Method for producing ultramicro edible nutrient yeast powder and its product

A production method and technology of yeast powder, applied in fungi and other directions, can solve problems such as ineffective utilization of nutrients, and achieve the effects of improving bioavailability, less energy consumption, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

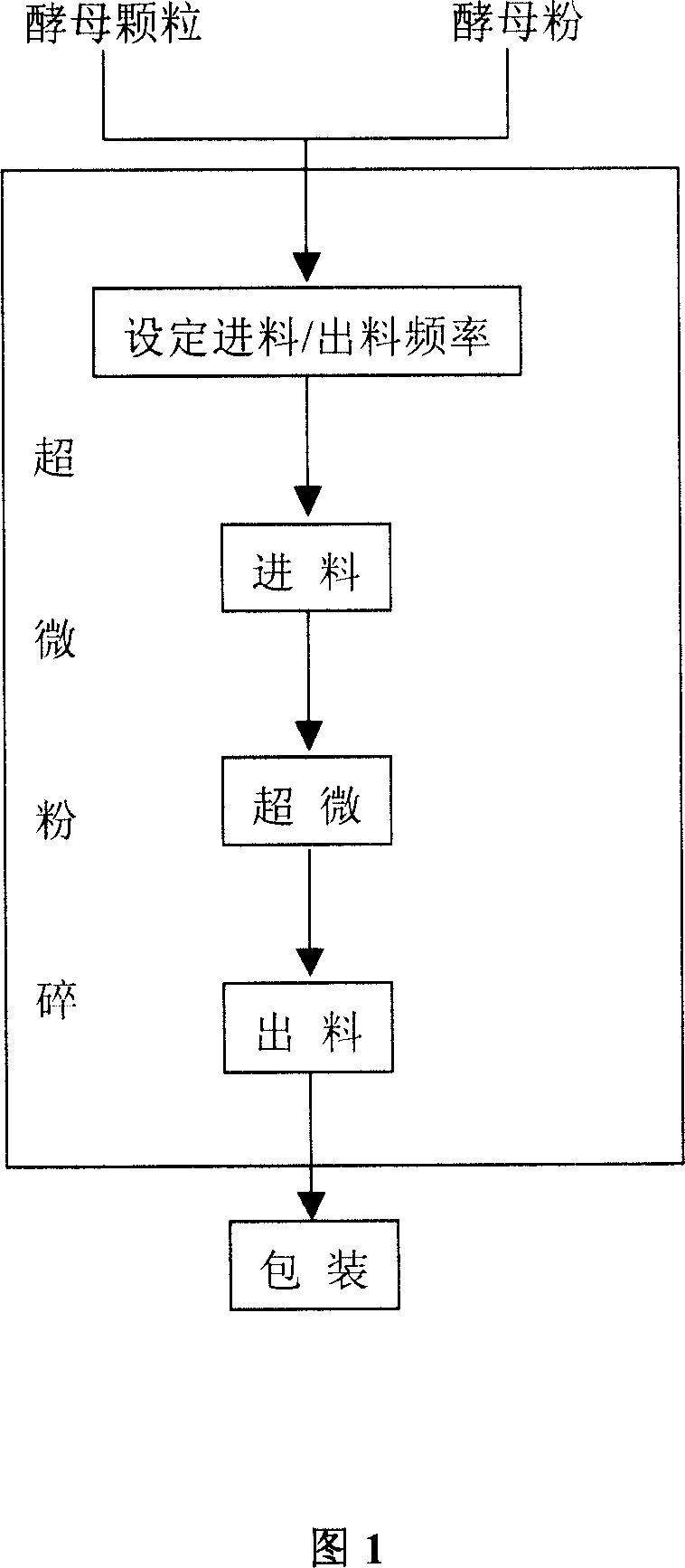

[0017] Embodiment 1: the ultramicro treatment of granular yeast

[0018] Source and specifications of granular yeast: Yeast for angel noodles, particle diameter ≤ 500 μm, moisture content ≤ 8%.

[0019] Ultra-fine equipment: "Berry" BM-100S micro-powder machine, provided by Jinan Beili Powder Technology Engineering Co., Ltd.

[0020] Specific steps:

[0021] (1) Set the feed frequency to 1-15Hz; set the discharge frequency to 5-40Hz.

[0022] (2) Automatic feeding according to the selected frequency.

[0023] (3) The yeast cells are squeezed and impacted by the movement of the grinding medium in the pulverizer, and the particles are continuously crushed from large to small. During the crushing process, the large particles are first subjected to force and crushed first.

[0024] (4) After crushing, the particles are discharged according to the selected frequency. Feeding, crushing and discharging are carried out continuously.

[0025] (5) The ultra-fine material directly e...

Embodiment 2

[0027] Embodiment 2: the ultrafine treatment of powdery yeast

[0028] Source and specifications of powdered yeast: Angel nutritional yeast powder, see Table 1 for particle size distribution.

