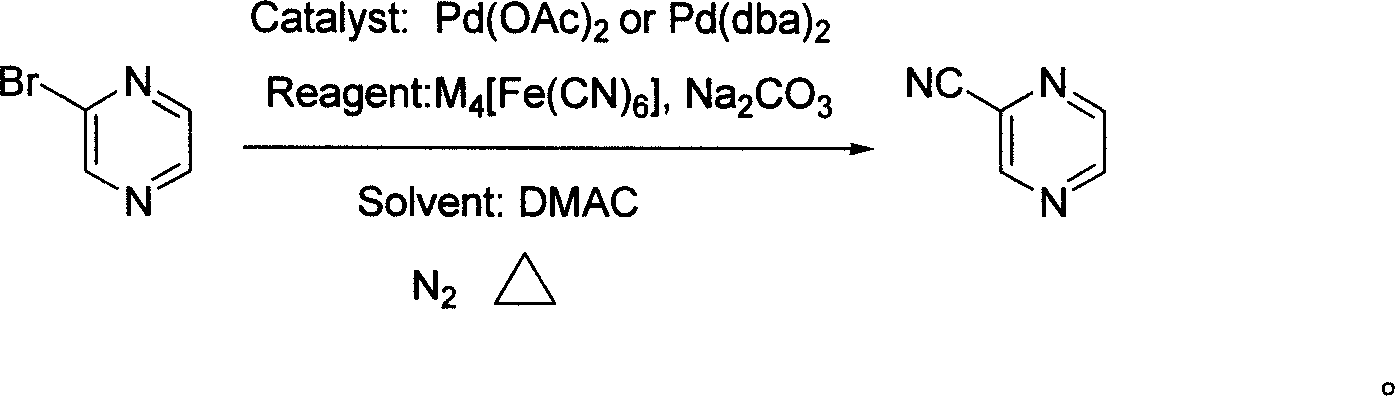

Preparation process of intermediate 2-cyanpyrazine of pyrazinamide drug

A technology of pyrazinamide and cyanopyrazine, applied in the direction of organic chemistry, etc., can solve the problems of harsh conditions, high temperature and high pressure conditions, complicated post-processing, etc., and achieve the effect of simple feeding and post-processing, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a 1000 ml three-necked flask, 500 ml of N,N-dimethylacetamide solvent, 48 g (300 mmol) of 2-bromopyrazine, 25 g (60 mmol, 0.2 equivalents) of tris Potassium ferrocyanide hydrate, 680 milligrams (3 millimoles, 0.3mol%) palladium acetate catalyst, 35 grams of sodium carbonate (330 millimoles, 1.1 equivalents), under nitrogen protection at 120 ℃ stirring reaction 2 hours, finish reaction, Then filtered, the filtrate was fractionated under reduced pressure to obtain transparent liquid 2-cyanopyrazine, boiling point: 84-87°C (18-20mmHg), yield 88%, purity 98% (GC).

Embodiment 2

[0020] In a 1000 ml three-necked flask, 500 ml of N,N-dimethylacetamide solvent, 48 g (300 mmol) of 2-bromopyrazine, 28 g (66 mmol, 0.22 equivalent) of tris Potassium ferrocyanide hydrate, 340 milligrams (15 millimoles, 5mol%) palladium acetate catalyst, 31.8 gram sodium carbonates (300 millimoles, 1.0 equivalents), under nitrogen protection, stirred reaction at 100 ℃ for 13 hours, ended the reaction, then After filtration, the filtrate was fractionated under reduced pressure to obtain transparent liquid 2-cyanopyrazine with a yield of 90% and a purity of 99%.

Embodiment 3

[0022] In a 1000 ml three-necked flask, 500 ml of N,N-dimethylacetamide solvent, 48 g (300 mmol) of 2-bromopyrazine, 20 g (45 mmol, 0.15 equivalent) of tris Sodium ferrocyanide hydrate, 1.5 millimoles (0.5mol%) two (dibenzylidene pyruvate) palladium catalysts, 31.8 grams of sodium carbonate (300 millimoles, 1.0 equivalent), under nitrogen protection, at 120 ℃ stirring reaction 4 Hours, the reaction was terminated, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain a transparent liquid 2-cyanopyrazine with a yield of 80% and a purity of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com