High-strength steel mesh for use in concrete and its making method

A technology of high-strength steel wire and production method, which is applied in the field of high-strength steel wire mesh, can solve the problems of prolonging the construction period of the project, increasing the cost of the project, and waste of steel materials, so as to achieve high joint shear resistance, reduce steel consumption, and reduce engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

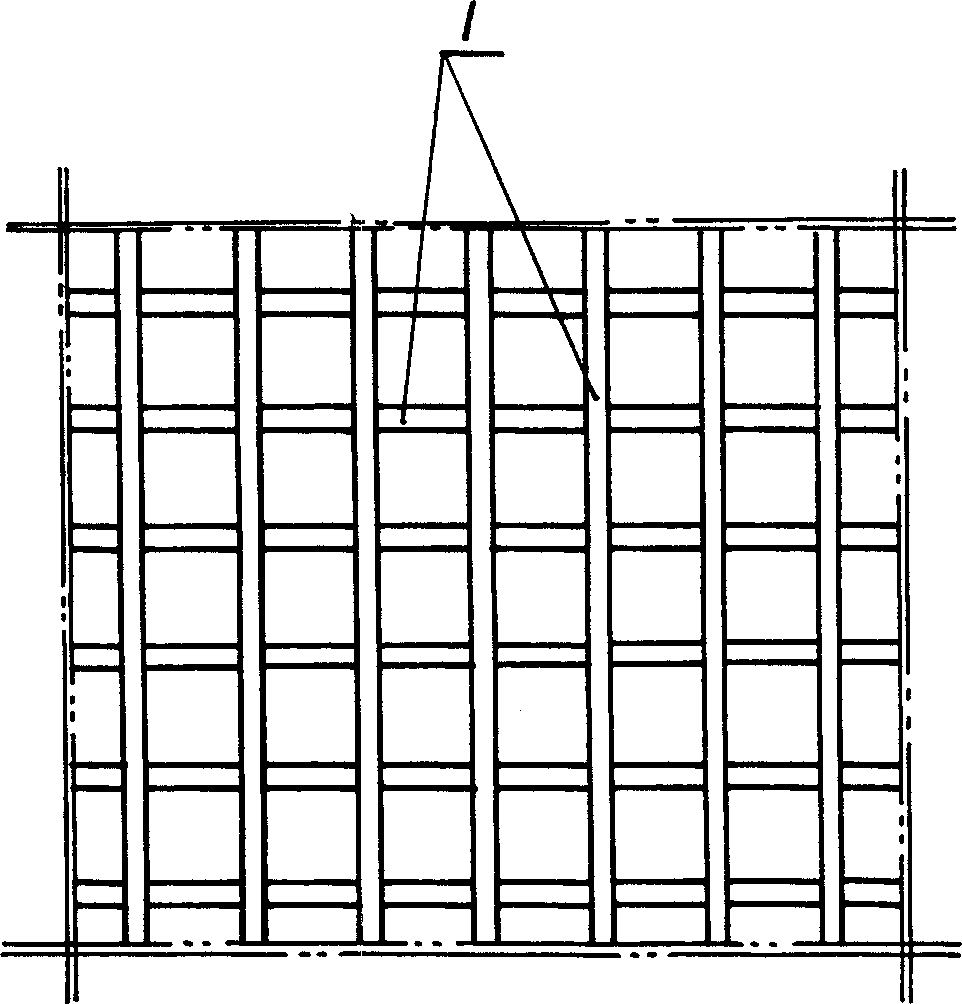

[0013] In the present invention, multiple high-strength high-carbon steel wires 1 are crossed vertically and horizontally to form a grid, and are welded into a whole at the junction according to the three-step method of preheating-welding-tempering.

[0014] The high-carbon steel wire 1 is a carbon steel wire with a carbon content ≥ 0.60% in the material, such as spring steel wire, prestressed steel wire, etc.; the high-carbon steel wire can be smooth steel wire, spiral rib steel wire or scored steel wire.

[0015] The accompanying drawing is an embodiment of the present invention. The high-carbon steel wire 1 of this embodiment adopts a high-carbon steel wire with a carbon content of 0.70%, a diameter of 3 mm, a clean surface, and straightening.

[0016] A plurality of high-carbon steel wires 1 are arranged vertically and horizontally in two directions to form a grid, and preheated to 200-300°C; then, the high-carbon steel wires at the intersection points of the grid are welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com