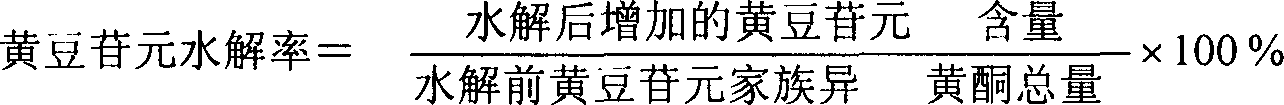

Method of preparing soybean isoflavone aglycone by hydrolyzing enzyme of natural edible raw material

A technology for isoflavone aglycone and isoflavone glycoside is applied in the field of preparing a mixture of soybean isoflavone aglycone and polysaccharide containing two functional factors, and can solve the problems such as many by-products of strong acid hydrolysis, difficult industrialization and unsafe conditions of strong acid. , to achieve the effect of high food safety, low production cost and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a. Commercially available 30% soybean isoflavone powder (Heilongjiang Shuanghe Songnen Soybean Bioengineering Co., Ltd.) is the raw material of soybean isoflavone glycoside, referred to as "substrate A".

[0042] b. At 4-20°C, take commercially available mushroom fruiting bodies, extract with water or 0.025-0.1mol / L phosphate buffer solution or phosphate and citric acid buffer solution, the ratio of solid to liquid is 1:1, and centrifuge to collect the clear water. solution, adjust the pH to 4.0-5.0. The extract containing polysaccharide and hydrolase is obtained, referred to as "aroma enzyme liquid".

[0043] c. Substrate A 2.5g, add 3.7-100.0mL aroma enzyme solution per gram of substrate A. The total reaction volume of soybean isoflavone glycosides hydrolyzed by the enzyme is adjusted to 60-1800mL / g substrate A by dissolving with a buffer solution with a pH value of 4.0-5.0. The reaction is carried out for 2-24 hours, and the reaction conditions are that the tempera...

Embodiment 2

[0046] a. Commercially available 30% soybean isoflavone powder (Heilongjiang Shuanghe Songnen Soybean Bioengineering Co., Ltd.) is the raw material of soybean isoflavone glycoside, referred to as "substrate A".

[0047] b. At 4-20°C, take commercially available Flammulina velutipes fruiting bodies, extract with water or 0.025-0.1mol / L phosphate buffer solution or phosphate and citric acid buffer solution, the ratio of solid to liquid is 1:1, centrifuge to collect clear solution, adjust the pH to 5.0-6.0. The extract containing polysaccharides and hydrolytic enzymes is obtained, referred to as "golden enzyme solution".

[0048] c. Substrate A 2.5g, add 8.0-100.0mL gold enzyme solution per gram of substrate A. The total reaction volume of soybean isoflavone glycosides hydrolyzed by the enzyme is adjusted to 60-1800mL / g substrate A by dissolving with a buffer solution with a pH value of 5.0-6.0. The reaction is carried out for 3 to 24 hours, and the reaction conditions are a te...

Embodiment 3

[0052]a. Commercially available 30% soybean isoflavone powder (Heilongjiang Shuanghe Songnen Soybean Bioengineering Co., Ltd.) is the raw material of soybean isoflavone glycoside, referred to as "substrate A".

[0053] b. Take wheat seeds, soak overnight with excess water, grind and extract with 0.025-0.1mol / L, pH6.6 phosphate buffer solution at 4-10°C, the ratio of solid to liquid is 1:2, and centrifuge to collect the supernatant , adjust the pH value to 5.0-6.0. Then centrifuge to collect the supernatant to obtain an extract containing polysaccharides and hydrolytic enzymes, referred to as "small enzyme liquid".

[0054] c. Substrate A 2.5g, add 8.0-100.0mL small enzyme solution per gram of substrate A. The total reaction volume of soybean isoflavone glycosides hydrolyzed by the enzyme is adjusted to 60-1800mL / g substrate A by dissolving with a buffer solution with a pH value of 5.0-6.0. The reaction time is 12-48 hours, and the reaction conditions are a temperature of 35-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com