Device for polytetrafluoroethylene film hardening and thermal recombining

A technology of polytetrafluoroethylene and curing device, which is applied in the direction of lamination device, chemical instrument and method, application, etc., and can solve the problems of polytetrafluoroethylene film melting, lack of high-temperature adhesive, and difficulty in processing composite filter materials , to achieve the effect of improving uniformity, avoiding environmental pollution, and overcoming high temperature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

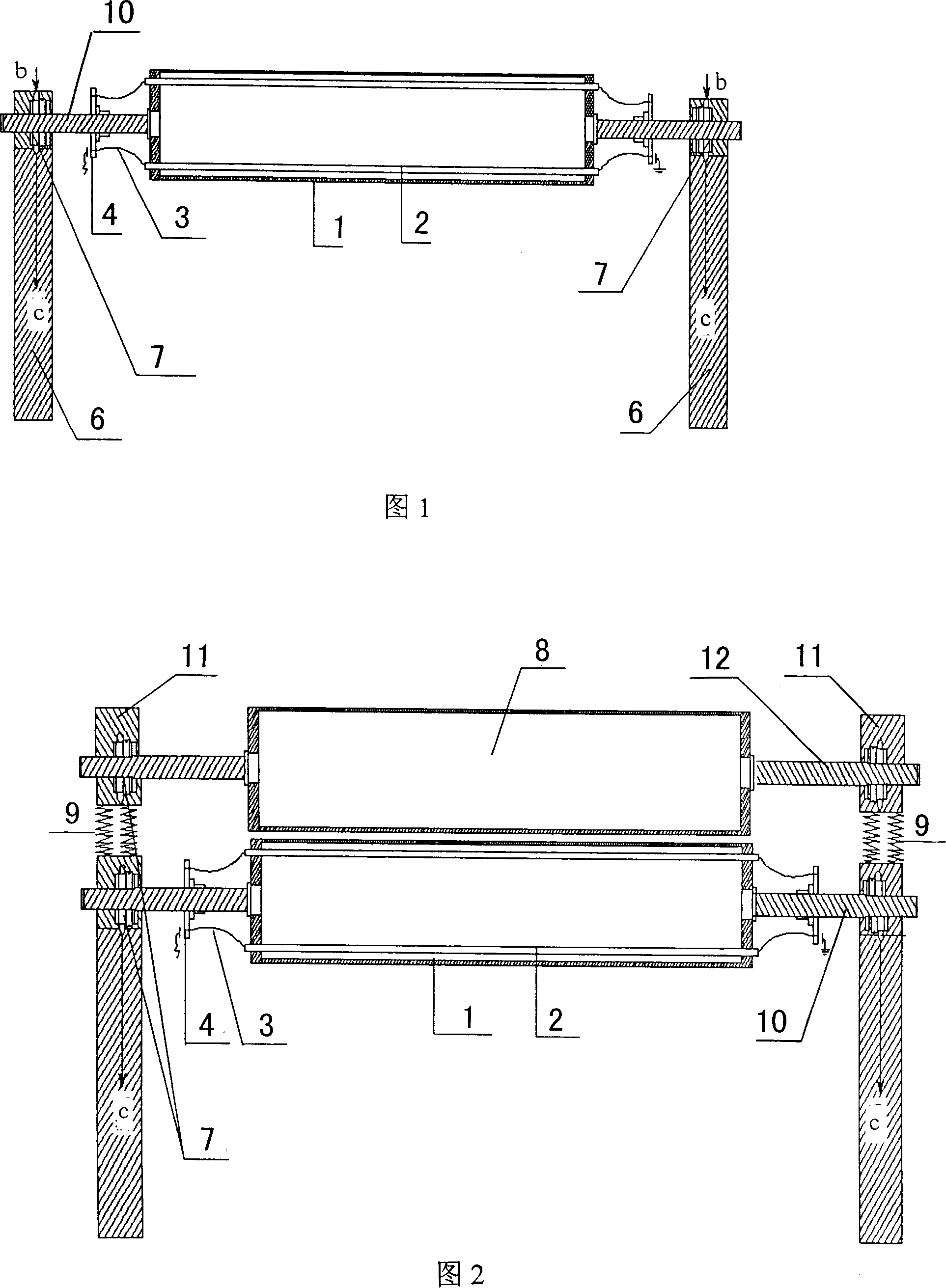

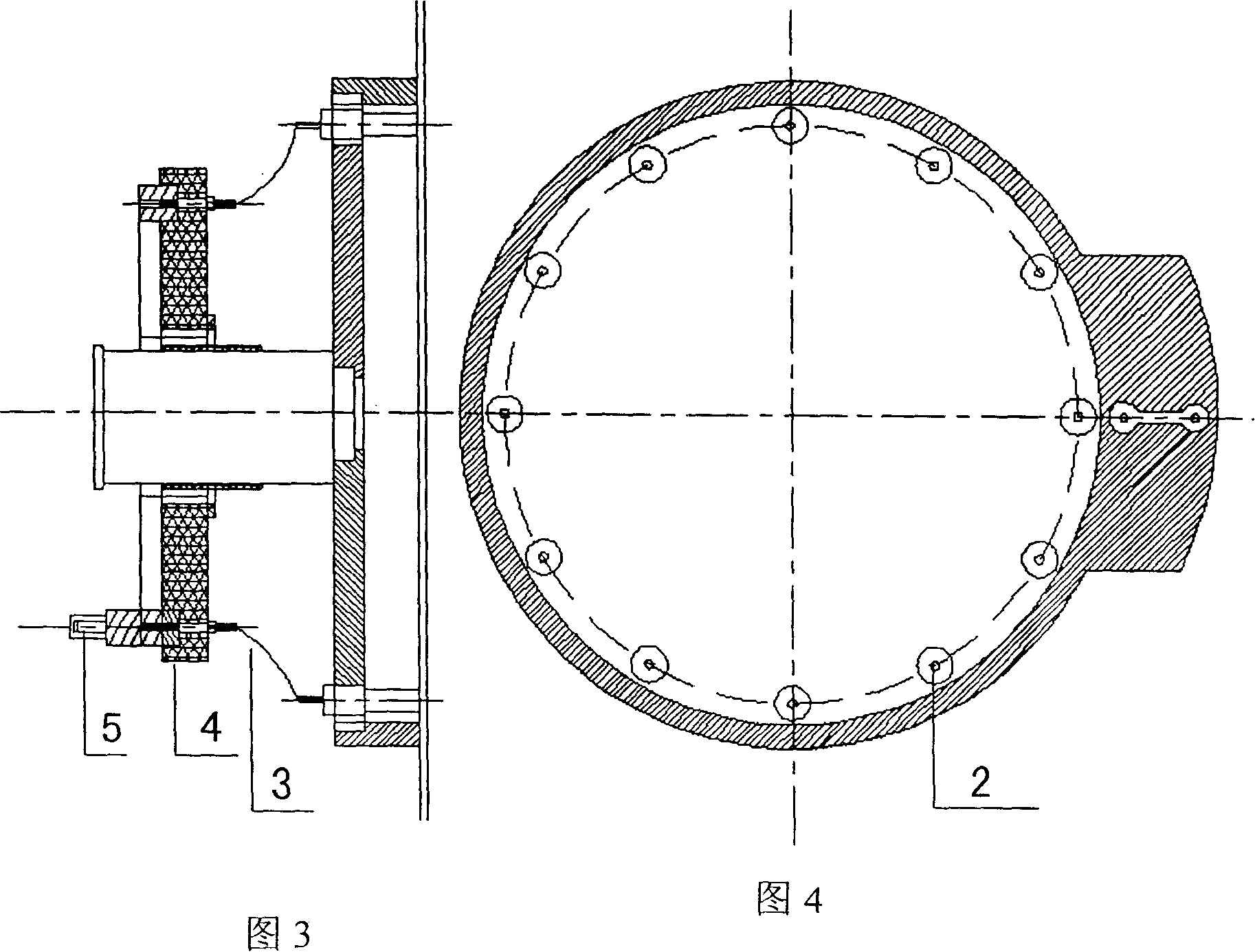

[0023] Refer to Fig. 1, Fig. 3 and Fig. 4 for the device used for curing polytetrafluoroethylene film. The device for curing polytetrafluoroethylene film has a hot roller 1, the wall thickness of the hot roller 1 is 5 mm, the outer diameter is 300 mm, and the material is nickel-based alloy steel. It is heated by 12 electric heating tubes 2 placed inside the heat roller 1. The electric heating tubes are equally packed on the same circumference inside the heating roller 1, and one end of the electric heating tubes is connected with the conductive plate 4 by a wire 3, and all the electric heating tubes 2 are connected in parallel, one end is connected to the positive pole of the power supply, and the other end Connect the negative pole of the power supply. The heat roller 1 rotates synchronously with the conductive disk 4, and the two conductive disks 4 are respectively installed on the rotating shafts 10 on both sides. The conductive disk is provided with a friction conductive ...

Embodiment 2

[0026] Refer to Fig. 1, Fig. 3 and Fig. 4 for the device used for curing polytetrafluoroethylene film. The device for curing polytetrafluoroethylene film has a hot roller 1, the wall thickness of the hot roller 1 is 15 mm, the outer diameter is 450 mm, and the material is nickel-based alloy steel. It is heated by 20 electric heating tubes 2 placed inside the heat roller 1. The electric heating tubes 2 are equally packed on the same circumference inside the heat roller 1, and one end of the electric heating tubes is connected to the conductive disk 4 by a wire 3, all the electric heating tubes 2 are connected in parallel, one end is connected to the positive pole of the power supply, and the other is Connect one end to the negative pole of the power supply. The heat roller 1 rotates synchronously with the conductive disk 4, and the two conductive disks 4 are respectively installed on the rotating shafts 10 on both sides. The conductive disk is provided with a friction conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com