Production technology of extracting oat starch and oat protein powder from oat

A technology of oat protein and protein powder, which is applied in the direction of hydrolytic enzymes, etc., can solve the problems of high cost of enzymatic methods, and achieve the effects of low gluten content, reduced gluten content, and reduced crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

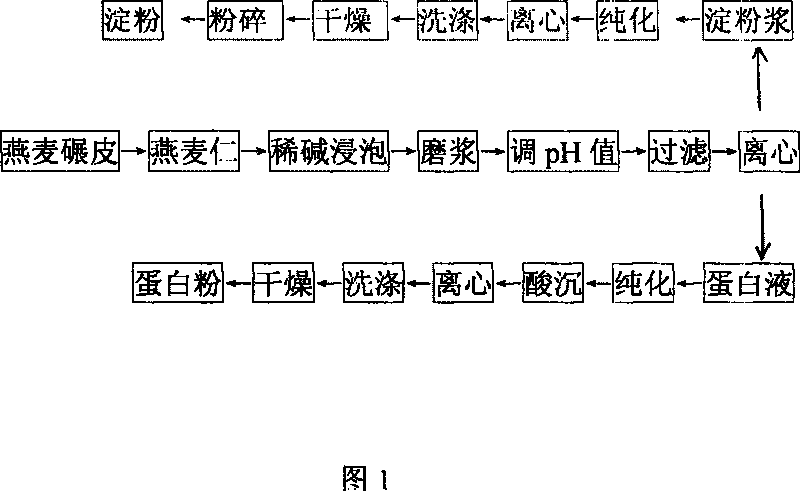

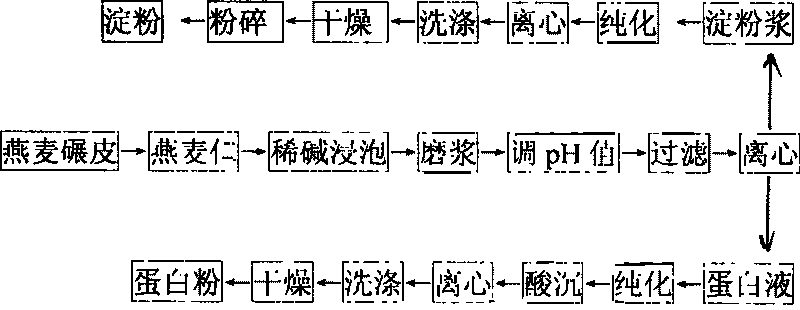

[0030] A kind of production technology of oat starch, oat protein powder,

[0031] Include the following steps:

[0032] 1. Oat kernels are obtained by grinding oats; the grinding rate is 13%.

[0033] 2. Soak oat kernels, the conditions are pH=9, solid-liquid ratio 1:5, time 1.8h, room temperature.

[0034] 3. Grind the soaked oat kernels; adjust the pH of the ground slurry to 9-10, stir for 30 minutes, and then filter with an 80-mesh sieve to remove cellulose and other materials.

[0035] 4. Centrifugal separation to obtain oat starch and oat protein liquid; through centrifugal separation, the filtered slurry material is divided into supernatant (protein liquid) and sediment (starch slurry), and the LXJ-II desktop centrifuge is used for separation. 3000r / min, time 15min.

[0036] 5. The purification of oat starch adopts alkaline protease, the ratio of enzyme to substrate is 48ΔU / Kg, the temperature is 40°C, the mass ratio of material to water is 1:6-8, pH=8-9, and the tim...

Embodiment 2

[0041] Step is with embodiment 1

[0042] In step 1, the peeling rate was 18%. In step 2, the conditions are pH=10, the ratio of material to liquid is 1:7, and the time is 1.5h. In step 3, the pH value of the ground slurry is adjusted to be 10, and the stirring time is 30-60min, and then a 100-mesh sieve is used. Filtration to filter out materials such as cellulose. In step 5, the ratio of enzyme to substrate is 60ΔU / Kg, the temperature is 50°C, the mass ratio of material to water is 1:8, pH=8-9, and the time is 60 minutes. In step 6, the drying temperature is 40° C., in step 7, the ratio of enzyme to substrate is 55 U / g, pH=6, the temperature is 40° C., and the time is 20 minutes.

Embodiment 3

[0044] Step is with embodiment 1

[0045] In step 1, the peeling rate is 15-16%. In step 2, the conditions are pH=9.5, the ratio of solid to liquid is 1:6, and the time is 2h. In step 3, the pH value of the ground slurry is adjusted to be 9-10, and the stirring time is 45min, and then filtered with a 90-mesh sieve , to filter out materials such as cellulose, in step 5, the ratio of enzyme to substrate is 48ΔU / Kg, the temperature is 45°C, the mass ratio of material to water is 1:7, pH=8~9, and the time is 40 minutes. In step 6, the drying temperature is 35° C., in step 7, the ratio of enzyme to substrate is 60 U / g, pH=5.5, the temperature is 35° C., and the time is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com