Grain drying device

A grain drying and hot air technology, applied in heating devices, drying solid materials, heating to dry solid materials, etc., can solve the problems of unit energy consumption, drying efficiency, clean and hygienic defects, large heat transfer coefficient, and large working noise, etc. Superior drying performance, reduced pollution, and guaranteed quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the grain drying device of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not used to limit the protection scope of the present invention.

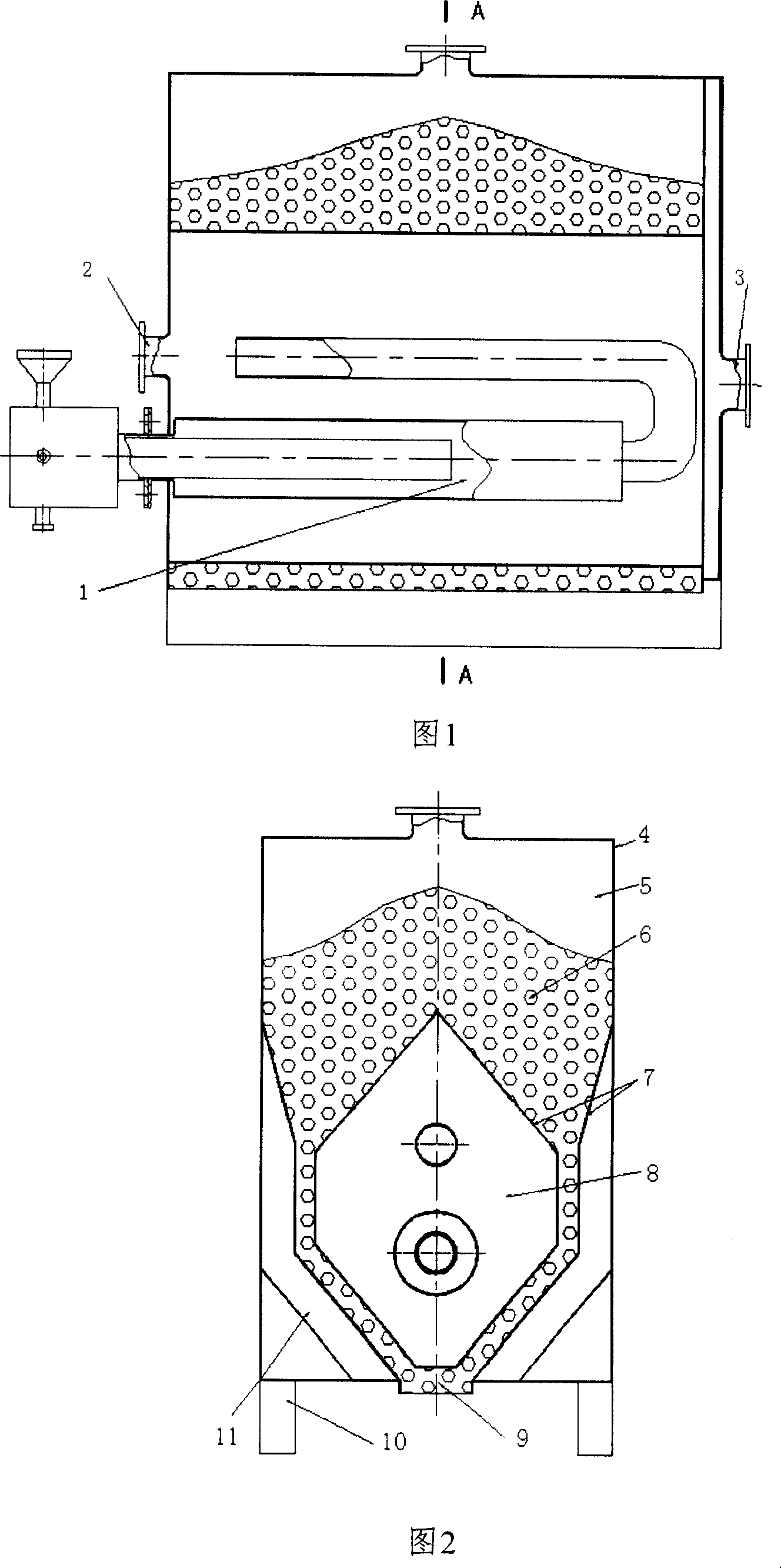

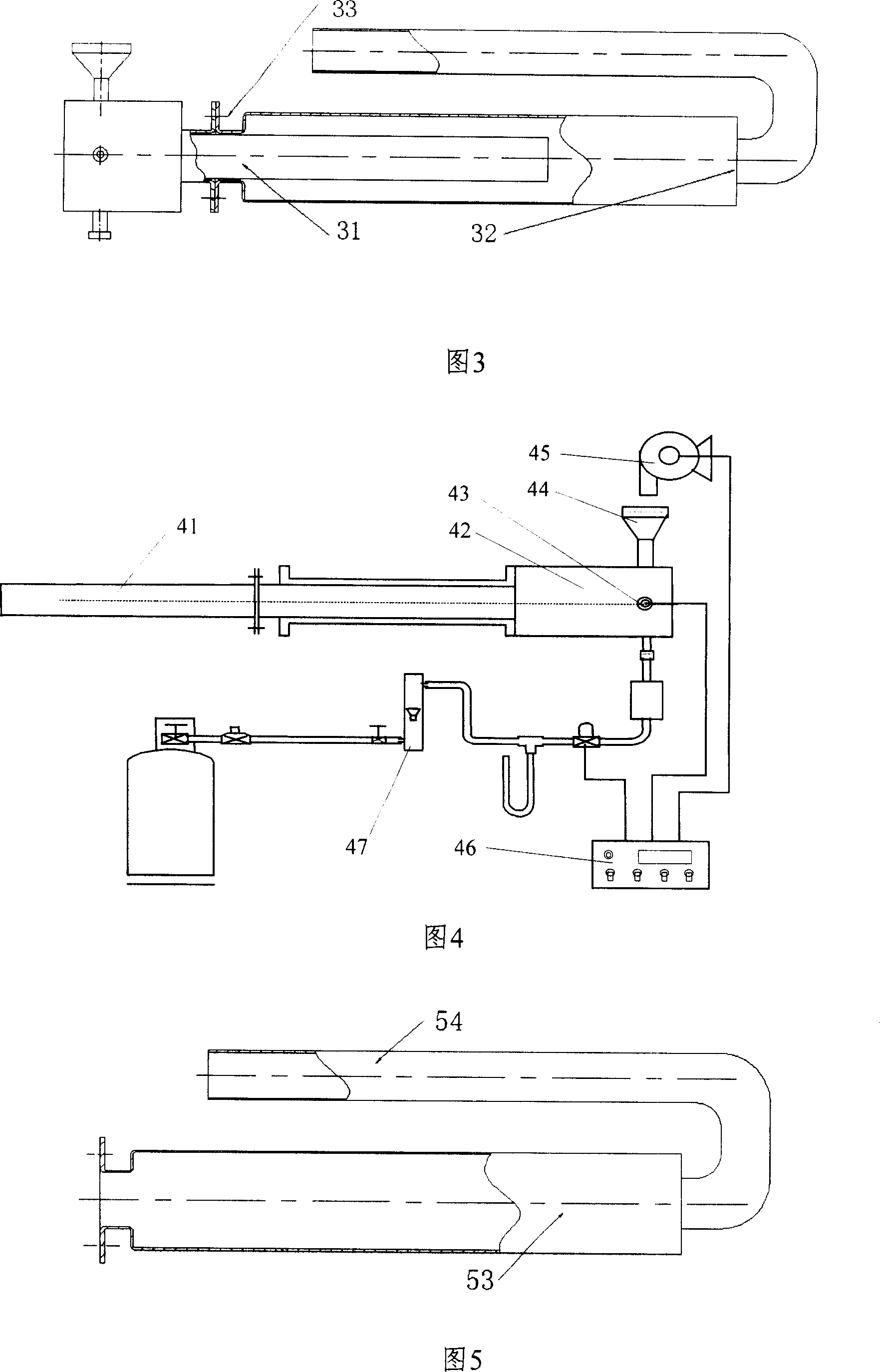

[0030] As shown in Figure 1 and Figure 2, the grain drying device of the present invention includes a heat source generator 1, an air inlet 2, an air introduction port 3, a box body 4, a feed bin 5, an orifice plate 7, a hot air radiation bin 8, and a discharge port 9 , base 10 and exhaust bin 11. Wherein the box body 4 is fixed on the base 10, and the orifice plate 7 divides the inner space of the box body 4 into a feed bin 5, a hot air radiation bin 8 and an exhaust bin 11; the air inlet 2 is fixed on the left side of the box body 4 Corresponding to the mouth of the secondary infrared radiation tube 54 (see Figure 5), and communicated with the hot air radiation chamber 8, the air introduction port 3 is fixed on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com