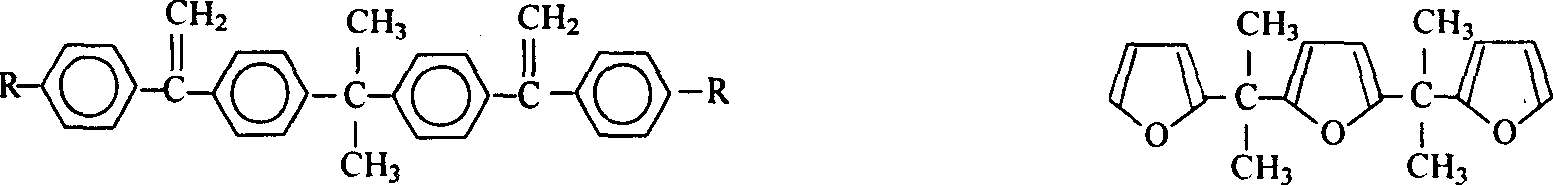

Production of soft-segment total saturated block copolymer

A block copolymer and soft segment technology, which is applied in the field of block copolymer preparation, can solve the problems of inconvenient industrial application, high price, and increased cost, and achieve the effect of simple method, low cost, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]At -60°C and under the protection of high-purity nitrogen, 9ml of dichloromethane (CH 2 Cl 2 ), 9ml n-hexane (n-Hex), 4.4×10 -3 mmol H 2 O, 24mmol isobutene and 0.132mmol N,N-dimethylacetamide were mixed evenly, and after precooling for half an hour, 2mmol TiCl was added 4 Initiate polymerization, after polymerization reaction 60 minutes, add the styrene solution (concentration is 1.0mol / L, CH 2 Cl 2 / n-Hex=1 / 1) to continue the polymerization. After 50 minutes, 10 mL of ethanol / water (V / V=50 / 50) mixed solution containing 1 wt% NaOH was added to terminate the polymerization. After removing the solvent and unreacted monomers, the polymerized product was washed and purified with water several times, and dried in vacuum at 40°C until constant weight. The conversion rate of isobutylene in the first stage is 99.2%, and the weight average molecular weight of the polyisobutylene segment is 8.1×10 4 ; The peak molecular weight is 8.7×10 4 ; Molecular weight distribution i...

Embodiment 2

[0033] Add 9ml of CH 2 Cl 2 , 9ml n-Hex, 2.0×10 -4 mmol H 2 O, 24 mmol isobutene, 0.10 mmol acetone and 0.03 mmol N, N-dimethylacetamide were mixed evenly, and after half an hour of pre-cooling, 2 mmol TiCl was added 4 Initiate polymerization, after polymerization reaction 60 minutes, add 24ml and contain 0.036mmol 2, the p-methylstyrene solution of 6-di-tert-butylpyridine, 0.12mmol acetone and 0.03mmol N, N-dimethylacetamide (concentration is 1.0mol / L, CH 2 Cl 2 / n-Hex=1 / 1) to continue the polymerization reaction. After 70 minutes, 10 mL of ethanol / water (V / V=50 / 50) mixed solution containing 1 wt% NaOH was added to terminate the polymerization. After removing the solvent and unreacted monomers, the polymerized product was washed and purified with water several times, and dried in vacuum at 40°C until constant weight. The conversion rate of isobutylene in the first stage is 99.7%, and the weight average molecular weight of the polyisobutylene segment is 7.18×10 4 ; The...

Embodiment 3

[0035] Add 26ml CH 2 Cl 2 , 26ml n-Hex, 3.74×10 -4 mmol H 2 O, 10.4mmol styrene and 0.40mmol N,N-dimethylacetamide were mixed evenly, and after precooling for half an hour, 6.4mmol TiCl was added 4 The polymerization was initiated, and after 70 minutes of polymerization, a small amount of sample was taken out to measure the molecular weight of polystyrene. Add 58mmol of isobutylene to continue the second stage of polymerization, react for 80 minutes, and take out a small amount of sample to measure the molecular weight of polystyrene-b-polyisobutylene copolymerization product. Then add 7ml of styrene solution containing 0.06mmol N,N-dimethylacetyl (concentration is 2.0mol / L, CH 2 Cl 2 / n-Hex=1 / 1) proceed to the third stage of polymerization. After 50 minutes, 20 mL of ethanol / water (V / V=50 / 50) mixed solution containing 1 wt % NaOH was added to terminate the polymerization. After removing the solvent and unreacted monomers, the polymerized product was washed and purified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com