Technology and equipment for recycling nitric oxides and purifying tail gas

A technology for nitrogen oxides and exhaust gas, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of difficult control and high energy consumption in the removal process of nitrogen oxides, achieve small footprint and improve conversion The effect of high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

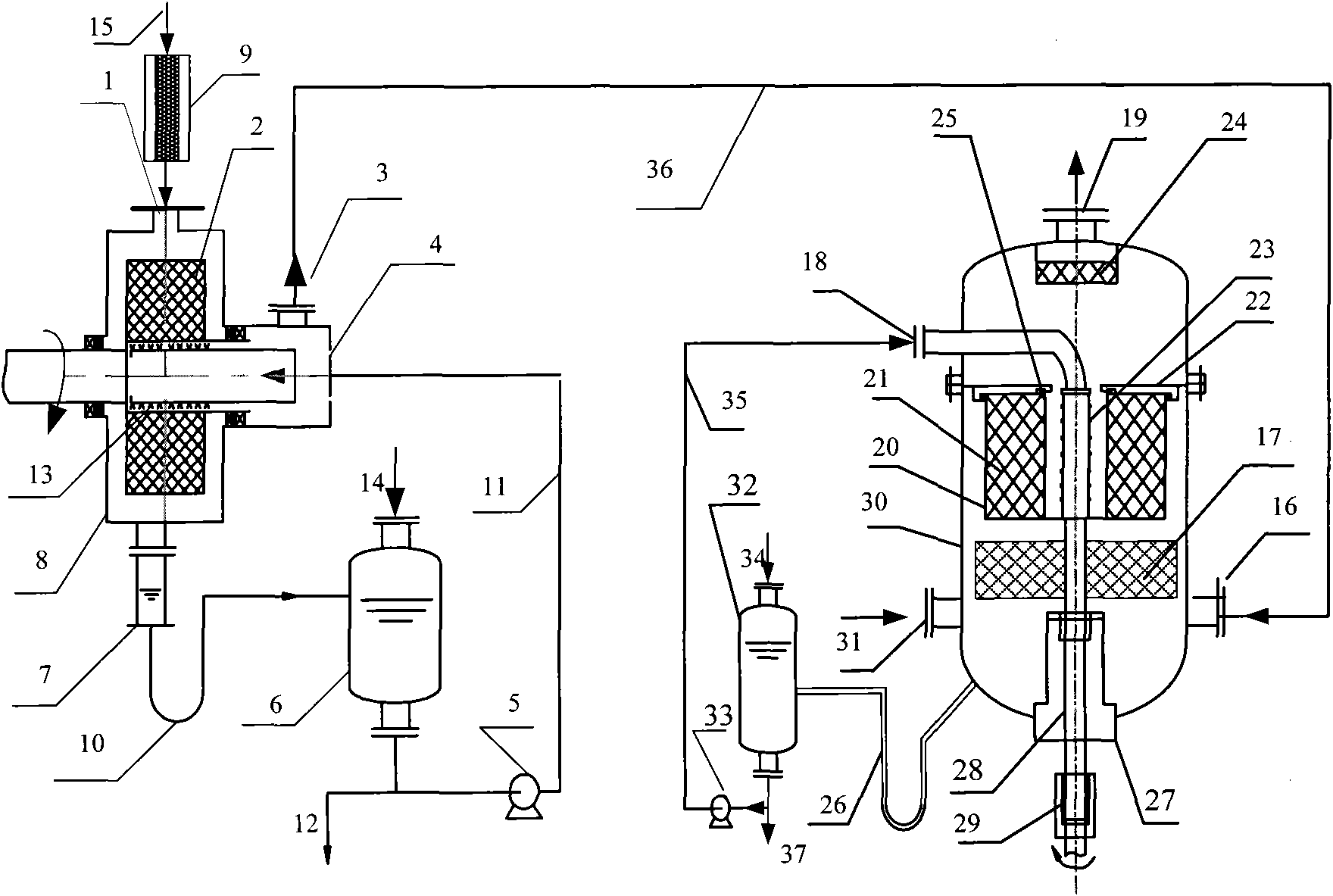

[0023] according to figure 1 As shown in the process, the gas volume of raw material gas A containing nitrogen oxides is 100m 3 / h, wherein, the concentration of NO is 10%v, the gas volume of oxygen (gas B) is 2m 3 / h, the nitrogen oxide-containing gas and the first stream of oxygen enter the pre-reactor 9 first, and react in advance at a high temperature to generate a mixed gas containing NO and NO2, and then the mixed gas and ethanol are separated from the first stage The gas inlet 1 of the rotating packed bed and the liquid inlet 4 of the first-stage rotating packed bed are introduced into the first-stage rotating packed bed 8 . Ethanol is placed in the first circulation tank 6, introduced into the first stage rotary packed bed liquid inlet 4 of the first stage rotary packed bed 8 by the first circulation pump 5 through the first stage rotary packed bed liquid circulation pipeline 11 and enters the second stage The first-stage rotating packed bed liquid distributor 13 and...

Embodiment 2

[0025] according to figure 1 Shown flow process, and the process of embodiment 1, only the gas amount that contains nitrogen oxide raw material gas A is 100m 3 / h, wherein, the concentration of NO is 20%v, the gas volume of oxygen (gas B) is 4m 3 / h, wherein, the temperature of prereactor 9 is 120 ℃, and the mol ratio of nitrogen oxides and ethanol liquid in the gas in the first-stage rotary packed bed 8 is 1: 20, and the rotating speed of the first-stage rotary packed bed is 2000rpm, and the reaction temperature 30°C, reaction pressure 0.01MPa, reaction temperature of the second-stage rotating packed bed is 30°C, pressure is 1 atm, volume ratio of liquid to gas is 1:30, second-stage rotating packed bed speed is 3000rpm, the result is: Nitrogen oxidation The material recovery rate is 99.21%, and the concentration of nitrogen oxides in the tail gas is 10ppm.

Embodiment 3

[0027] according to figure 1 Shown flow process, and the process of embodiment 1, only the gas amount that contains nitrogen oxide raw material gas A is 100m 3 / h, wherein, the concentration of NO is 15% v, the gas volume of oxygen (gas B) is 2.5m 3 / h, wherein, the temperature of prereactor 9 is 120 ℃, and the mol ratio of nitrogen oxides and ethanol liquid in the gas in the first-stage rotary packed bed 8 is 1: 10, and the rotating speed of the first-stage rotary packed bed is 4000rpm, and the reaction temperature 40°C, reaction pressure 0.3MPa, second stage rotary packed bed reaction temperature is 40°C, pressure is 0.1MPa, liquid to gas volume ratio is 1:100, second stage rotary packed bed speed is 5000rpm, the result is: nitrogen The recovery rate of oxides is 99.33%, and the concentration of nitrogen oxides in the tail gas is 2ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com