Hypothermia distillation device and method for separating stable isotopes

A low-temperature rectification and separation method technology, applied in the field of low-temperature rectification and separation equipment, can solve the problems such as the lack of application of low-temperature rectification tower adiabatic, and achieve the effects of increasing investment and technical difficulty, convenient operation and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

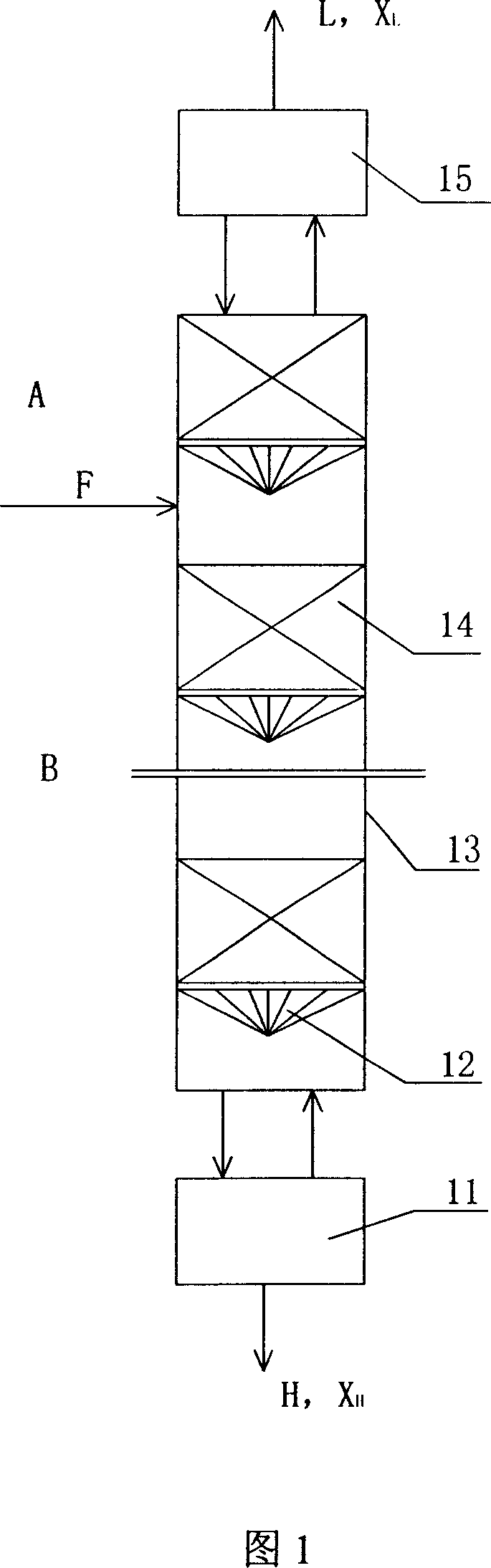

[0041] Example 1: CO cryogenic rectification separation of stable isotopes 13 C

[0042] As shown in Figure 1, the device is a low-temperature rectification device for separating stable isotopes with only one low-temperature rectification tower. The low-temperature rectification tower uses stainless steel wire mesh corrugated packing as structured packing, and the tower body is insulated with high-vacuum multi-layer insulation materials. The specific surface areas of the wire mesh corrugated packing are 500, 1000, and 1700m respectively. 2 / m 3 . The performance parameters are shown in Table 1. X shown in the table F is the heavy isotope abundance of raw gas, X L is the heavy isotope abundance of the light isotope product, X H is the heavy isotope abundance of the heavy isotope product.

[0043] Table 1.

