Micro electromechanical system chip size airtight packaging vertical interconnecting structure and its manufacturing method

A micro-electromechanical system and hermetic packaging technology, which is applied in the direction of microstructure technology, microstructure devices, and processing microstructure devices, can solve problems such as airtightness and IC process compatibility defects, and achieve protection from damage and increase density. , Reduce the effect of on-resistance and signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

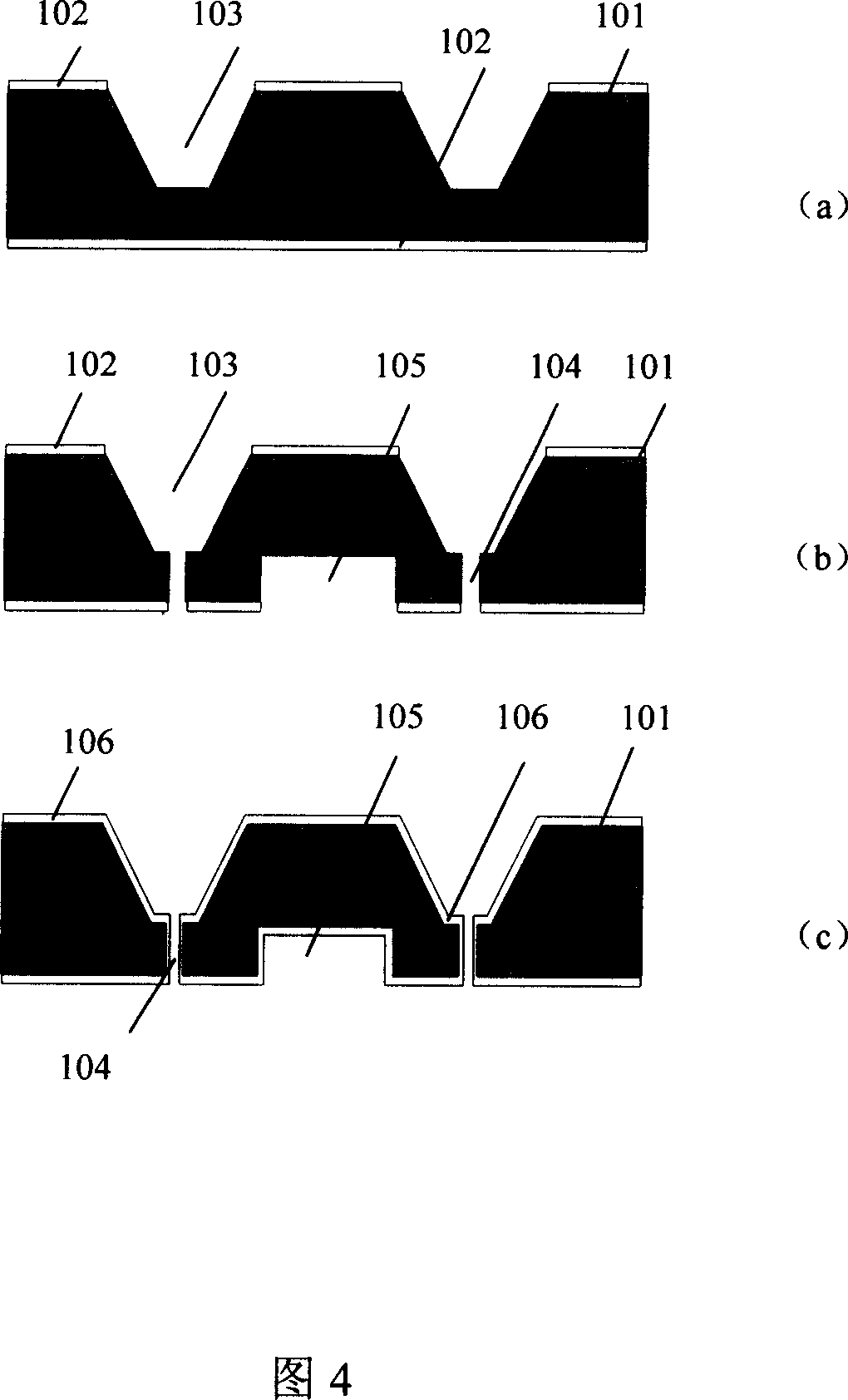

[0037] In order to fully demonstrate the advantages and positive effects of the present invention, the embodiment of n=5 and m=4 will be explained below in conjunction with the accompanying drawings, to further demonstrate the substantive features and remarkable progress of the present invention.

