Chelate column for analyzing metal elements and apparatus for samples treatment

A metal element and chelation technology, which is applied in measurement devices, analytical materials, material separation, etc., can solve the problems of complex preparation method of spherical cellulose metal adsorbent, adverse effects of trace metal element analysis operations, and unsatisfactory degree of automation. , to achieve the effect of improving the sample processing speed, simplifying the sample processing process and the structure of the sample processing device, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: The column packing of the chelating column is processed by non-polar macroporous adsorption resin

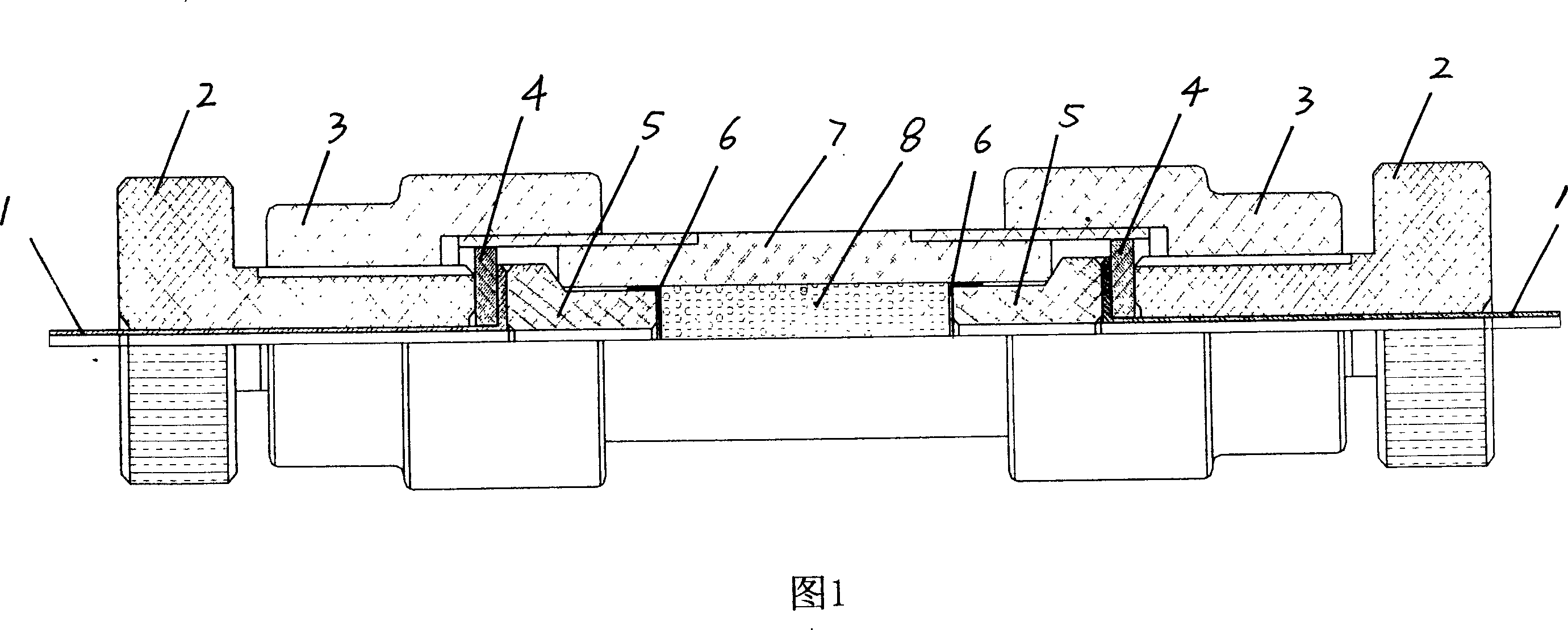

[0032] The structure of the chelating column in the present embodiment is as shown in Figure 1, mainly is made of column body, filter membrane 6 and column filler 8; Column body is made by nylon, comprises column tube 7, the plug 5 that is positioned at column tube lumen two ends 1. Pressure tube bolt 2 for applying pressure to the plug, connecting sleeve 3 connecting the column tube and the pressure tube bolt, a conduit 1 is installed in the center hole of the pressure tube bolt 2, and the insertion end of the conduit 1 is provided with a plug attached to the plug. A disc-shaped body, a sealing ring 4 is installed between the disc-shaped body and the end face of the pressure pipe bolt, the conduit 1 communicates with the center hole of the plug 5 to form a liquid input and output channel; the filter membrane 6 is made of nylon silk, and is installed separately ...

Embodiment 2

[0057] Example 2: The column filler of the chelating column is processed by a medium polar macroporous adsorption resin

[0058] The structure of the chelating column in this example is the same as that in Example 1, as shown in FIG. 1 . The difference from Example 1 is the column packing 8 of the chelating column, and the column packing adopts Amberlite XAD-6, Amberlite XAD-7, and Amberlite XAD-8 medium-polar macroporous adsorption resins produced by U.S. Rohm & Hass to prepare the column packing , the process steps are as follows:

[0059] 1. Soaking swelling and purification

[0060] Put the above-mentioned medium-polarity macroporous adsorption resin in a container filled with ethanol and soak it at 25°C for 8 hours to meet the swelling requirements, then wash the soaked and swollen resin with deionized water until it does not contain up to ethanol.

[0061] 2. Use NH 4 OH-HAC-pyridine-(2-azo-4-)resorcinol mixed solution dynamic column processing

[0062] (1) Preparat...

Embodiment 3

[0083] Embodiment 3: the column filler of chelation column is processed by polar macroporous adsorption resin

[0084] The structure of the chelating column in this example is the same as that in Example 1, as shown in FIG. 1 . The difference from Example 1 is the column packing 8 of the chelating column, and the column packing adopts Amberlite XAD-9, Amberlite XAD-10 polar macroporous adsorption resin produced by Rohm & Hass Company of the United States and NKA pole produced by Nankai University in Tianjin, China. The column packing is prepared by using a permanent macroporous adsorption resin, and the process steps are as follows:

[0085] 1. Soaking swelling and purification

[0086] Put the above-mentioned polar macroporous adsorption resin into a container filled with ethanol and soak it at 25°C for 8 hours to meet the swelling requirements, then wash the soaked and swollen resin with deionized water until it does not contain ethanol until.

[0087] 2. Use NH 4 OH-HAC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com