[0029] Ultra-fine equipment: "Berry" BM-100S micro-powder machine, provided by Jinan Beili Powder Technology Engineering Co., Ltd.

[0030] Specific steps:

[0031] (1) The feed frequency is set to 3.4Hz, and the discharge frequency is set to 20Hz.

[0032] (2) Other steps are the same as in Example 1.

[0033] The cell wall breaking rate of the ultrafine edible nutritional yeast powder produced in this example is 80%, and the particle diameter is ≤10 μm. Protein is 48%, moisture is 4%, ash is 5.6%.

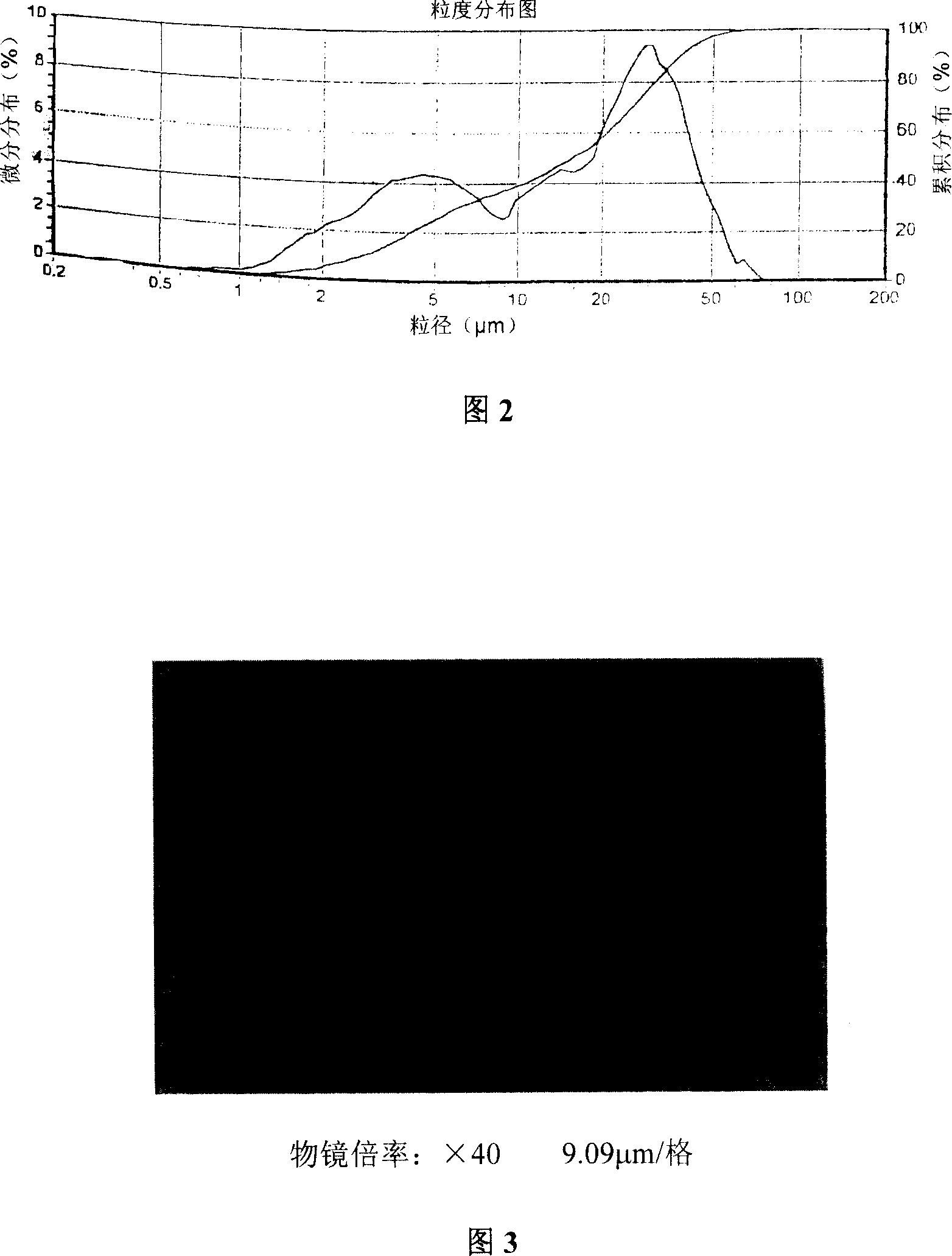

[0034] The particle size distribution of the yeast powder before ultramicronization is shown in Table 1, and the particle size distribution diagram and microscopic image are shown in Figure 2 and Figure 3, respectively.

