Halftone phase shift mask blank, halftone phase shift mask, and manufacturing method thereof

一种相移掩膜、半色调的技术,应用在半色调型相移掩膜坯料领域,能够解决刻蚀速度慢、无法获得高精度图案、上层氟系干式刻蚀刻蚀选择不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

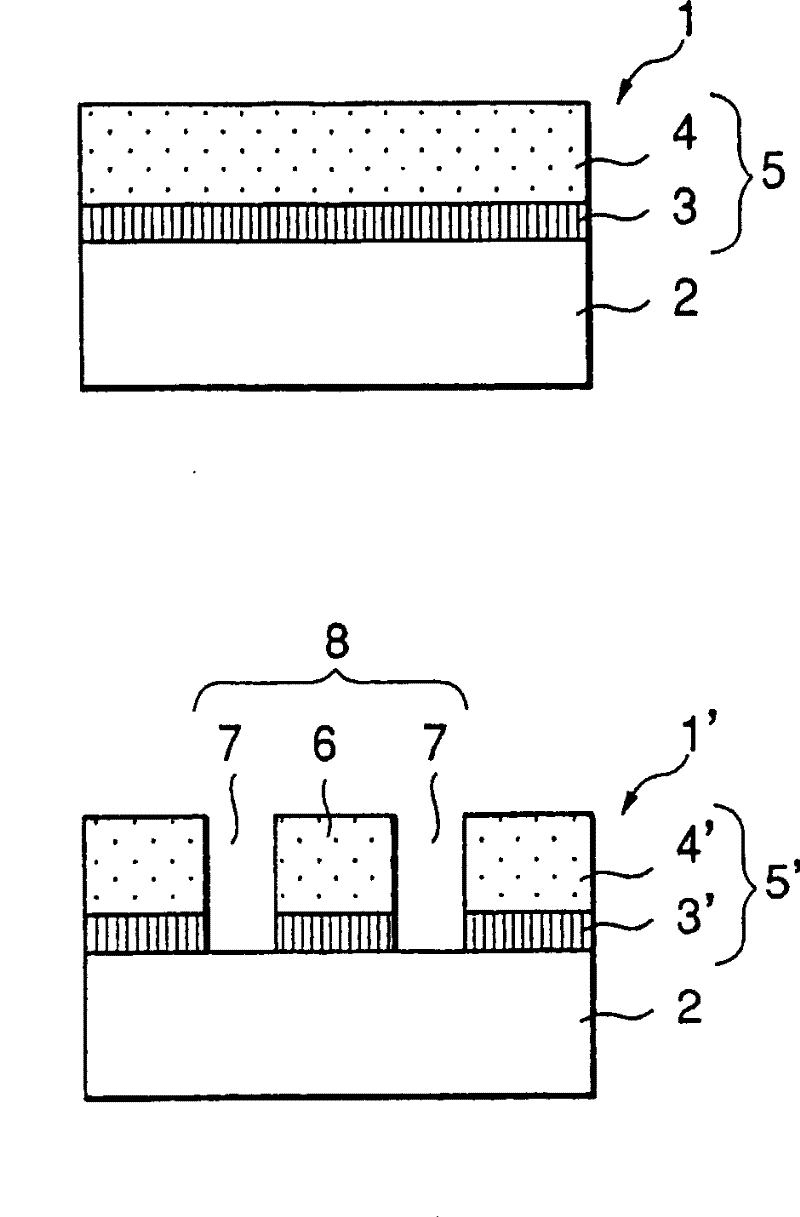

[0143] Embodiment 1~8 is corresponding to F 2 A specific example of a half-tone phase shift mask for excimer laser exposure, the substrate uses a synthetic quartz substrate, and the substrate and SiO x N y An etch stop layer is provided between the layers.

