Electrode and membrane electrode of proton exchange membrane fuel cell, and making method and application

A proton exchange membrane and fuel cell technology, which is applied in fuel cell parts, fuel cells, battery electrodes, etc., can solve problems that have not yet been reported, and achieve the effect of reducing gas mass transfer resistance and increasing porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] a. Preparation of membrane covered with catalyst layer

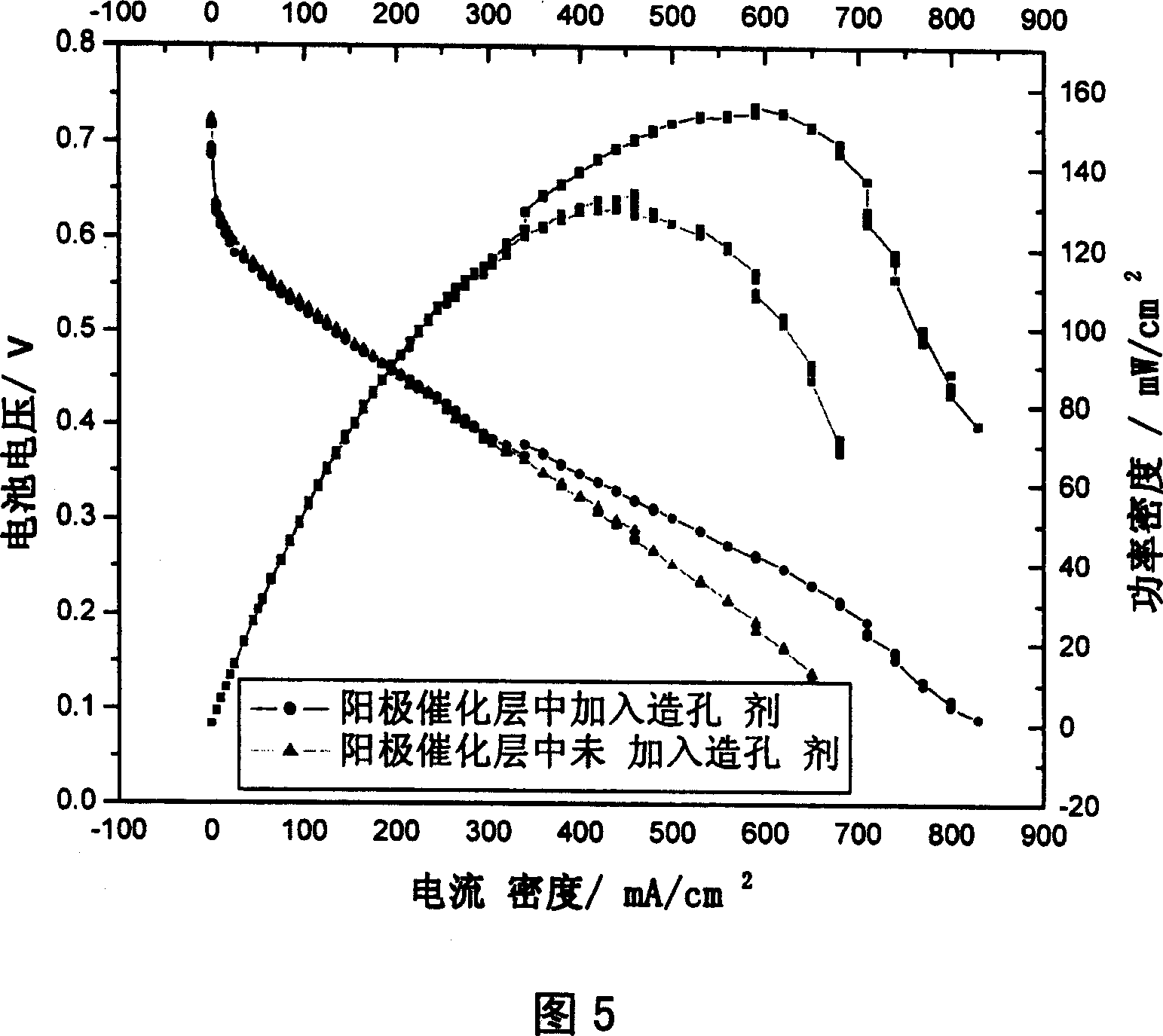

[0042] 1) Prepare the anode catalyst slurry, weigh 96mg of PtRu black (Johnson Matthey), then add 1920mg of a mixed solvent of absolute ethanol and water (water: absolute ethanol = 1:20 mass ratio), mix well and then add 338mg of 5% Nafion ( Dupont, EW value is 1100) solution, use spray gun to spray this slurry on one side of the Nafion 115 film of Na type evenly, the loading capacity of catalyst is 3.2mg / cm 2 .

