Method and device for stabilizing double-longitudinal mold laser frequency based on thermoelectric cryostat

A thermoelectric cooler and laser technology, applied in the field of laser applications, can solve the problems of easy vibration, large creep of piezoelectric materials, large difference between preheating effect and preheating time, etc., so as to improve anti-interference ability, Good consistency, avoid the effect of one-way drift of optical frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

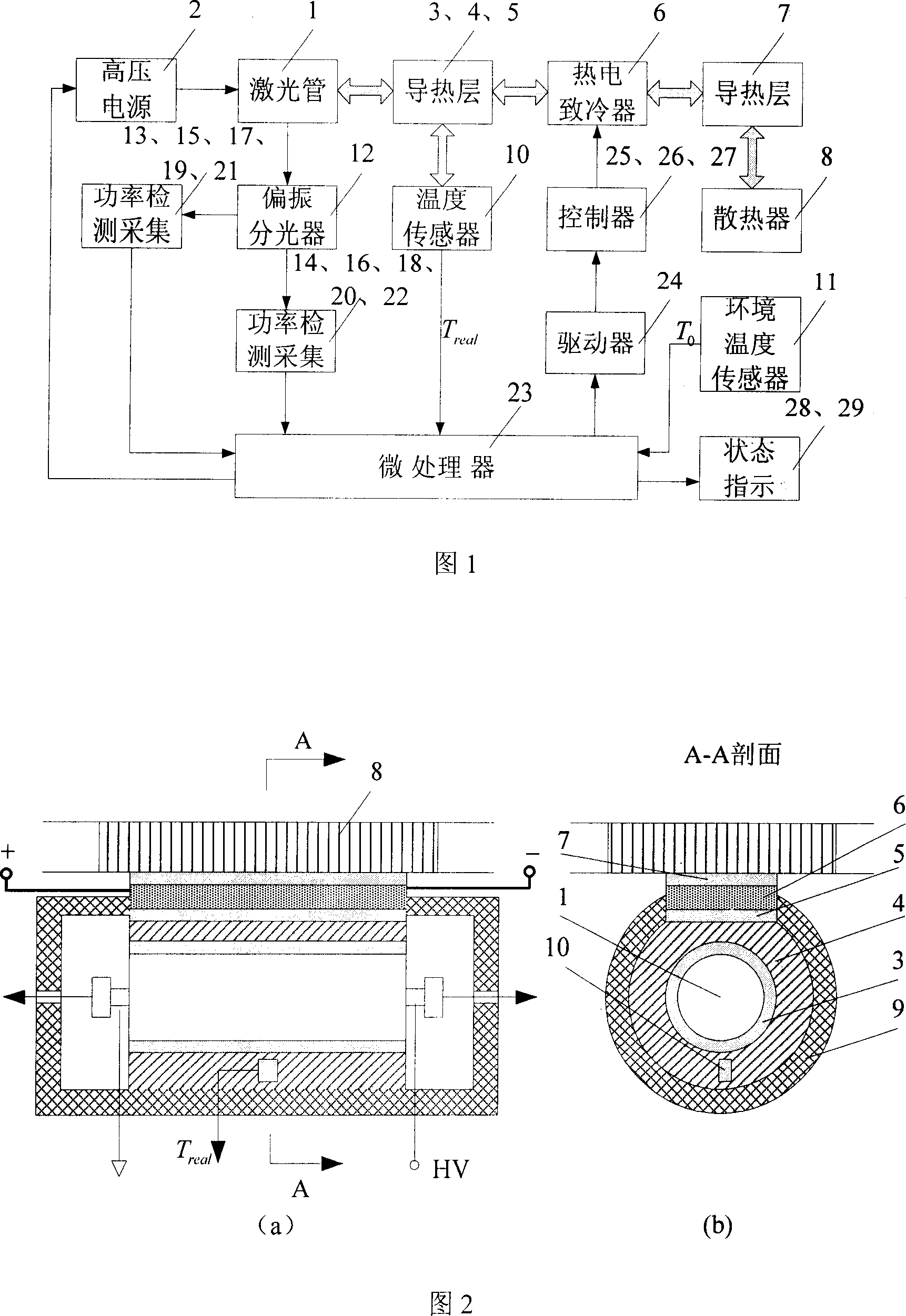

