Control system for catalytic combustion

A catalytic combustion and control system technology, applied in the combustion, combustion method, combustion type and other directions of using catalytic materials, can solve the problems of bulky volume, complex structure of catalytic burners, increasing the cost and technical difficulty of catalytic combustion control system, etc. Resolve complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

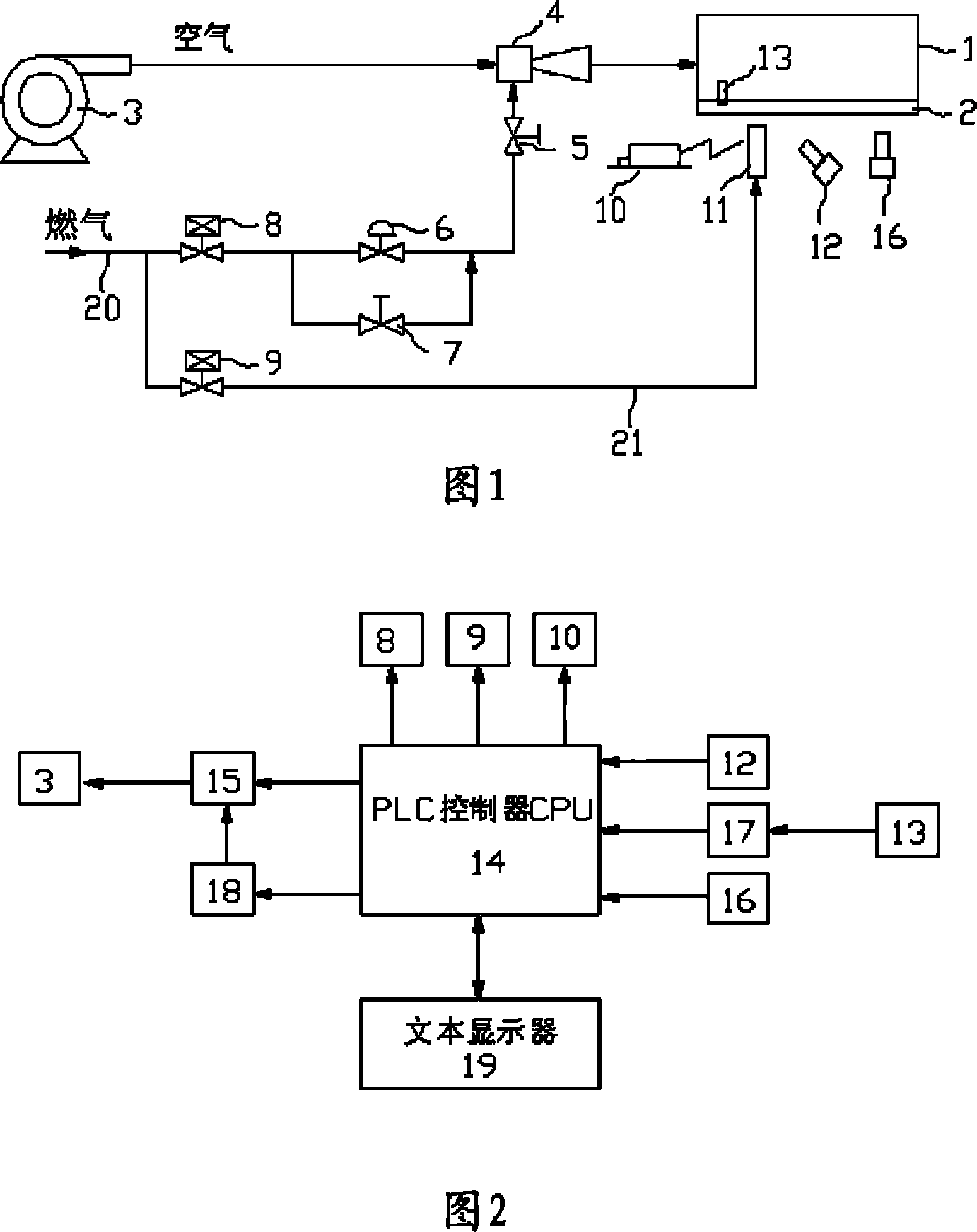

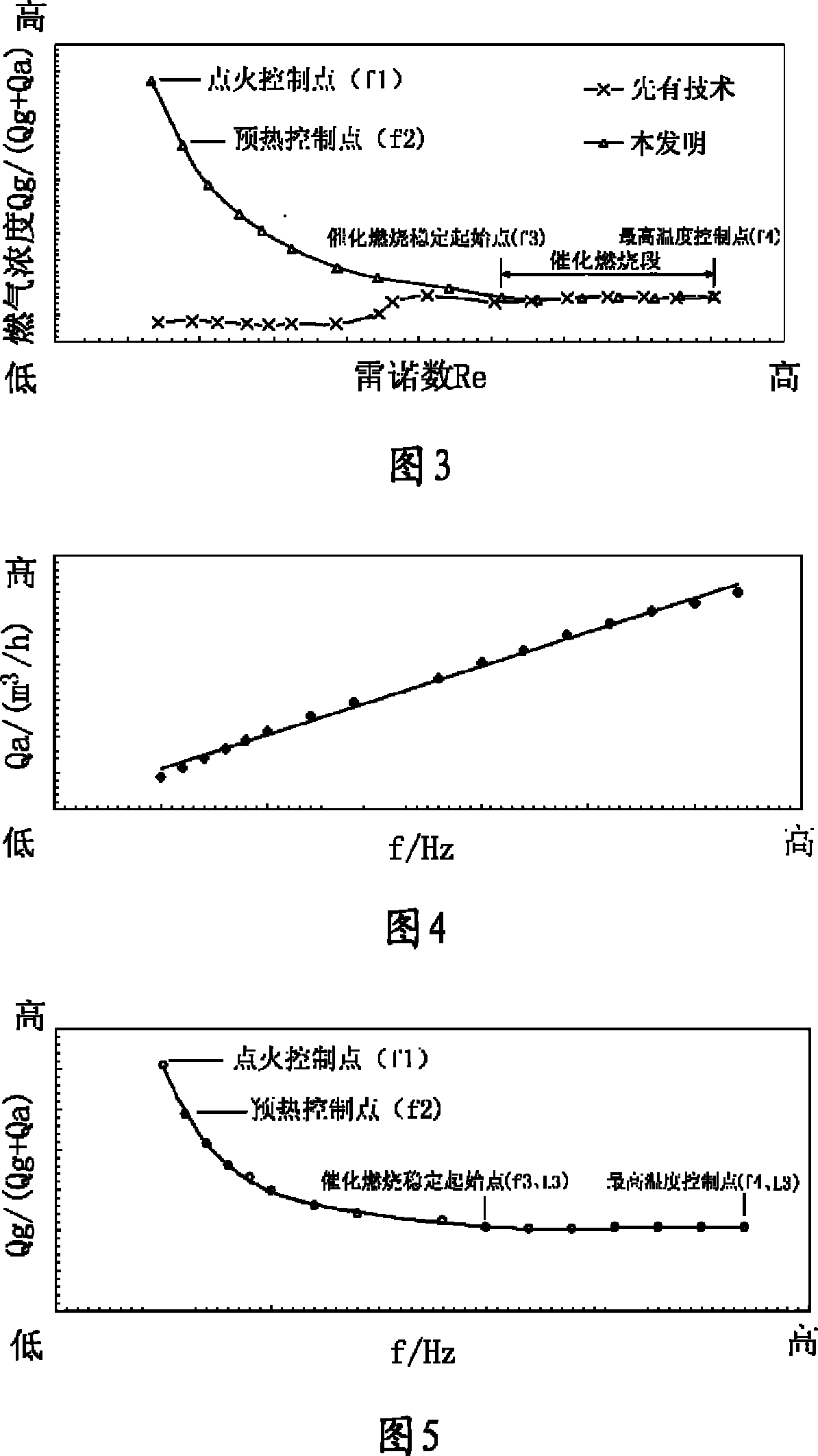

[0049] Referring to Fig. 1 and Fig. 2, the catalytic combustion control system of the present invention is composed of a fluid premix control system and a PLC control device.

[0050] The fluid premixing control system includes: a blower 3 connected in series with a Venturi mixer 4, which is used to purge the catalytic burner 1 and use the Venturi mixer 4 to introduce gas and perform uniform premixing. The output of the Venturi mixer 4 The tuyere is connected to the air inlet of the catalytic burner 1, and the throat suction port of the Venturi mixer 4 is connected to a proportional regulating valve 5, which is used to set the optimal gas premix concentration in the catalytic combustion stage. The inlet of the proportional regulating valve 5 is connected to the The outlet connection of a zero-pressure valve 6 is used to ensure that the gas entering the proportional regulating valve 5 is close to normal pressure. The inlet and outlet ends of the zero-pressure valve 6 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com