A method for microwave sintering zinc oxide pressure-sensitive resistor

A varistor, microwave sintering technology, applied in the direction of varistor, varistor core, resistor, etc., can solve the problems of affecting varistor ceramic components, long sintering time, energy waste, etc., to improve product quality. Performance, short sintering time, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: Microwave sintering low voltage zinc oxide varistor

[0081] Follow the steps below to implement:

[0082] a. According to the formula shown in Table 2, the various raw materials are accurately weighed and proportioned, and the traditional manufacturing process is used to ball mill, spray granulate, and press into a low-voltage varistor green body with a specification of 20×1.5mm, and then use the traditional process to discharge glue.

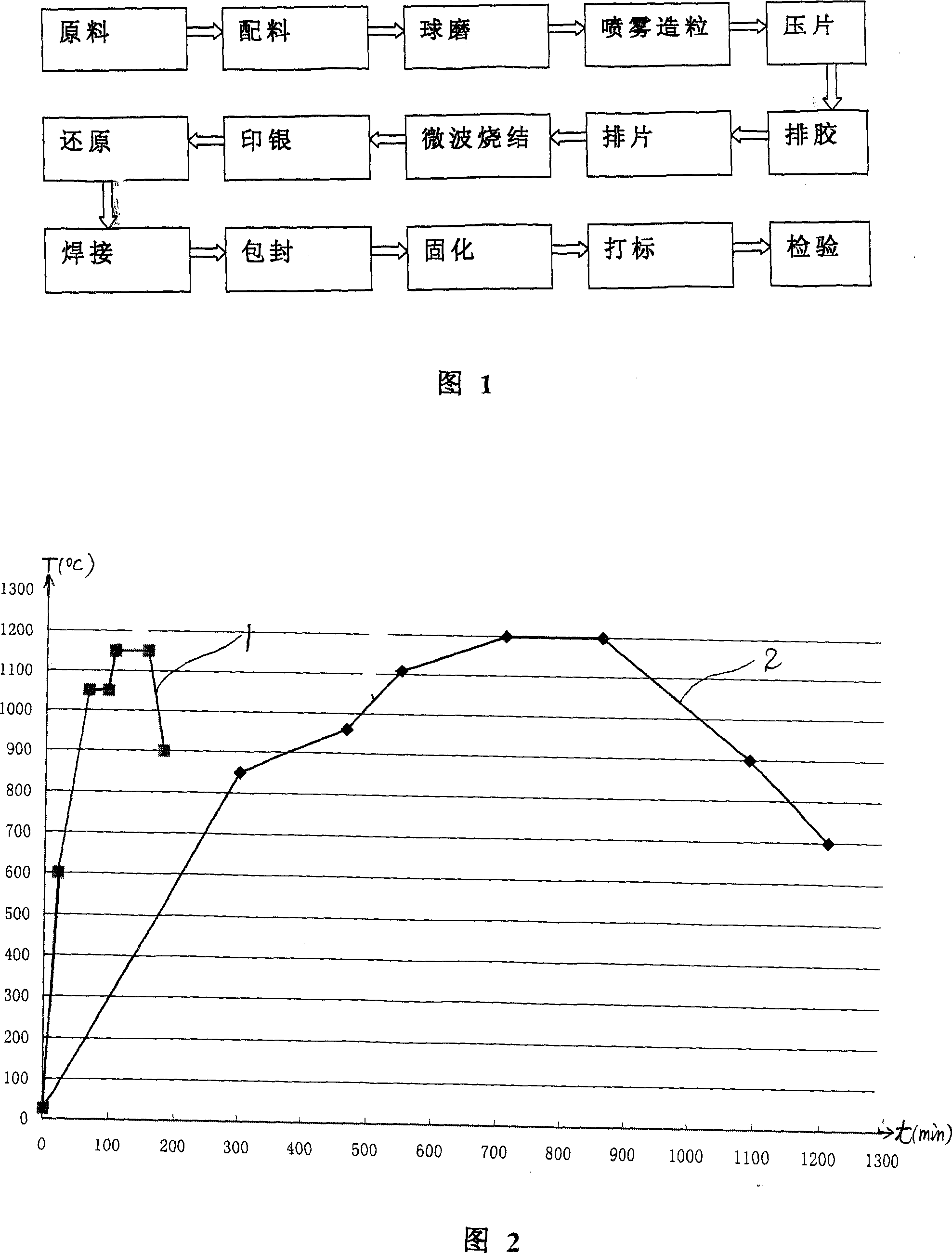

[0083] b. Neatly arrange the degummed green sheets in a certain way in a sintering bowl with mullite as the main raw material, and the number of stacked layers is less than 20. The sintering bowl is sealed and put into the furnace cavity of the microwave sintering furnace, and the cavity wall of the furnace cavity is composed of oxide ceramics or oxide ceramic fibers. 1 represents the microwave sintering temperature curve among the accompanying drawing 2, controls the cavity temperature of the microwave sintering furnace b...