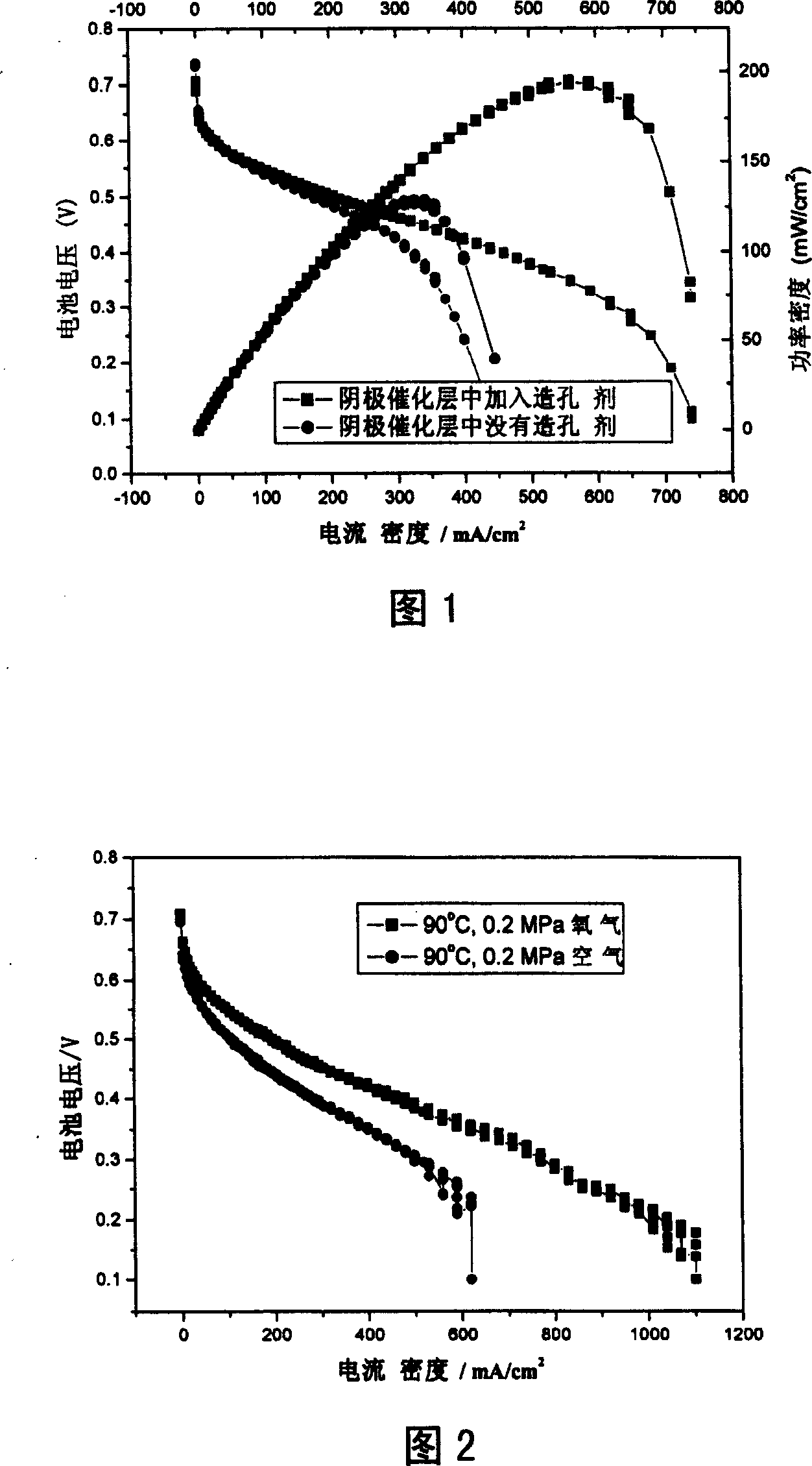

[0043] 2) Configure the cathode catalyst slurry in the same way, add 1500mg of absolute ethanol and water mixed solvent (water: absolute ethanol = 1:20 mass ratio) to 50mg Pt black (Johnson Matthey), then add 112mg of 5% Nafion solution, 100mg of ammonium carbonate (5% aqueous solution), stir and mix uniformly to obtain catalyst slurry, and use a spray gun to spray this slurry evenly on the other side of the Nafion 115 film of Na type. The loading amount of the catalyst is 2.3mg / cm 2 .

[0044] 3) Trea...

