Method for preparing Fe3O4 from wastewater in chlorobenzene production

A waste water and chlorobenzene technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of difficult solid waste, unstable operation, inconvenient storage, etc., to reduce operating costs and labor Continuous and stable load and operation, avoiding time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

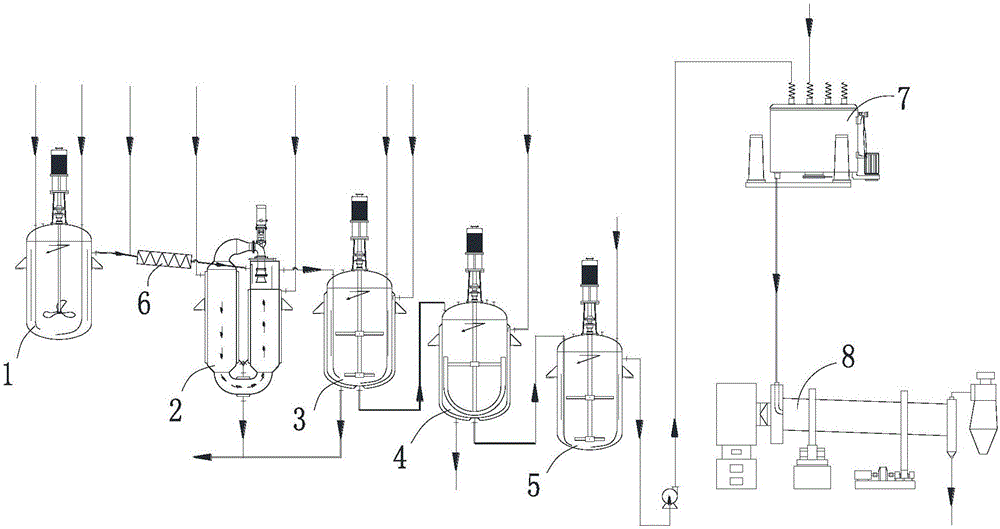

[0045] Such as figure 1 Shown:

[0046] A kind of waste water that is produced with chlorobenzene prepares Fe 3 o 4 method, including the following steps:

[0047] S1, pre-reaction: add washing waste water and Na to the first container 1 2 SO 3 Aqueous solution, the residence time is controlled at 0.75h, wherein, the first container 1 keeps stirring constantly;

[0048] S2. Pre-neutralization: add the first neutralization reagent to the solution in the first container 1 for pre-mixing, then transfer to the second container 2 filled with protective gas, maintain the temperature at 58°C, and stir until the solution pH=6 to obtain Solution A;

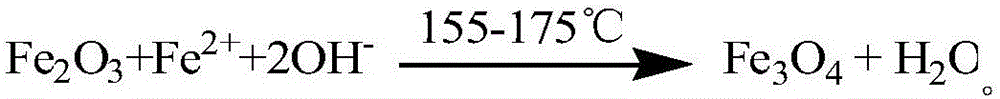

[0049]S3. Post-reaction: transfer the solution A in the second container 2 to the third container 3 filled with protective gas, maintain the temperature at 165° C., add the second neutralizing agent, and stir until the solution pH=12 to obtain the solution B;

[0050] S4. Aging: Transfer the solution B in the third container 3 to th...

Embodiment 2

[0054] Such as figure 1 Shown:

[0055] A kind of waste water that is produced with chlorobenzene prepares Fe 3 o 4 method, including the following steps:

[0056] S1. Pre-reaction: add washing wastewater and Na with a concentration of 2mol / L to the first container 1 2 SO 3 Aqueous solution, the residence time is controlled at 0.5h, wherein, the first container 1 keeps stirring constantly, SO 3 2- and Fe in washing wastewater 3+ The molar ratio is 2.5:1;

[0057] S2. Pre-neutralization: add the first neutralization reagent to the solution in the first container 1 and pre-mix with the static mixer 6, then transfer to the second container 2 filled with nitrogen, maintain the temperature at 50°C, and stir until the solution pH=7.5 obtains solution A, wherein, the first neutralization reagent is that the mass fraction is 5wt% sodium hydroxide aqueous solution, the second container 2 is U-shaped, and the flow rate of nitrogen is 5m 3 / h;

[0058] S3. Post-reaction: Transf...

Embodiment 3

[0063] Such as figure 1 Shown:

[0064] A kind of waste water that is produced with chlorobenzene prepares Fe 3 o 4 method, including the following steps:

[0065] S1. Pre-reaction: add washing wastewater and Na with a concentration of 3mol / L to the first container 1 2 SO 3 Aqueous solution, the residence time is controlled at 1h, wherein, the first container 1 keeps stirring constantly, SO 3 2- and Fe in washing wastewater 3+ The molar ratio is 1.5:1;

[0066] S2. Pre-neutralization: add the first neutralization reagent to the solution in the first container 1 and pre-mix with a static mixer 6, then transfer to the second container 2 filled with nitrogen, maintain the temperature at 65 ° C, and stir until the solution pH=2.2 obtains solution A, wherein, the first neutralization reagent is in the waste lye, the second container 2 is U-shaped, and the flow rate of nitrogen is 10m 3 / h;

[0067] S3. Post-reaction: Transfer the solution A in the second container 2 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com