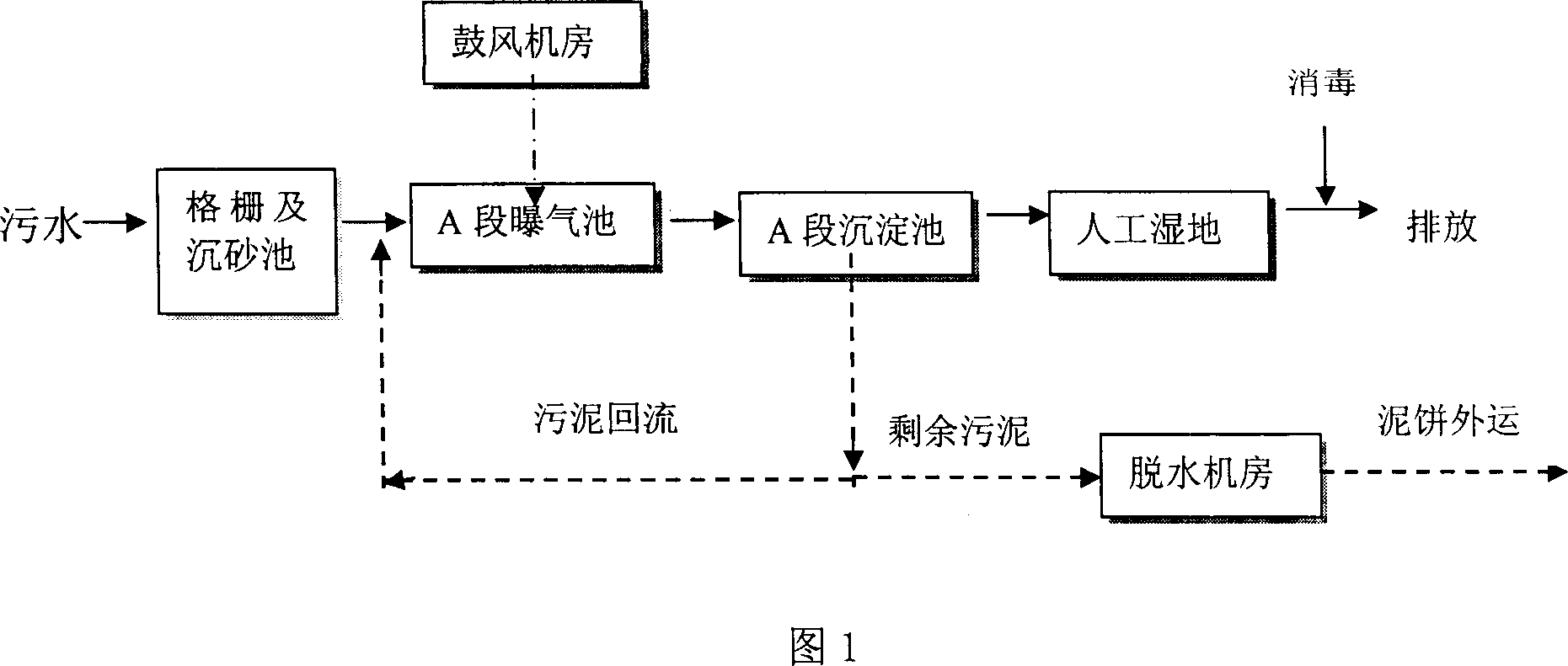

Biological adsorption and artificial wetland combined town sewage treatment system and method

A constructed wetland and biological adsorption technology, applied in the fields of adsorbed water/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. The reproduction speed is fast, the sludge settling performance is good, and the effect of solving the large area is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The sewage treatment scale of this embodiment is 20,000 m 3 / d, the influent is domestic sewage in cities and towns.

[0032] The sewage treatment method of the present embodiment comprises the following steps:

[0033] 1) The sewage to be treated is firstly pretreated by coarse and fine grids and grit chambers to remove floating matter and fine sand particles in the sewage (thick and fine grids and grit chambers are conventional equipment for water treatment);

[0034] 2) Then the water enters the A section aeration tank of the A section biosorption unit of the AB process, removes suspended particles (SS) and organic matter (BOD) in the water, and simultaneously removes nitrogen and phosphorus; the A section aeration of the present embodiment The parameters used in the pool are: hydraulic retention time 30min, sludge load 6.0kgBOD 5 / kgMLSS·d, dissolved oxygen is 0.5mg / l;

[0035] 3) The sewage continues to pass through the A section sedimentation tank of the A sect...

Embodiment 2

[0040] The sewage treatment scale of this embodiment is 8000m 3 / d, the influent is domestic sewage and industrial wastewater, and industrial wastewater accounts for about 20% of the total sewage.

[0041] The sewage treatment method of the present embodiment comprises the following steps:

[0042] 1) The sewage to be treated first passes through the coarse and fine grids and the grit chamber to remove the floating matter and fine sand particles in the sewage;

[0043] 2) Then the water enters the A section of the AB process, that is, the A section aeration tank of the biosorption unit, and removes suspended particles (SS) and organic matter (BOD) in the water. The parameters used in the A section aeration tank of the present embodiment are : Hydraulic retention time 40min, sludge load 4.0kgBOD 5 / kgMLSS·d, dissolved oxygen is 1.5mg / l;

[0044] 3) The sewage continues to pass through the sedimentation tank of the A section of the A section of the AB process, so that the flo...

Embodiment 3

[0048] Sewage treatment scale is 6000m 3 / d, the influent is domestic sewage.

[0049] The sewage treatment method of the present embodiment comprises the following steps:

[0050] 1) The sewage to be treated is firstly pretreated through the coarse and fine grids and the grit chamber to remove the floating matter and fine sand particles in the sewage;

[0051] 2) Then the water enters the A section aeration tank of the A section biosorption unit of the AB process, removes suspended particles (SS) and organic matter (BOD) in the water, and simultaneously removes nitrogen and phosphorus; the A section aeration of the present embodiment The design parameters adopted by the tank are hydraulic retention time 50min, sludge load 4.5kgBOD 5 / kgMLSS·d, dissolved oxygen is 1.2mg / l;

[0052] 3) The sewage continues to pass through the sedimentation tank of the A section of the A section of the AB process, so that the flocculent activated sludge and inorganic suspended particles in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com