[0144] (film formation)

[0145] First, on a synthetic quartz substrate, etch stop layer A layer, and SiO x N y constitute the B layer. In this embodiment, it is manufactured according to the sputtering method. The basic compositions of layers A and B of the double-layer film in each embodiment, the conditions such as target and sputtering gas type, and the film thickness of each layer are shown in Table 1. The respective film thicknesses of the A layer and the B layer are adjusted using the above formula (1) so that the sum of the phase shift amounts of each layer becomes 180° with respect to a wavelength of 157 nm.

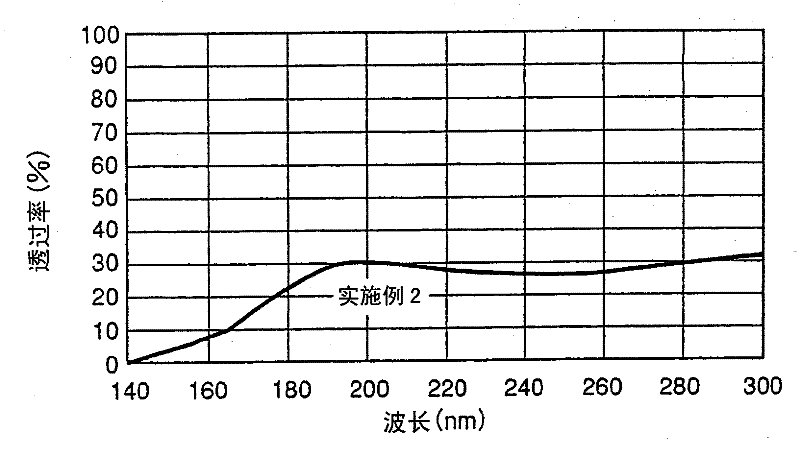

[0146] (optical properties)

[0147] Measure the transmittance of the double-layer film that make...

Embodiment 9

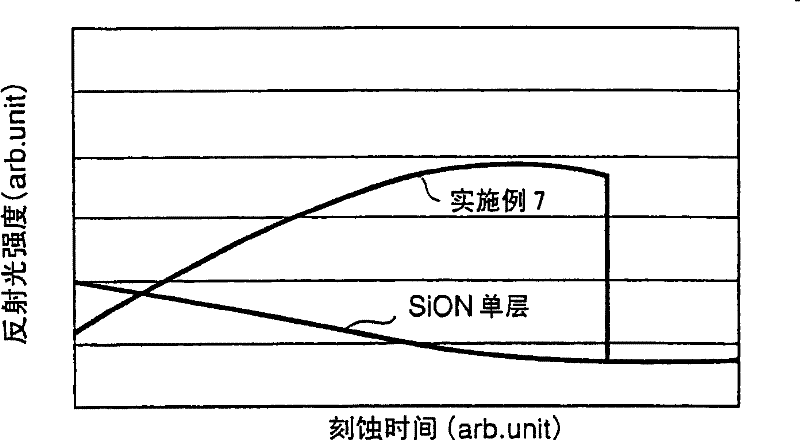

[0166] The underlying material was investigated in this example. Table 5 confirms that when using fluorine-based and chlorine-based gases for dry etching, TaZr x (Indicates the inclusion of Ta and Zr, rather than the composition ratio of Ta and Zr. The same below), and the results of the etching characteristics of Zr. Table 6 shows the results of confirming the etching properties of TaAl and TaHf when performing dry etching using fluorine-based and chlorine-based gases. That is, in this example, the dry etching characteristics of a film in which the main material is Ta and materials (Al, Hf, Zr) considered to be related to the effect of the present invention are added are mainly confirmed.

[0167] table 5

[0168]

[0169] Each film material was formed into a film using a sputtering method. When adding materials, the metal sheet of the target material is placed on the Ta target to form a film. Whether or not it was added to the film was confirmed by X-ray photoelectro...

reference example 1

[0174] In order to confirm the addition effect in Example 9, the dry etching characteristics of a Ta single metal film to which the above materials were not added were confirmed as a reference example. As shown in Table 7, the selectivity between the Ta single metal film and the quartz substrate was not sufficient for the fluorine-based gas. The etching conditions of this comparative example are implemented according to Example 9.

[0175] Table 7

[0176]

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com