Embodiment 2

[0099] Example 2: Microwave sintering medium and high voltage varistors

[0100] Follow the steps below to implement:

[0101] a. According to the formula shown in Table 4, the various raw materials are accurately weighed and proportioned, and the traditional manufacturing process is used to ball mill, spray granulate, and press into a medium and high voltage varistor green body with a specification of 24×1.2mm, and then use the traditional process Degumming.

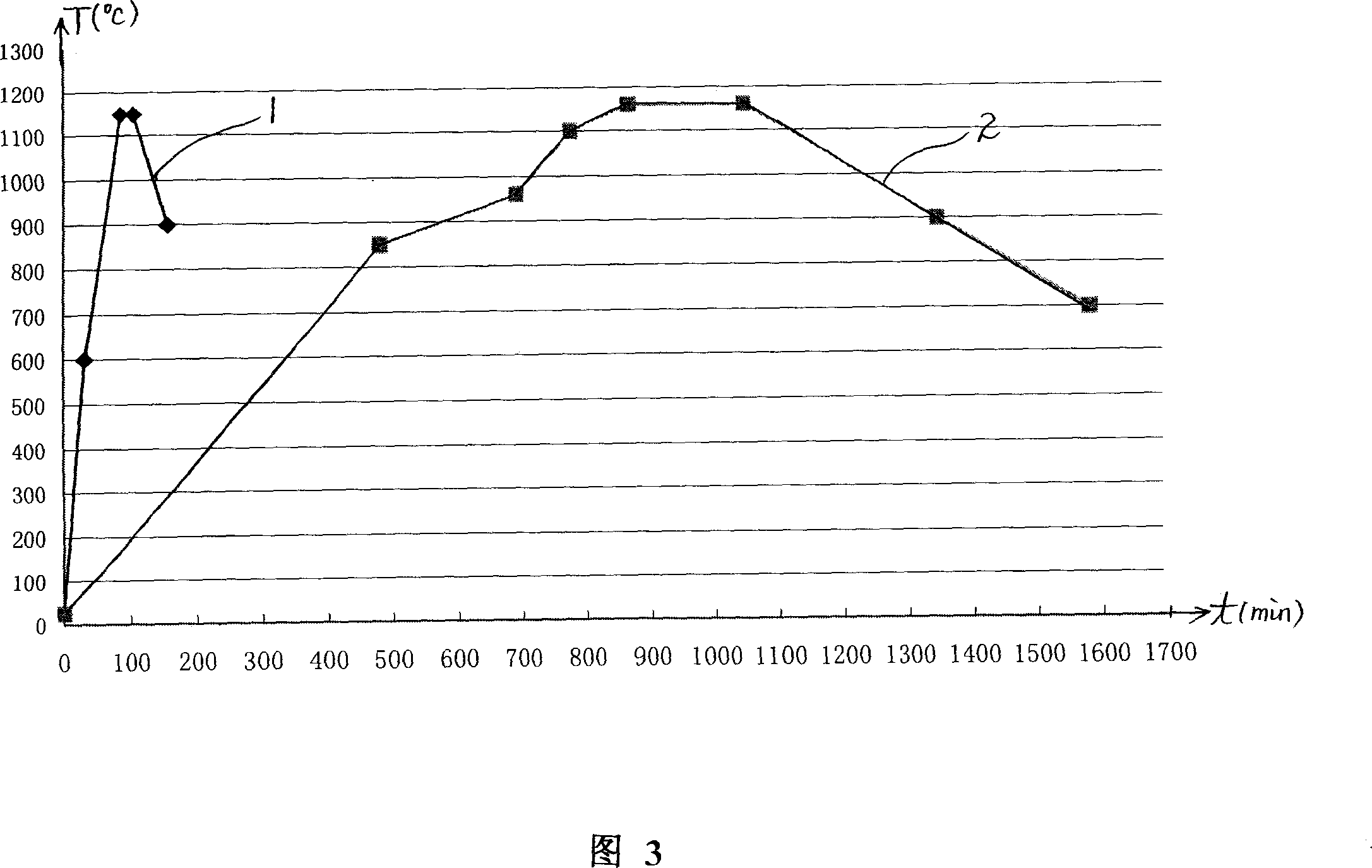

[0102] b. Neatly arrange the degummed green sheets in a certain way in a sintering bowl with mullite as the main raw material, and the number of stacked layers is less than 20. The sintering bowl is sealed and put into the furnace cavity of the microwave sintering furnace, and the cavity wall of the furnace cavity is composed of oxide ceramics or oxide ceramic fibers. 1 represents the microwave sintering temperature curve among the accompanying drawings 3, controls the cavity temperature of the microwave sintering fu...

