High-strength fluid separation medium

A fluid separation, high-strength technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the service life of the filter medium, insufficient filter medium strength, and increasing the energy consumption of the filter equipment, so as not to affect the permeability. Over-rate, increased cross-linking effect, increased strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

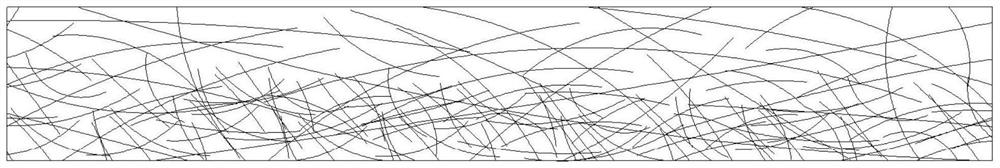

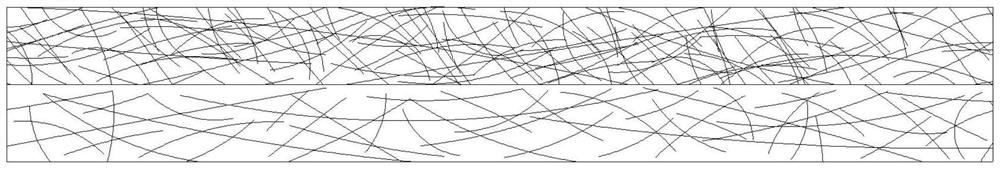

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares high-strength fluid separation medium

[0042] method one:

[0043] 1) get the precursor raw material component of hyperbranched polymer and mix to obtain blend, the precursor raw material of hyperbranched polymer comprises following components:

[0044] A. Skeleton component: one or both selected from aliphatic hyperbranched polyester, aliphatic hyperbranched polyamide, aliphatic hyperbranched polyepoxy resin, aliphatic hyperbranched polyurethane, and hyperbranched polycarbonate;

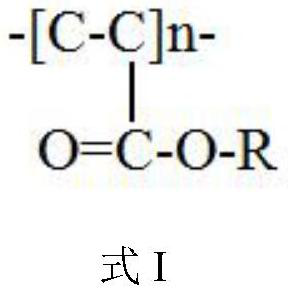

[0045] B. Resin monomer component: selected from acrylamide, N-methylolacrylamide, glycidyl acrylate, glycidyl methacrylate, styrene, hydroxyethyl methacrylate, acrylic acid, methacrylic acid, One or more of hydroxyethyl acrylate, acrylate, methyl acrylate, methyl methacrylate, butyl acrylate, isooctyl acrylate, and ethyl acrylate.

[0046] C. Reaction auxiliary agent: one or more selected from azobisisobutyronitrile, dibenzoyl peroxide, quaternary ammonium salt of te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com