Production of ethylbenzene by ethane and benzene phase-variable catalytic separation in catalytic dry gas

A catalytic cracking and dry gas technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as pollution, waste of resources and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

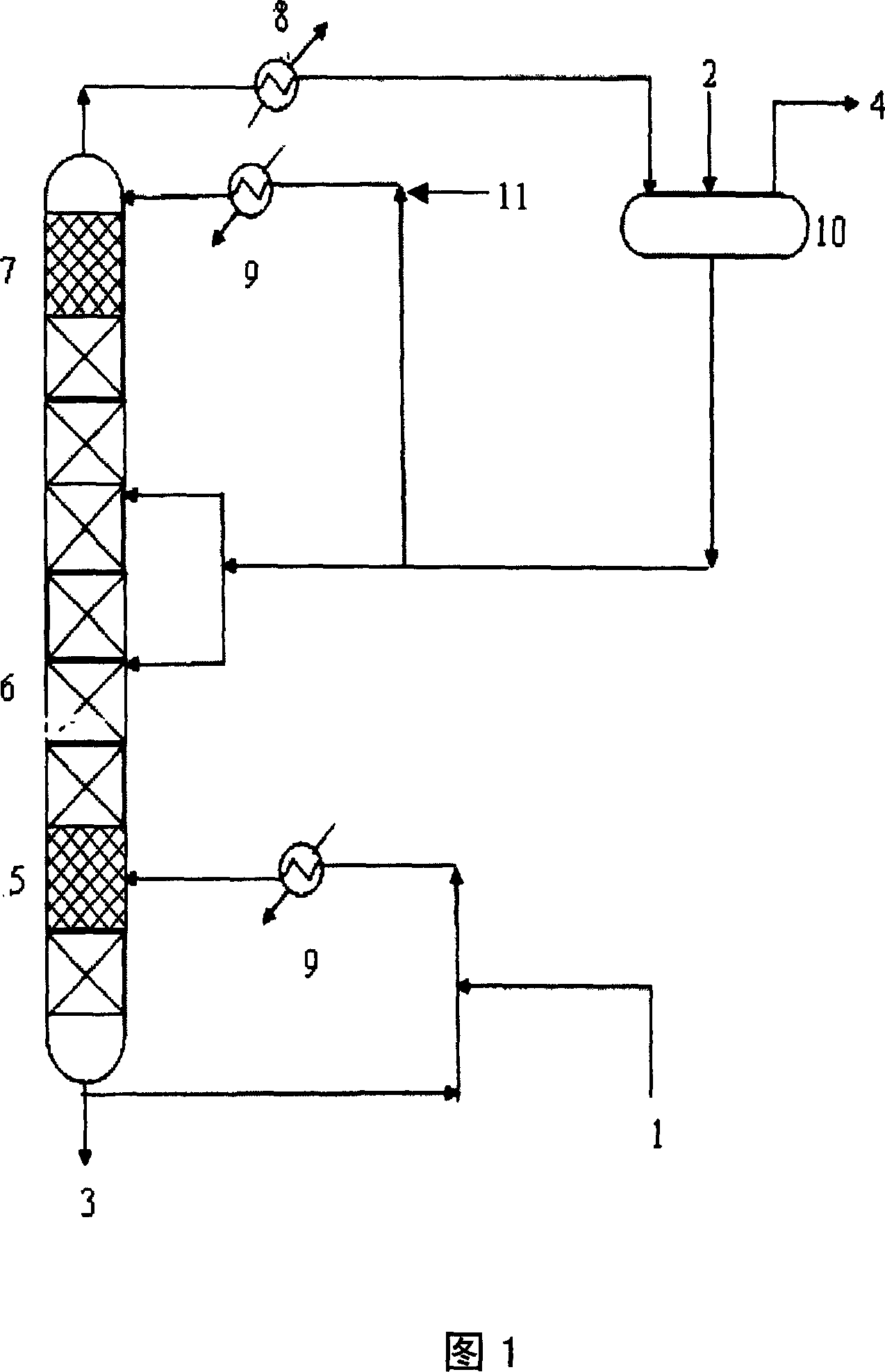

Image

Examples

Embodiment 1-6

[0030]The catalyst used in the reaction is 3994 (Y-type molecular sieve) special-shaped catalyst produced by Fushun Catalyst Factory. The reaction conditions and results are shown in Table 1. It can be seen from the table that within the range of conditions investigated, the conversion rate of ethylene is above 95%, the selectivity of ethylbenzene is >99%, and the content of xylene is less than 25ppm.