Embodiment 2

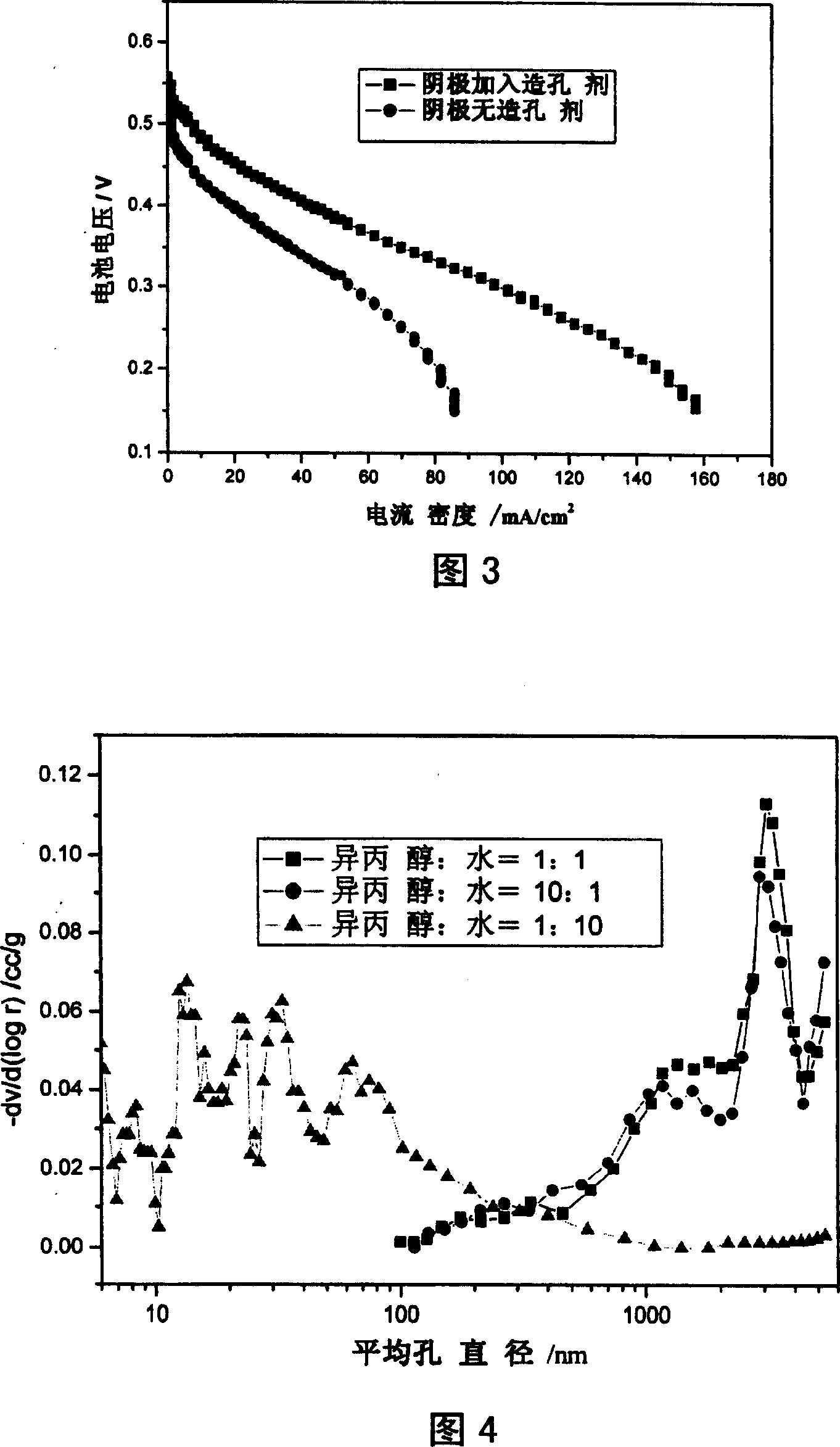

[0049] Prepare slurry according to embodiment 1 step, then catalyst slurry is sprayed on PTFE film, and catalyst slurry composition is respectively: anode: adopt PtRu black (Johnson Matthey) catalyst, 3.2mg / cm 2 , a mixed solvent of isopropanol and water (water: isopropanol=1:5) is used as a dispersant, the mass ratio of the dispersant to the catalyst is 30:1, and the mass ratio of Nafion to the catalyst is 3:17. Cathode: using carbon-supported catalyst, the carbon support is BP-2000, the loading of Pt is 40wt%, 3.0mg / cm 2 , the mixed solvent of Virahol and water (water: Virahol=1: 2) as dispersant, the mass ratio of dispersant and catalyst is 30: 1, Nafion and catalyst mass ratio 3: 17, ammonium oxalate (with Nafion mass ratio The ratio is 1:1), NaOH (the mass ratio to Nafion is 1:1). Put the cathode catalytic layer at 180°C N 2 Treated under gas protection conditions for 3 hours. Cut out the PTFE membrane prepared above, the size is 2×2cm 2 , placed on both sides of the ...

Embodiment 3

[0054] CCM was prepared according to the steps in Example 1, and the proton exchange membrane was H-type Nafion115. Electrode loads are: anode, PtRu black (Johnson Matthey), 3.6mg / cm 2 , the mass ratio of Nafion to catalyst is 3:17. Cathode: Pd 3 Pt 1 / C (the atomic ratio of Pd to Pt is 3:1), 2.5mg / cm 2 , Nafion and catalyst mass ratio 1: 9, lithium carbonate (1: 1 with Nafion mass ratio). The thickness of the cathode prepared by this method is about 20 μm, and the porosity can reach 50%.

[0055] For the convenience of comparison, the preparation of CCM is as follows: the other conditions of the anode and cathode are the same as above, except that no pore-forming agent is added to the cathode catalyst.

[0056] The performance of the membrane electrode under air self-breathing conditions at 60°C is shown in Figure 3. Operating conditions: 1M methanol aqueous solution 0.25ml / min sample injection; the cathode is air self-breathing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com