Method for preparing active red DF-3BS

A technology of DF-3BS and activity, which is applied in the field of preparation of reactive red DF-3BS, can solve the problems of increasing costs, and achieve the effects of reducing raw material costs, excellent color giving power, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

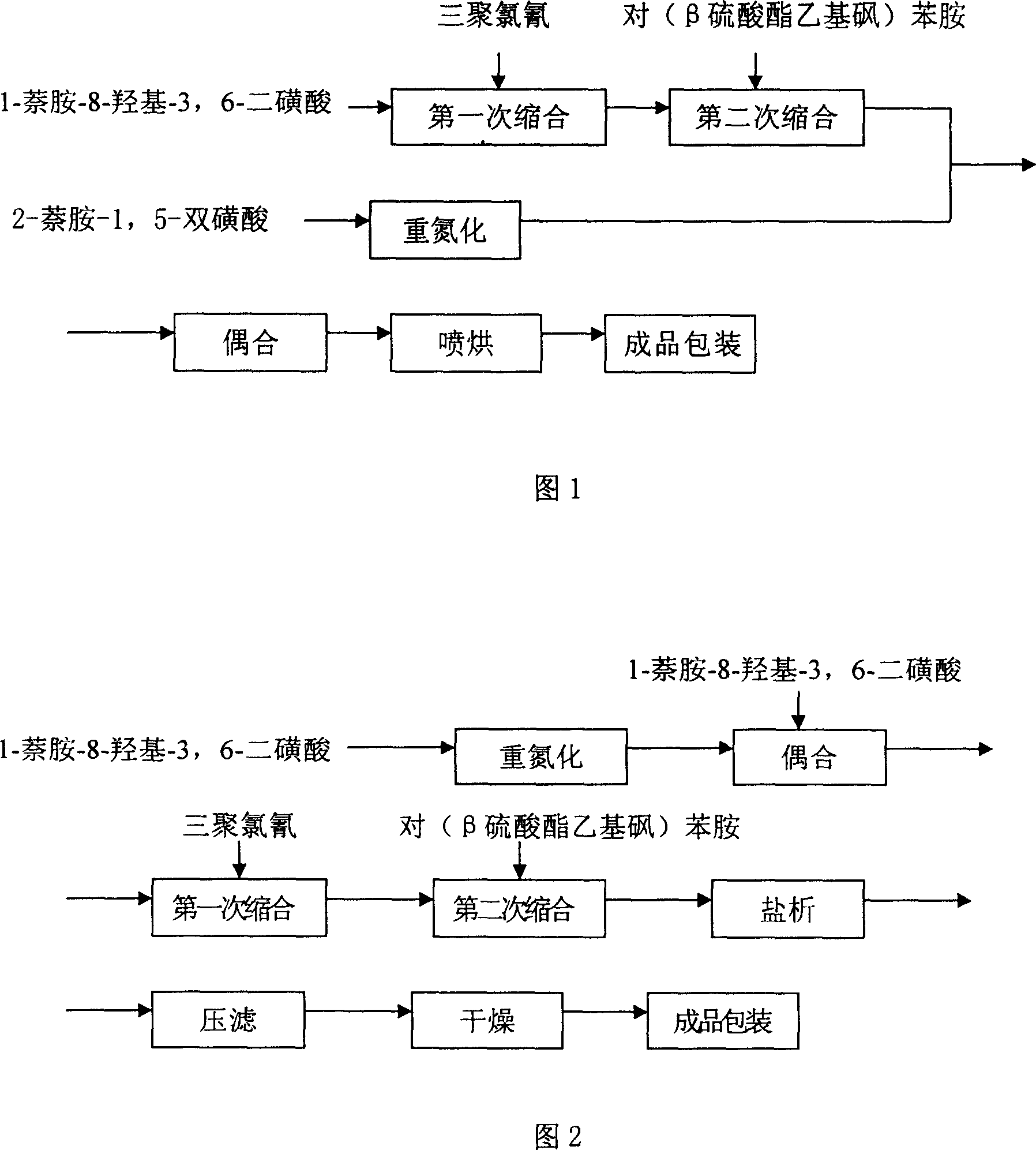

Method used

Image

Examples

Embodiment 1

[0058] 1. Ingredients list

[0059] raw material name

molecular weight

molecular ratio

Percent consumption (kg)

184.5

1.0

149.5

1-naphthylamine-8-hydroxy-3,6-disulfonic acid

341.3

1.0

276.1

p-(beta sulfate ethyl sulfone) aniline

281.3

1.03

234.4

2-Naphthylamine-1,5-disulfonic acid

303

0.98

240.2

69.01

0.98

54.7

36.5

1.0

29.5

[0060] 2, the synthetic method of active red DF-3BS of the present invention operates as follows:

[0061] A. Dissolution of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid:

[0062] Add 276.1kg of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid to 700L of bottom water, add 50kg of sodium dihydrogen phosphate, and 75kg of disodium hydrogen phosphate for beating for 1 hour. Adjust the pH to 6.5 with 10% sod...

Embodiment 2

[0078] A. Dissolution of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid:

[0079] Add 289.9kg of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid to 700L of bottom water, add 60kg of sodium dihydrogen phosphate, and 90kg of disodium hydrogen phosphate for beating for 1 hour. Adjust the pH to 6.4 with 10% soda water.

[0080] B, cyanuric chloride beating:

[0081] Add 200 L of ice water, jacket cooling, drop into 142 kg of cyanuric chloride industrial product ice mill for 1 hour.

[0082] C. One condensation:

[0083] Add the dissolved step A solution into the beaten suspension in about 1.5 hours, adjust the pH to 1.9 with soda water, and react for 2 hours at a temperature of 4°C.

[0084] D. Secondary condensation:

[0085] Put 257.2kg of p-(βsulfate ethyl sulfone) aniline powder into the shrinkage liquid of step C, stir for 10 minutes, uniformly heat up to 45°C in about 1 hour, and adjust the pH to 3.7 with 10% soda water at the same time , reacted for 4 hours.

[0086] E...

Embodiment 3

[0095] A. Dissolution of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid:

[0096] 750L of bottom water, 262.3kg of 1-naphthylamine-8-hydroxyl-3,6-disulfonic acid was added, 55kg of sodium dihydrogen phosphate and 84kg of disodium hydrogen phosphate were added for beating for 1 hour. Adjust the pH to 6.3 with 10% soda water.

[0097] B, cyanuric chloride beating:

[0098] Add 200 L of ice water, cool down the jacket, and put 157.0 kg of cyanuric chloride industrial product into the ice mill for 1 hour.

[0099] C. One condensation:

[0100] Add the dissolved step A solution into the beated suspension in step B within 1 hour and 20 minutes. After the addition, adjust the pH to 2.0 with soda water, and react for 2 hours at a temperature of 5°C.

[0101] D. Secondary condensation:

[0102] Add 211.6 kg of p-(beta sulfate ethyl sulfone) aniline powder to the shrinkage solution of step C, stir for 15 minutes, and uniformly heat up to 45° C. in 50 minutes, while adjusting the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com