A high-precision combined multi-phase filtration and separation device

A filtration separation and combined technology, which is applied in the direction of filtration separation, filtration circuit, liquid separation, etc., can solve the problems of high cost of reclaimed water and sewage treatment equipment, poor separation ability and purity, and inconvenient replacement of filter elements, etc., to achieve clean production and circulation Economic utilization, solution to non-corrosion resistance, and the effect of reducing pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

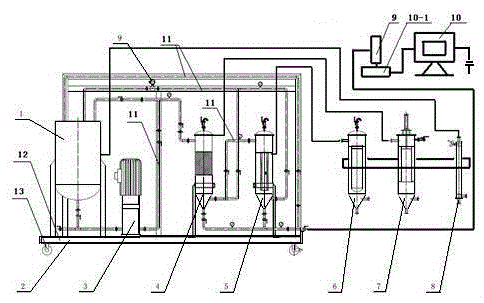

[0029] Example 1: Coalescing filter device 5 connects raw liquid tank 1 and frequency conversion centrifugal pump 3 with return pipe 11 as a group, plastic particle filter 7 connects oil mist separator 4 with return pipe 11 as a group, high corrosion resistance aluminum alloy filter The device 6 and the reclaimed water recovery treatment device 8 form a group, and the three groups of units are connected through the loop pipe 11 to form a combination of modular multi-unit integration. The modular design has a multi-unit integrated control data processor, and each group has Independent, plug-in program modules with different data settings, connected to the central processing unit by the sensor reader.

[0030] Step 1: Use the coalescing filter device to connect the oil mist separator with the return pipe as a group, the inclined corrugated plate separator and the plastic particle filter as a group, and the high corrosion resistance aluminum alloy filter and the reclaimed water ...

Embodiment 2

[0033] Example Two: The coalescing filter device is composed of a composite metal coalescing filter element and a filter element frame. The filter element frame is made of a stainless steel material with a thickness of 1.5mm punched by a special mold. The knotted filter element uses surface-treated glass fiber or polyester fiber as the coalescing medium, and then uses a winding machine to wind stainless steel fiber on the filter element frame, and multi-layer spiral winding according to the flow rate. The metal mesh on both sides of the oil mist separator And the filter set in the middle of the metal grid, the filter is fixed with 0.25mm stainless steel wire and the metal grid on both sides, and the filter is woven, rolled and laminated with ultra-fine glass fiber and stainless steel wire.

[0034] Since the inclined corrugated plate separator is connected to the plastic particle filter with a return pipe, it is a professional equipment for filtering plastic particles in diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com