Embodiment 3

[0118] Example 3: Microwave sintering high-energy low-field-strength zinc oxide varistor valve sheet

[0119] Follow the steps below to implement:

[0120] a. Accurately weigh and proportion various raw materials according to the formula shown in Table 6, ball mill, spray granulate, and press into a varistor valve green body with a specification of 105×20mm by traditional manufacturing techniques, and then use traditional Process degumming.

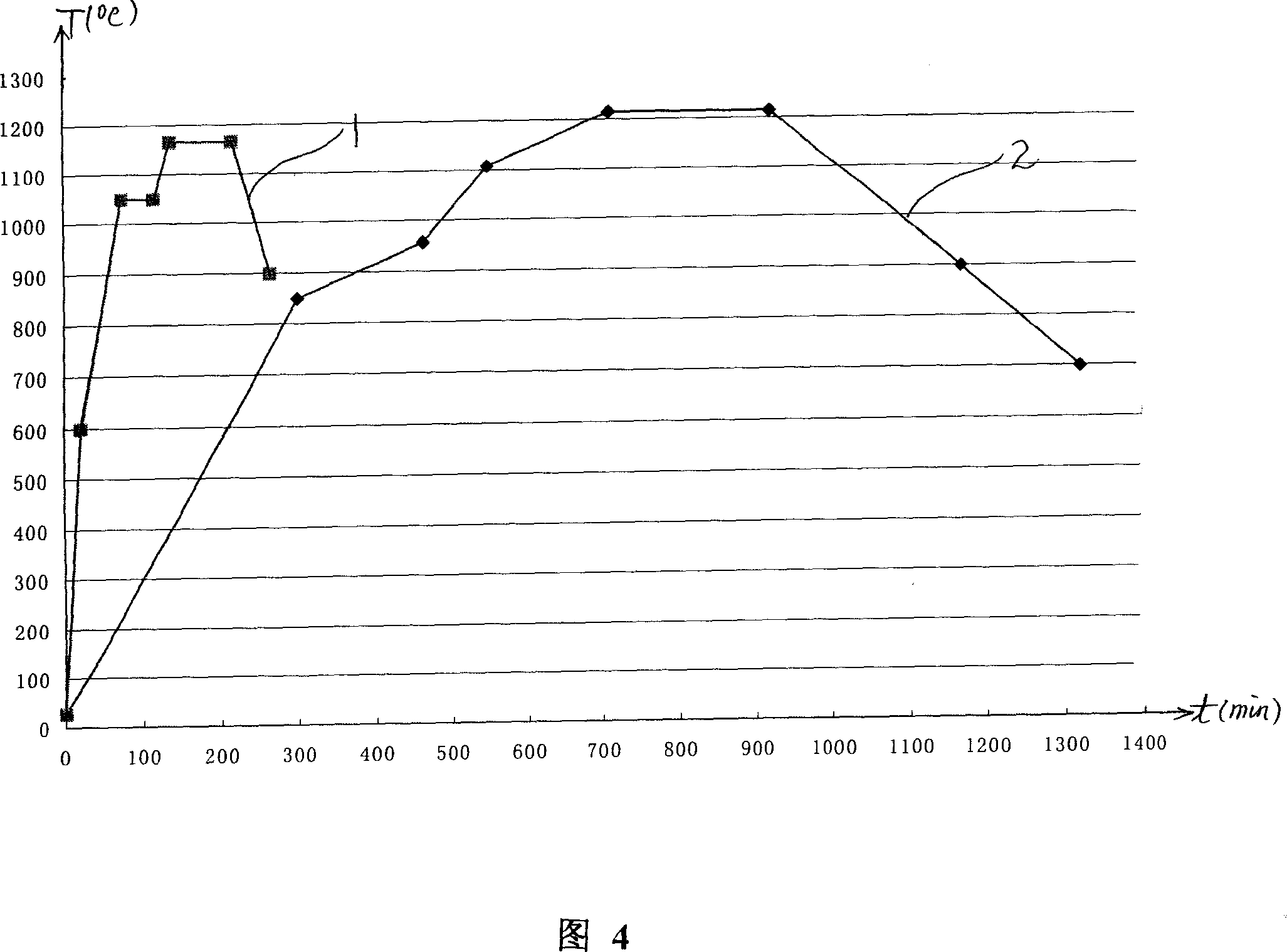

[0121] b. Neatly arrange the degummed green sheets in a certain way in a sintering bowl with mullite as the main raw material, and the number of stacked layers is less than 20. The sintering bowl is sealed and put into the furnace cavity of the microwave sintering furnace, and the cavity wall of the furnace cavity is composed of oxide ceramics or oxide ceramic fibers. 1 represents the microwave sintering temperature curve among the accompanying drawing 4, controls the cavity temperature of the microwave sintering furnace by the microwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com