Process of extracting rhanolipid as biosurfactant

A rhamnolipid, biological surface technology, applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of complex composition, complex rhamnolipid process, limitations, etc., and achieve a simple operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

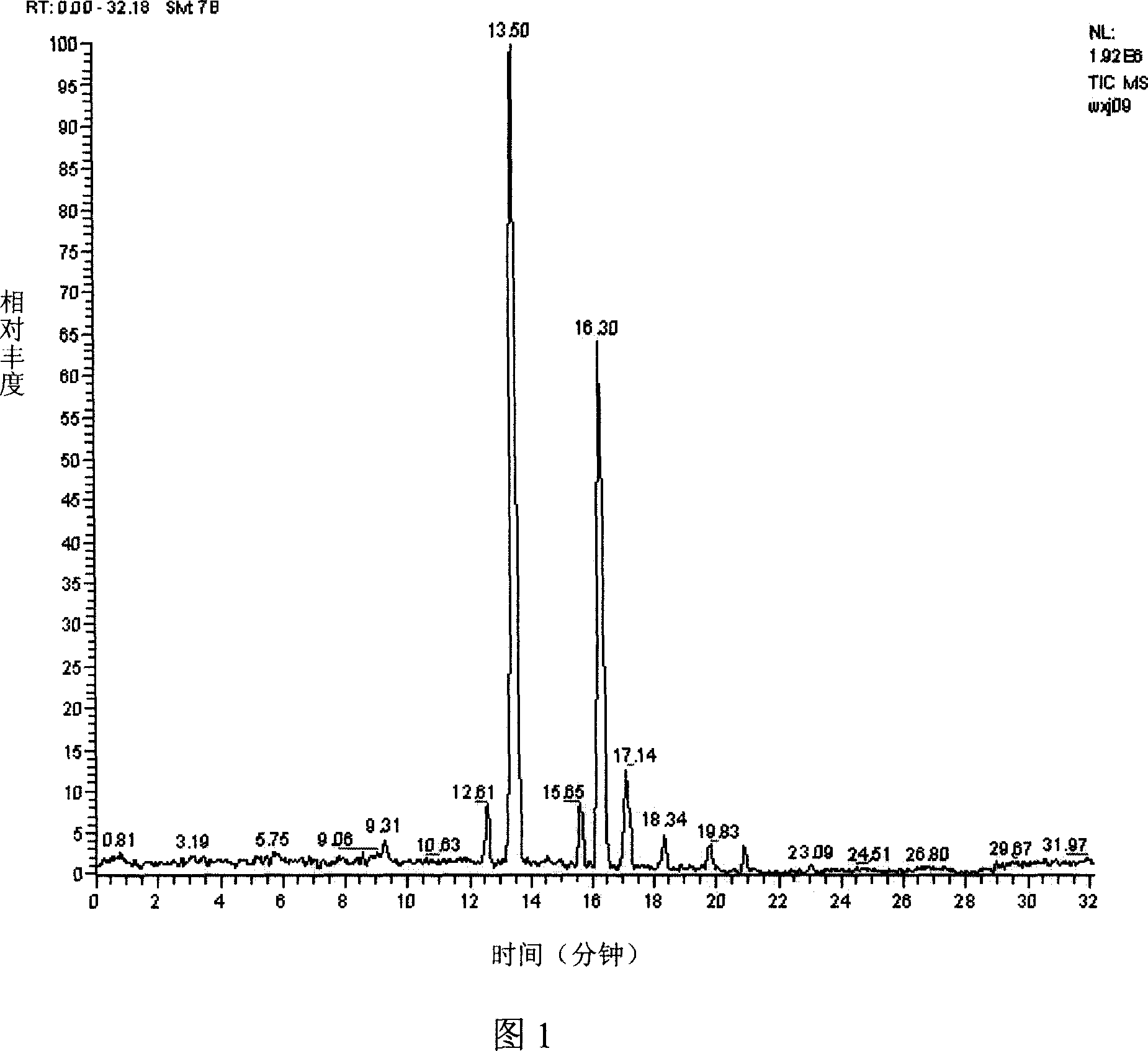

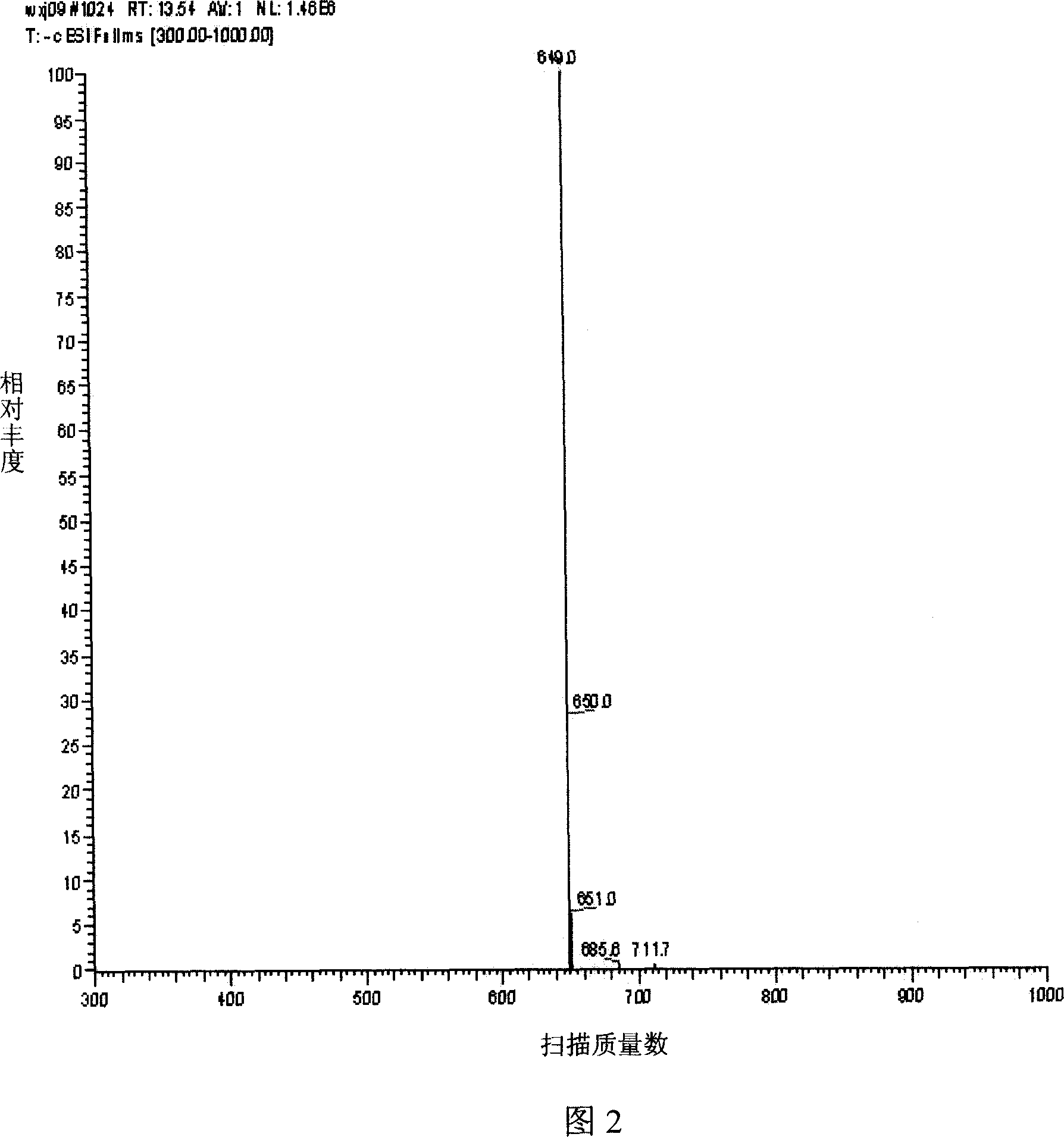

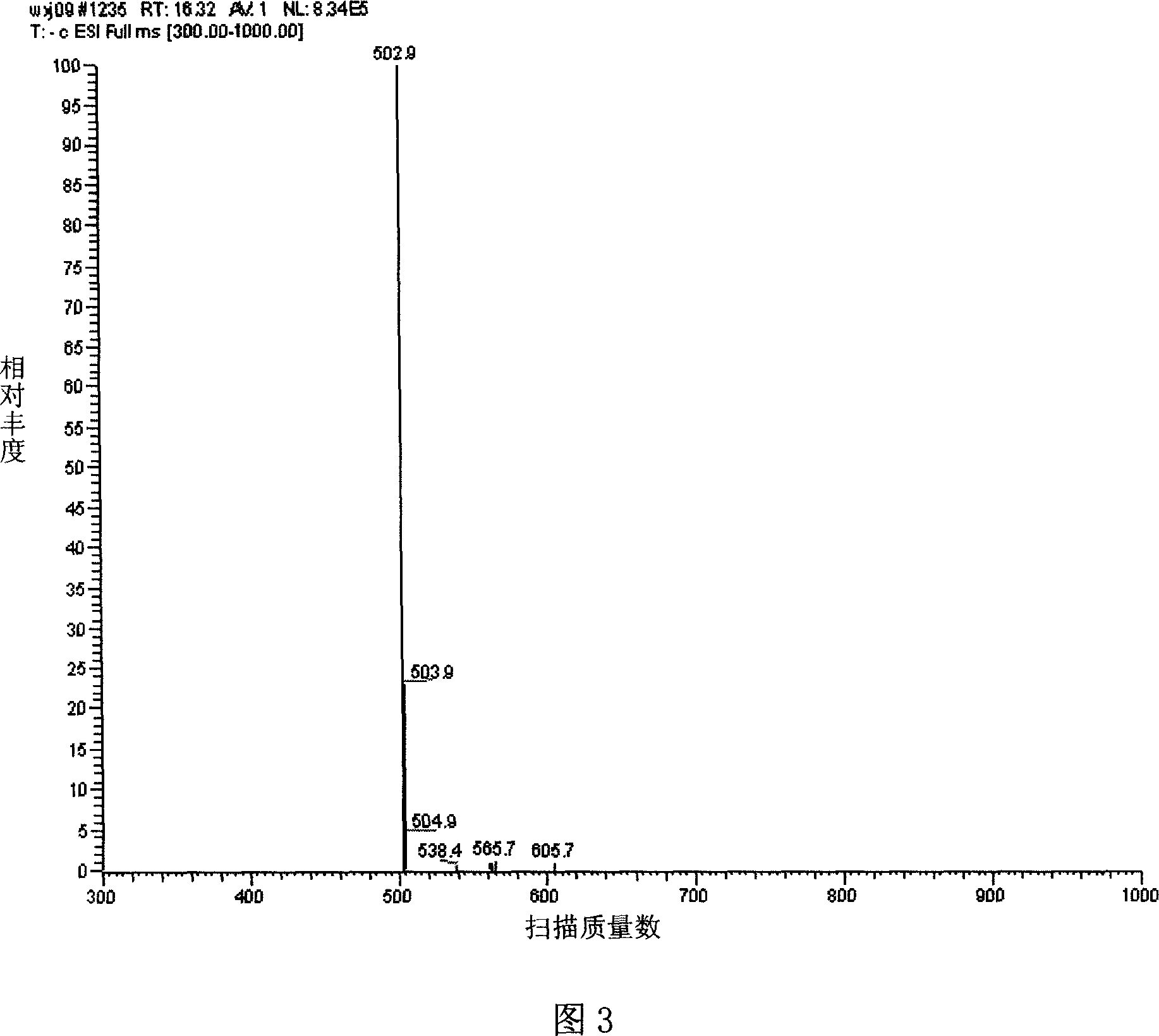

Image

Examples

Embodiment Construction

[0040] 1. Preparation of rhamnolipid fermentation broth:

[0041] 1) Inoculate Pseudomonas aeruginosa from the slant culture medium into the seed medium, and carry out shake flask culture, and put 80mL of seed culture solution in a 500mL Erlenmeyer flask. Culture conditions: temperature 37°C, time 24 hours, rotation speed 200 rpm.

[0042] 2) Put 250mL of fermentation medium with soybean oil as carbon source in each 1L fermenter, inoculate 7mL of Pseudomonas aeruginosa seed culture solution, culture conditions: 37°C, use HCl or NaOH to control the pH value to 7.0, and The culture was shaken at 250 rpm for 96 hours. Obtain about 230 mL of fermentation broth in each fermentor, and collect the fermentation broth in all fermentors together.

[0043] Note: See Table 1 and Table 2 for the formulations of subculture slant medium and seed medium. The formulation of the fermentation medium is: crude soybean oil 120g / L, NaNO 3 8.0g / L,KH 2 PO 4 1.0g / L, Na 2 HPO 4 .12H 2 O 1.0g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com