Production process of viscose filament with nano chitin

A technology of nano-chitin and viscose filaments, which is applied in the field of antibacterial viscose filament fiber production, can solve the problems of single fiber components, single functions, and failure to maximize additional functions and values, so as to improve special functions and expand Field of application, effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

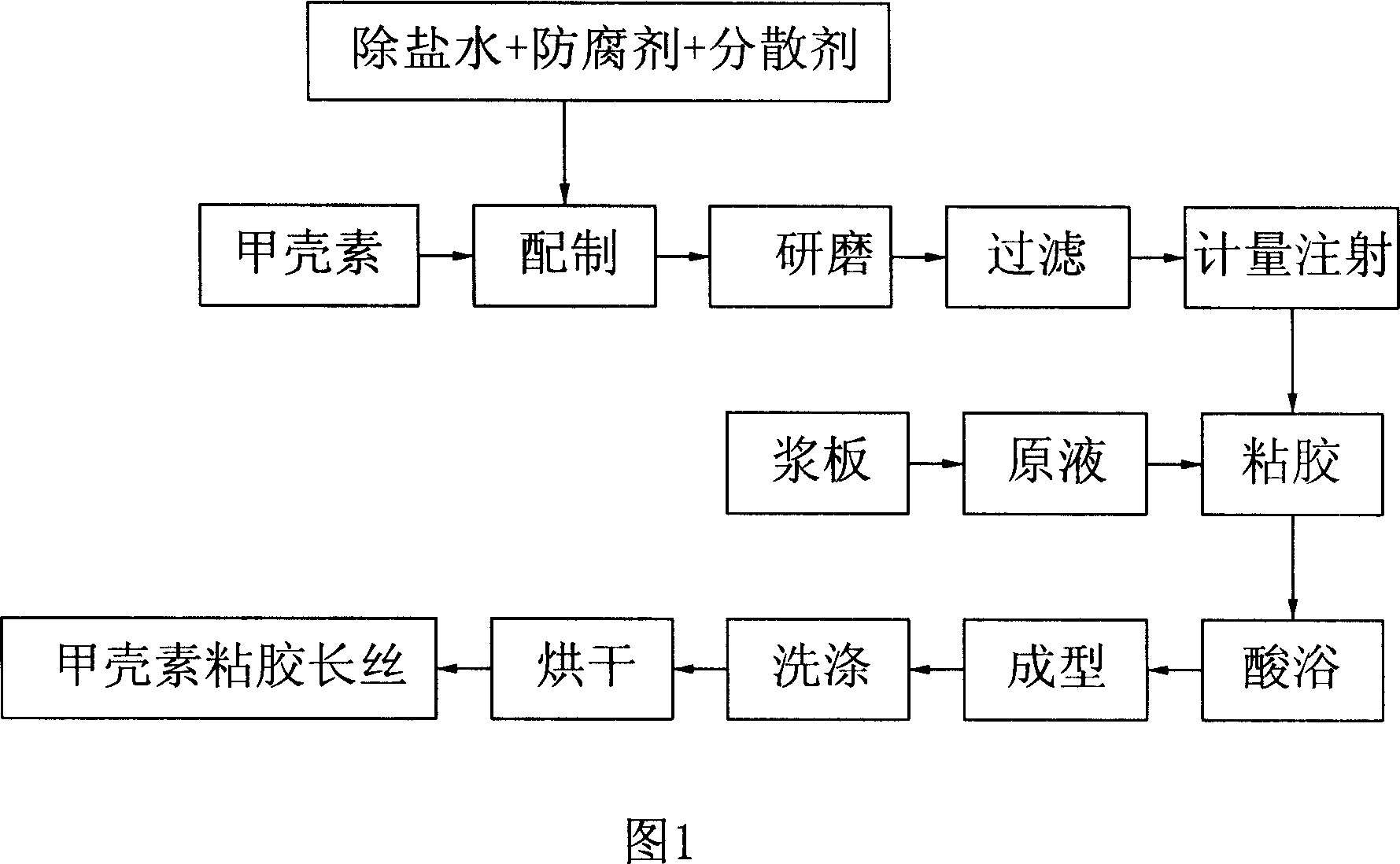

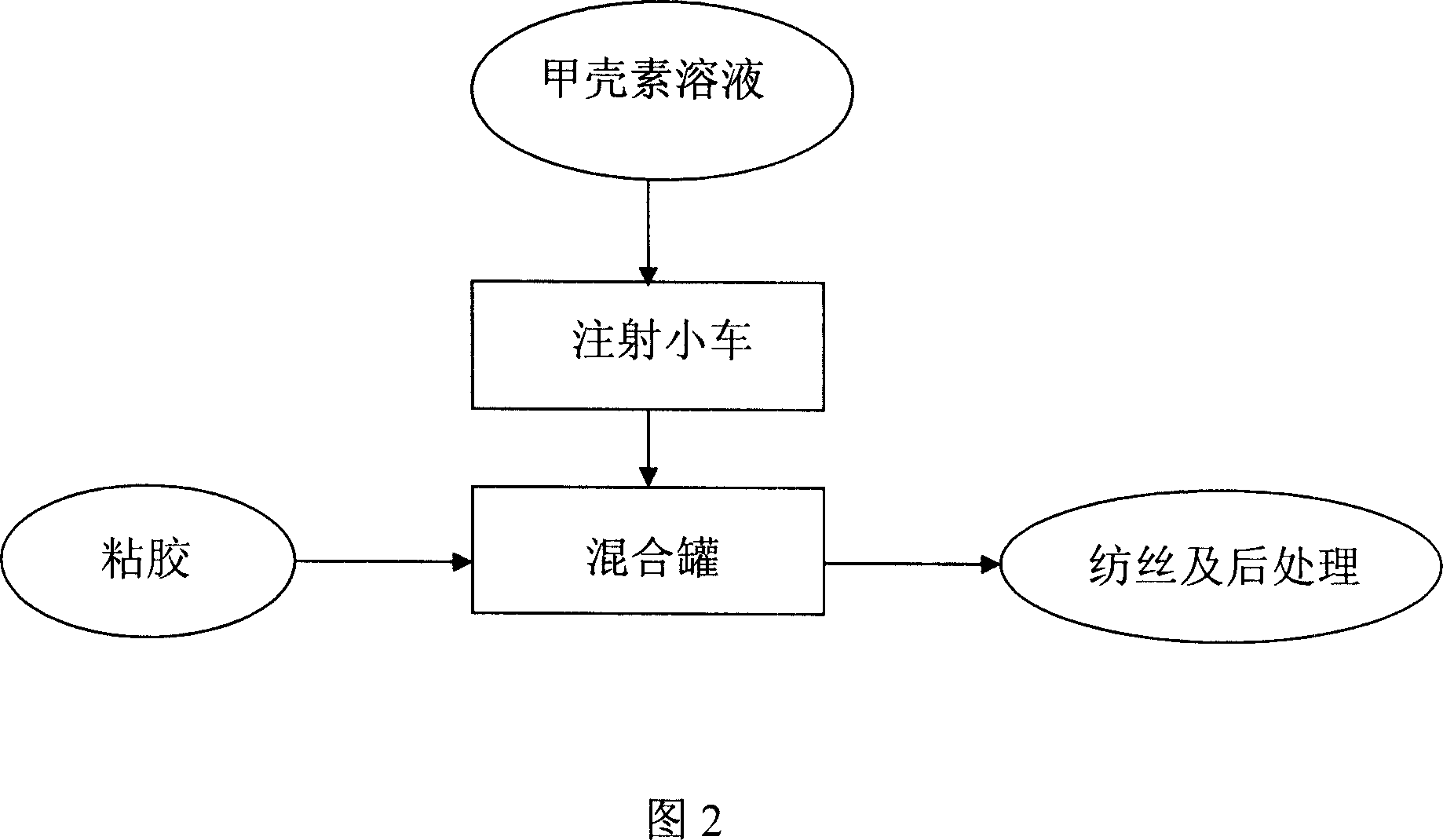

[0025] A production method of nano chitin viscose filaments, including mixing, grinding, filtering, injection, acid bath, forming, washing, drying, adding chitin, desalted water and auxiliary agents in the mixing process to prepare chitin solution ; In the injection process, after the chitin mixed liquid obtained in the filtering process is suction-filtered, the injection trolley adds the chitin mixed liquid obtained in the filtering process into the spinning stock solution according to the ratio of 20ml:1L through the injection control system.

[0026] Said mixing, grinding, and filtering refer to mixing chitin with desalted water at a mass ratio of 1:20 at room temperature, then adding 18% additives according to the mass ratio of chitin and fully mixing, and grinding to a particle size of ≤ 20u of suspended solids.

[0027] Described auxiliary agent comprises dispersant CH-12, AMP-95, polyethylene glycol, defoamer 642, preservative CI-15, dispersant CH-12, AMP-95, polyethyle...

Embodiment 2