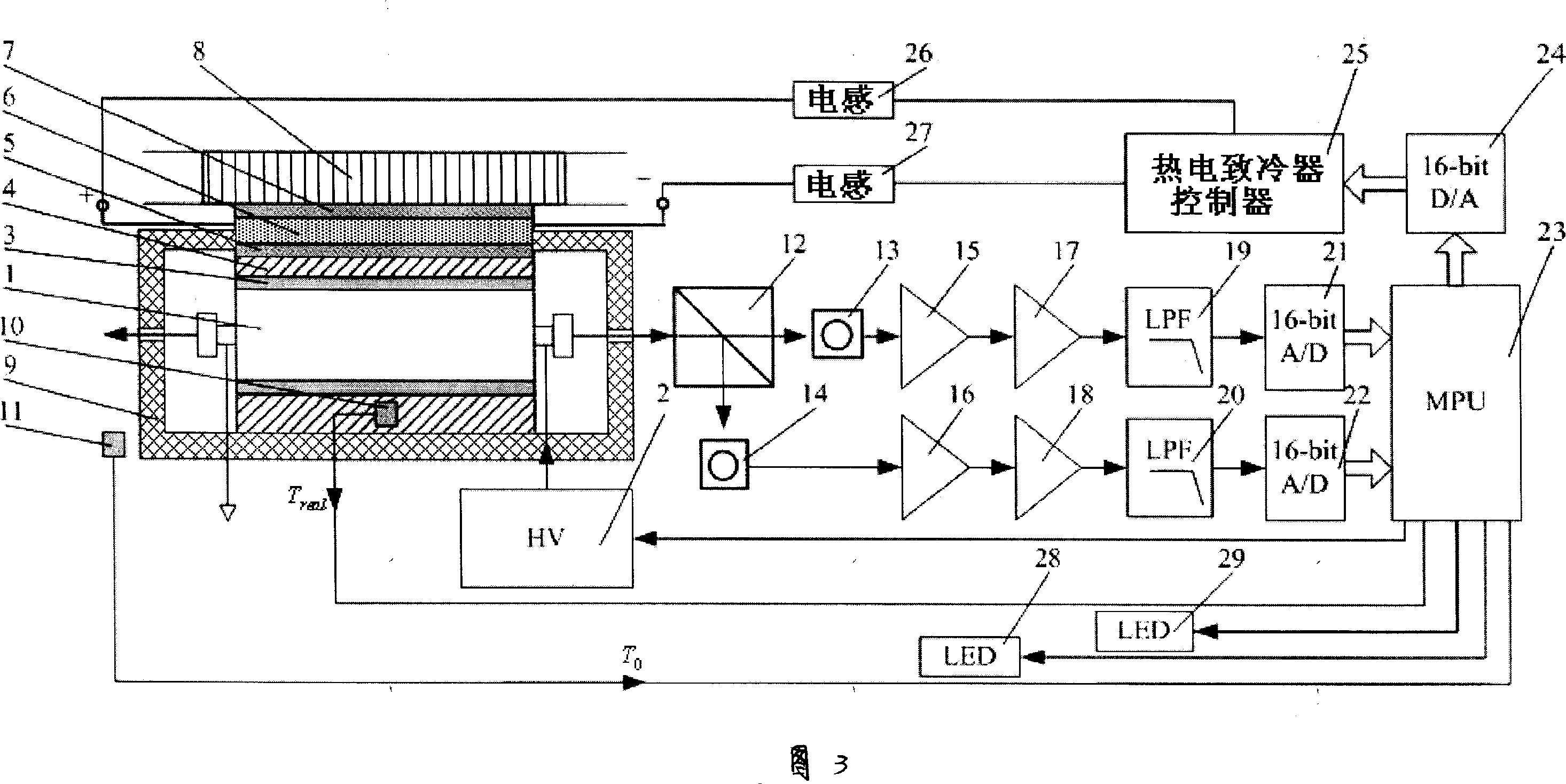

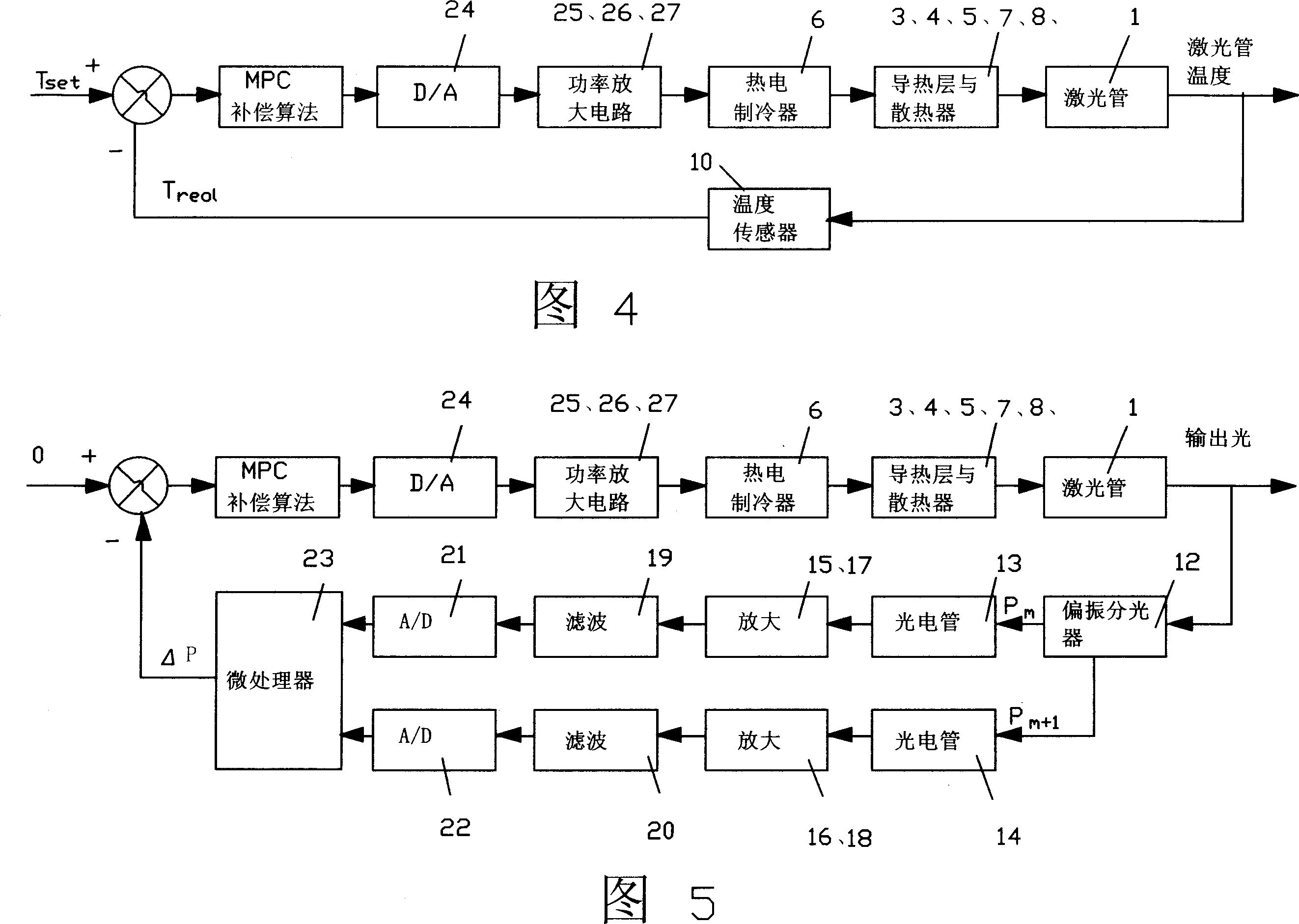

[0032] The technical solution of the present invention is: a method for stabilizing frequency of a dual longitudinal mode laser based on a thermoelectric cooler, the method comprising the following steps

[0033] (1) Measure the ambient temperature T of the laser 0 , according to the ambient temperature T 0 Determine the thermal equilibrium temperature T of the laser tube of the dual longitudinal mode laser after it is naturally turned on at this ambient temperature set .

[0034] (2) Turn on the laser high-voltage power supply 1, and measure the current temperature T of the laser tube in real time real , add a reverse current I to the thermoelectric cooler and according to the current temperature T real and thermal equilibrium temperature T set The difference continuously adjusts the value of the reverse current I, heats the laser tube 1, and makes its temperature approach the thermal equilibrium temperature T set . Simultaneously measure the optical power P of the m-or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com