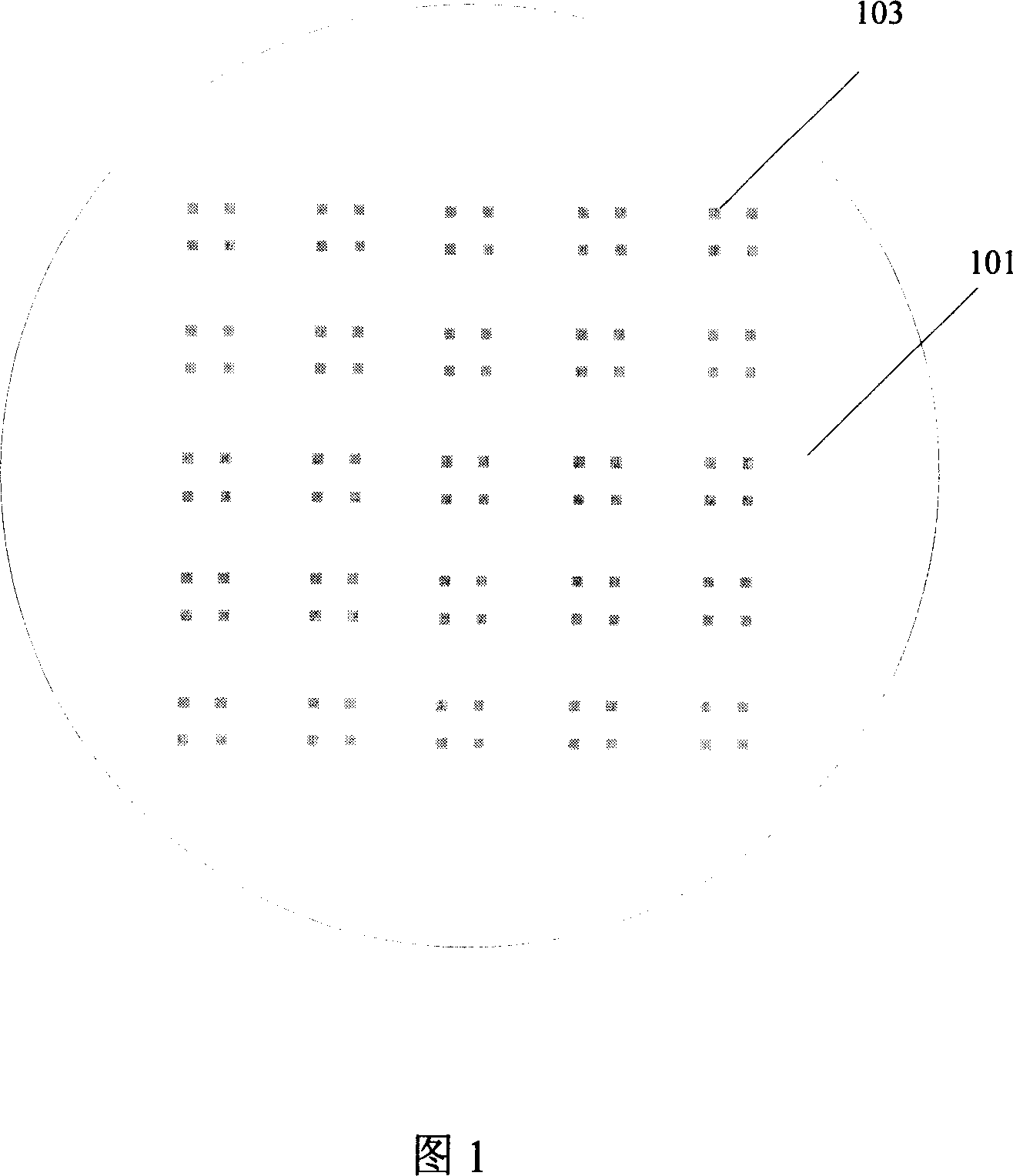

[0038] In FIG. 1 , there is a 5×5 cell array distribution on the front side of the silicon wafer 101 of the cover plate, and each cell has four inclined slots 103 , and the inclined slots 103 are formed by wet etching.

