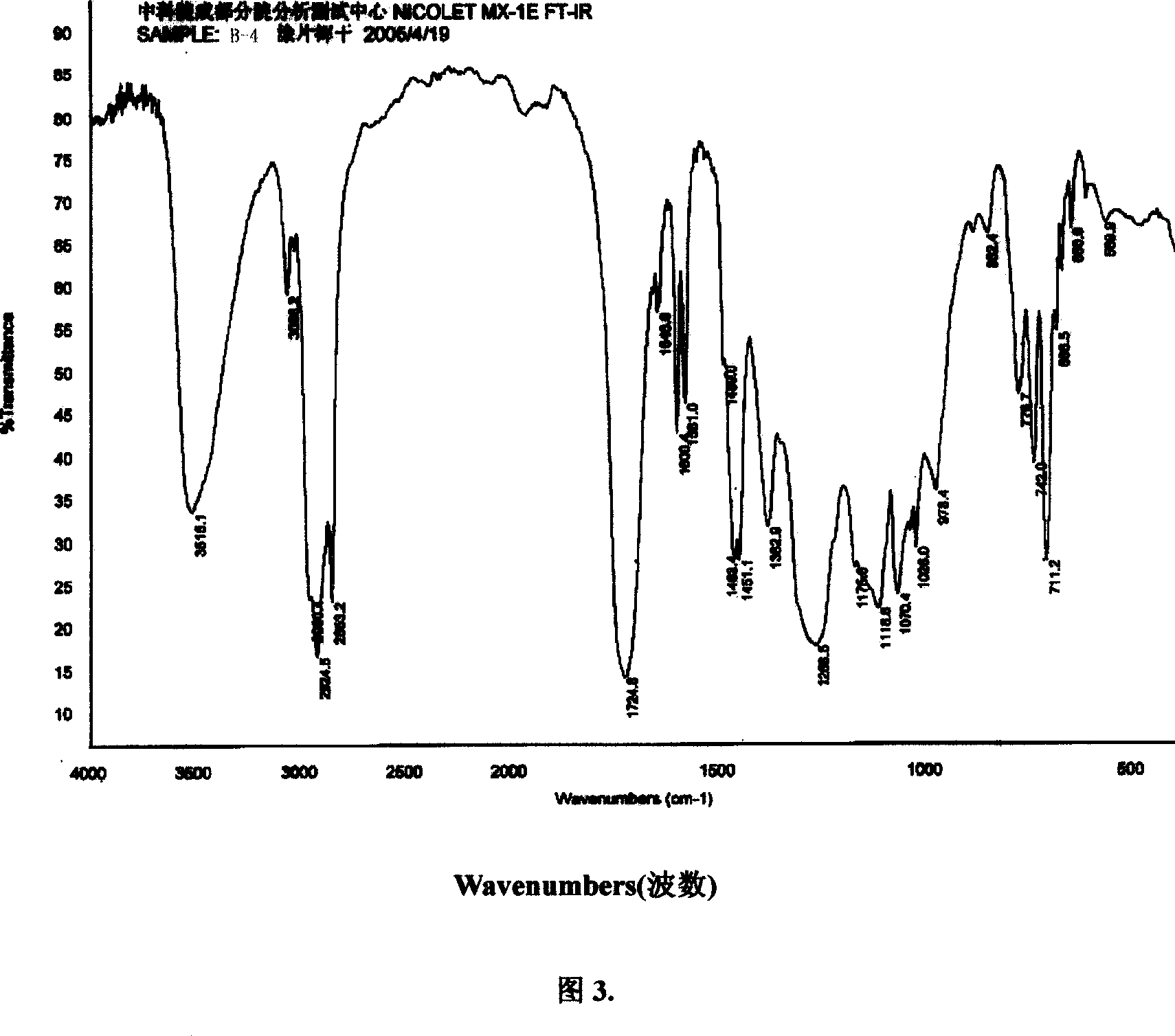

[0038] Its molecular structure is shown in Figure 1, the hydroxyl value and acid value analysis of the intermediate product in the synthesis process is shown in Table 1, and the structural analysis of the product is shown in the infrared spectrum (Fig...

Embodiment 2

[0044] Embodiment 2: the synthesis of polyester type hyperbranched monomer

[0045] Using xylene as a solvent, add 92 grams of glycerin to the flask, add 292 grams of adipic acid in batches at 100°C for 0.5 hours to make it react slowly, gradually raise the temperature to 140-240°C and reflux until the acid value reaches the specified value, cool down, 100 98 g of maleic anhydride was added at ℃, and the temperature was gradually raised to reflux state and kept for 10 minutes. Cool down and add 402 grams of trimethylolpropane, raise the temperature to reflux state, keep the esterification until the acid value is below 5 mgKOH / g, then add 244 grams of benzoic acid and 200 grams of lauric acid, and continue to reflux to esterify to the acid value below 5 mgKOH / g.

Embodiment 3

[0046] Embodiment 3: the synthesis of polyester type hyperbranched monomer

[0047] Using xylene as a solvent, add 92 grams of glycerin to the flask, add 296 grams of phthalic anhydride in batches at 100°C for 0.5 hours to make it slowly react, gradually increase the temperature at 140°C and keep it under reflux for 10 minutes, then cool down, add 98 grams at 100°C Maleic anhydride, gradually warming up to reflux state, keeping for 10 minutes. Cool down and add 402 grams of trimethylolpropane, raise the temperature to reflux state, keep the esterification until the acid value is below 5 mgKOH / g, then add 244 grams of benzoic acid and 284 grams of stearic acid, continue to reflux and esterify to the acid value below 5 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com