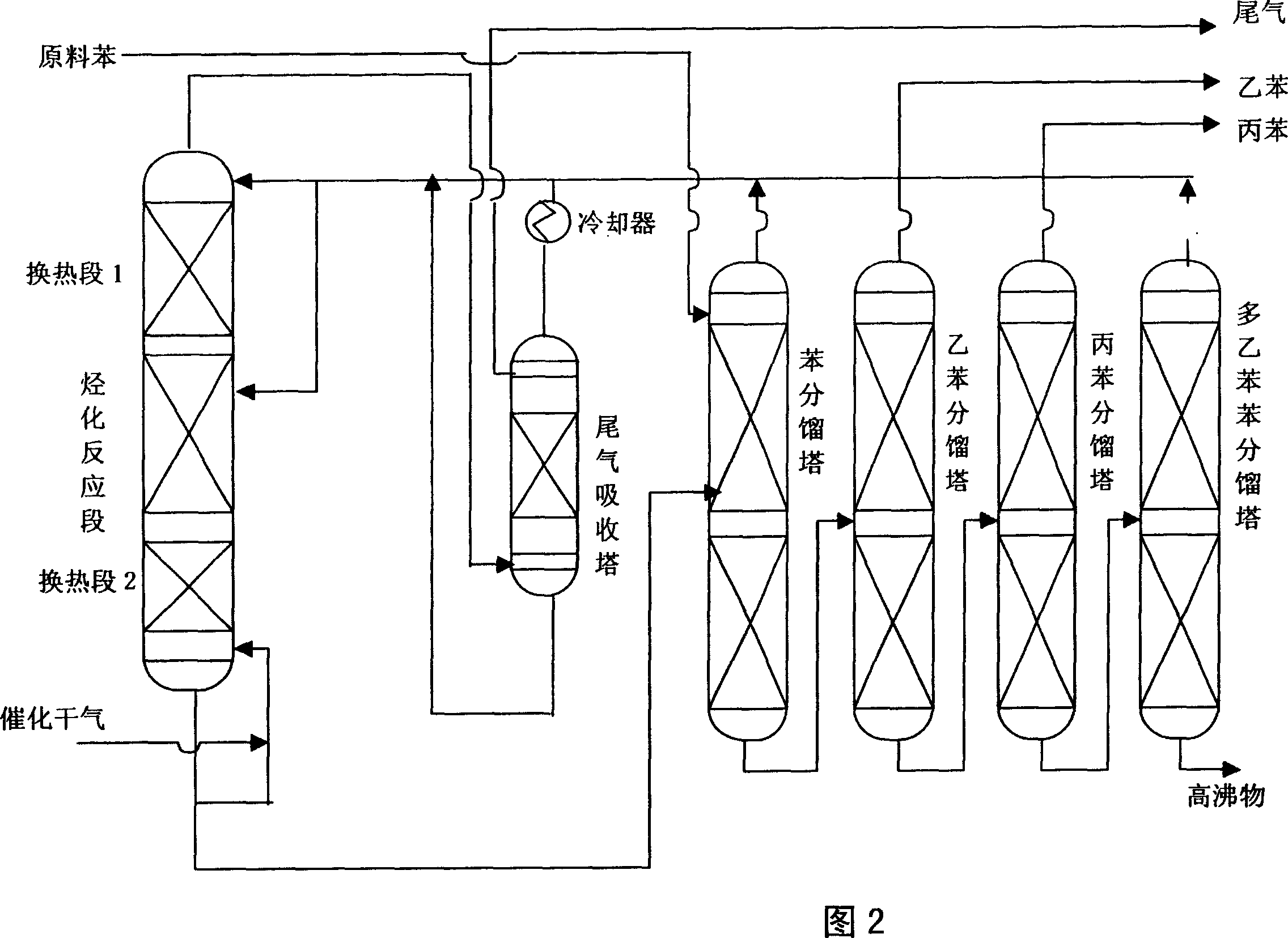

Embodiment 7

[0034] The process flow chart of the combination of catalytic dry gas, benzene phase-changing catalytic reaction and fractionation system of the present invention is shown in Figure 2. When the raw material gas contains less propylene, the propylene benzene separation tower may not be installed. According to the experimental results of the small test, the combined process can obtain the following results through simulation calculation: the conversion rate of ethylene is >95%, the selectivity of ethylene to ethylbenzene is >99%, the purity of ethylbenzene product is >99.8%, and the content of xylene in ethylbenzene is < 100ppm.

[0035] Reaction conditions

Reaction product distribution (%)

vinyl turn

Conversion rate (%)

Ethylbenzene True Selection

Selectivity (%)

Ethylbenzene list selection

Selectivity (%)

temperature

(℃)

pressure

(MPa)

Vinyl weight

Airspeed (h-1)

B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com