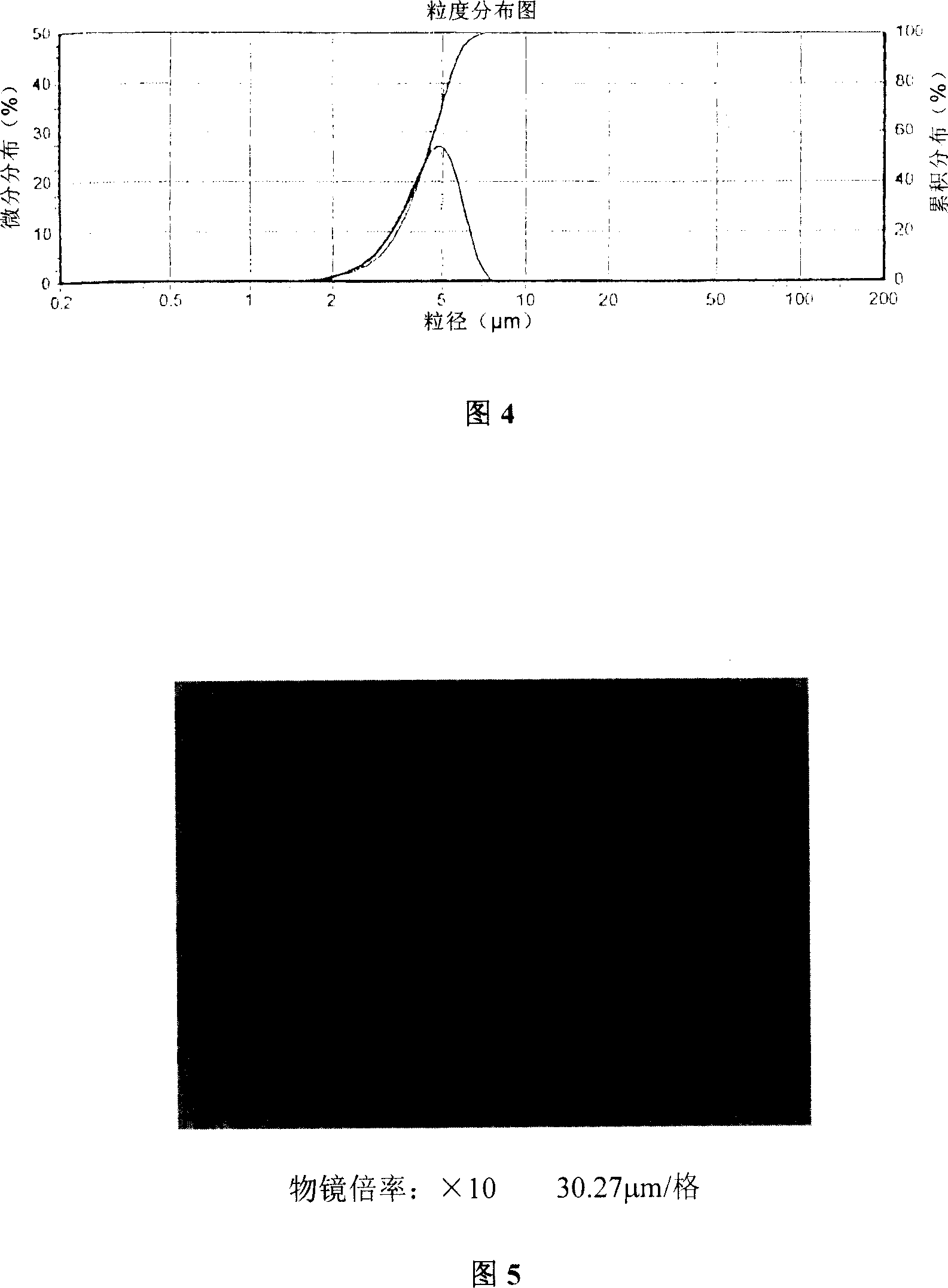

[0035] After micronization, the particle size distribution of t...

Embodiment 3

[0041] Embodiment 3: edible zinc-enriched yeast superfine treatment

[0042] In this embodiment, Angel zinc-rich yeast (produced by Hubei Yichang Angel Yeast Co., Ltd.) with a zinc content of 5000 mg / kg is subjected to ultrafine treatment, and the specific method is the same as that in Example 2.

[0043] According to the following animal experiments, the bioavailability of zinc-enriched yeast ultrafine was determined.

[0044] (1) Take 39 male Wistar rats. The body weight is 40-60 grams. Randomly divided into 13 groups according to body weight, fed with zinc-deficient feed, and after the appearance of the model, the metabolic experiment was carried out. The zinc source was ultrafine zinc-enriched yeast. The intragastric dose was calculated as 4.99mg / kg body weight based on zinc, and the intragastric volume was 1.5ml. / 100g body weight. After gavage, collect urine and feces according to different time periods (0 (before gavage), 0.5, 1, 3, 5, 7, 9, 11, 13, 15, 18, 21, 24h),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com