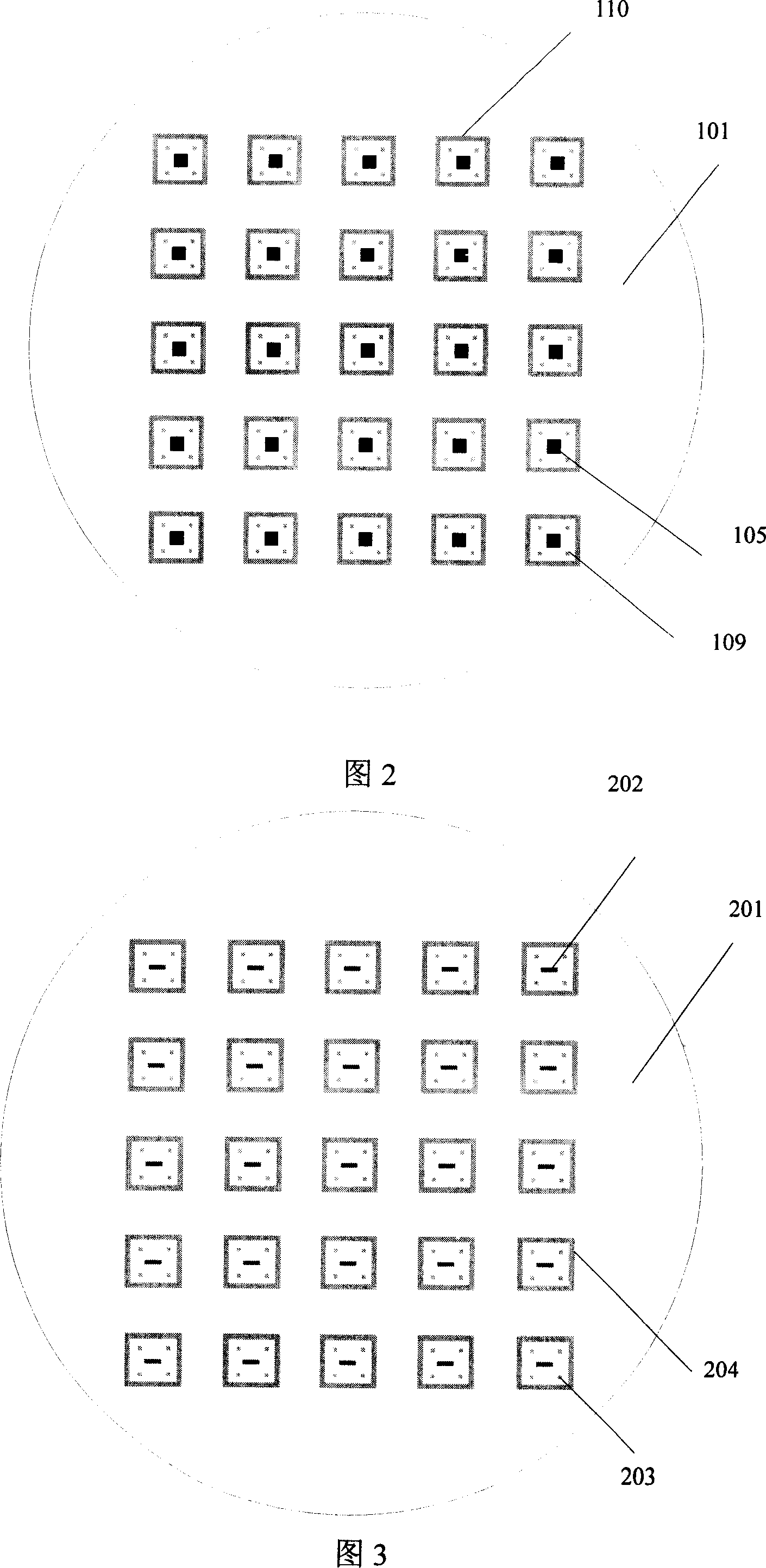

[0039] In Fig. 2, on the back of the cover silicon wafer 101 is a 5×5 cell array distribution corresponding to the front of the cover, and in the middle of each unit is a cavity 105 formed by dry etching, and around the cavity are distributed Four metal pads (pad) 109 are surrounded by a metal sealing ring 110 .

[0040] Fig. 3 is a MEMS substrate 201, inside the substrate is a 5×5 cell array distribution corresponding to the cell array distribution on the back of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com