Embodiment 2

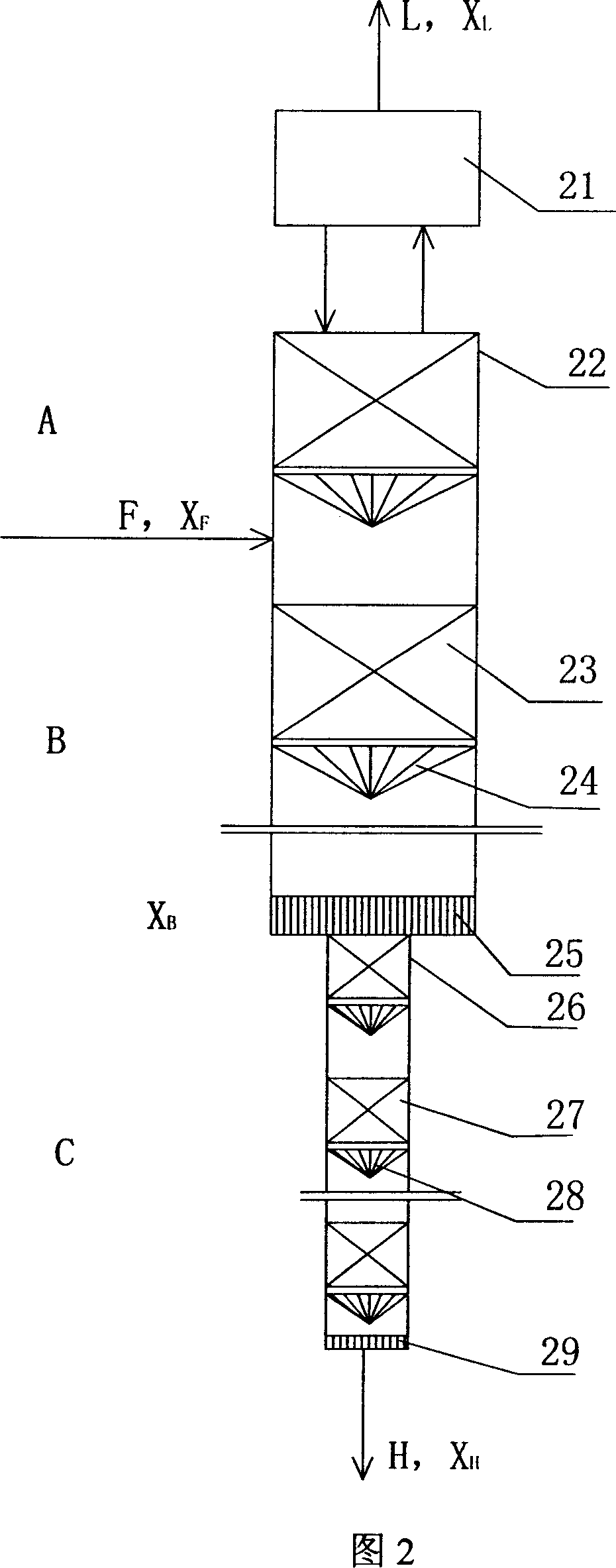

[0044] Example 2: Separation of Stable Isotopes by Two-column CO Low Temperature Rectification 13 C

[0045] As shown in Figure 2, the device is a low-temperature rectification device for separating stable isotopes comprising two low-temperature rectification towers (two-column cascade). The low-temperature rectification tower uses stainless steel wire mesh corrugated packing as the structured packing, and the tower body is insulated with high-vacuum multi-layer insulation materials. The diameters of the cascaded towers are 1m and 0.5mm respectively. The performance parameters are shown in Table 2. X shown in the table F is the heavy isotope abundance of raw gas, X L is the heavy isotope abundance of the light isotope product, X H is the heavy isotope abundance of the heavy isotope product, X B is the heavy isotope abundance at the bottom of the column in section B.

[0046] Table 2.

[0047] project

[0048] X F ,%

Embodiment 3

[0049] Example 3: NO cryogenic distillation and separation of stable isotopes 18 o

[0050] As shown in Figure 1, the device is a low-temperature rectification device for separating stable isotopes with only one low-temperature rectification tower. The low-temperature rectification tower adopts phosphor green steel wire mesh corrugated packing as structured packing, and the tower body is insulated with high-vacuum multi-layer insulation materials. The specific surface areas of the wire mesh corrugated packing are 500, 1000, and 1700m respectively 2 / m 3 . The performance parameters are shown in Table 3. X shown in the table F is the heavy isotope abundance of raw gas, X L is the heavy isotope abundance of the light isotope product, X H is the heavy isotope abundance of the heavy isotope product.

[0051] table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com