[0036] A production method of nano chitin viscose filaments, including mixing, grinding, filtering, injection, acid bath, forming, washing, drying, adding chitin, desalted water and auxiliary agents in the mixing process to prepare chitin solution ; In the injection process, after the chitin mixed liquid obtained in the filtering process is suction-filtered, the injection trolley adds the chitin mixed liquid obtained in the filtering process into the spinning stock solution according to the ratio of 20ml:1L through the injection control system.

[0037] Said mixing, grinding, and filtering refer to mixing chitin with desalted water at a mass ratio of 1:21 at room temperature, then adding 19.5% additives according to the mass ratio of chitin and fully mixing, and grinding to a particle size of ≤ 20u of suspended solids.

[0038]Described auxiliary agent comprises dispersant CH-12, AMP-95, polyethylene glycol, defoamer 642, preservative CI-15, dispersant CH-12, AMP-95, polyethyl...

Embodiment 3

[0047] A production method of nano chitin viscose filaments, including mixing, grinding, filtering, injection, acid bath, forming, washing, drying, adding chitin, desalted water and auxiliary agents in the mixing process to prepare chitin solution ; In the injection process, after the chitin mixed liquid obtained in the filtering process is suction-filtered, the injection trolley adds the chitin mixed liquid obtained in the filtering process into the spinning stock solution according to the ratio of 20ml:1L through the injection control system.

[0048] Said mixing, grinding, and filtering refer to mixing chitin with desalted water at a mass ratio of 1:22 at room temperature, then adding 20% additives according to the mass ratio of chitin to fully mix, and grinding to a particle size of ≤ 20u of suspended solids.

[0049] Described auxiliary agent comprises dispersant CH-12, AMP-95, polyethylene glycol, defoamer 642, preservative CI-15, dispersant CH-12, AMP-95, polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com