Tapered carbon nano tube and electronic source used for the same

A carbon nanotube, electron source technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problem of limitations in increasing the voltage, and achieve the effect of reducing the loading voltage, high resolution, and small energy amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

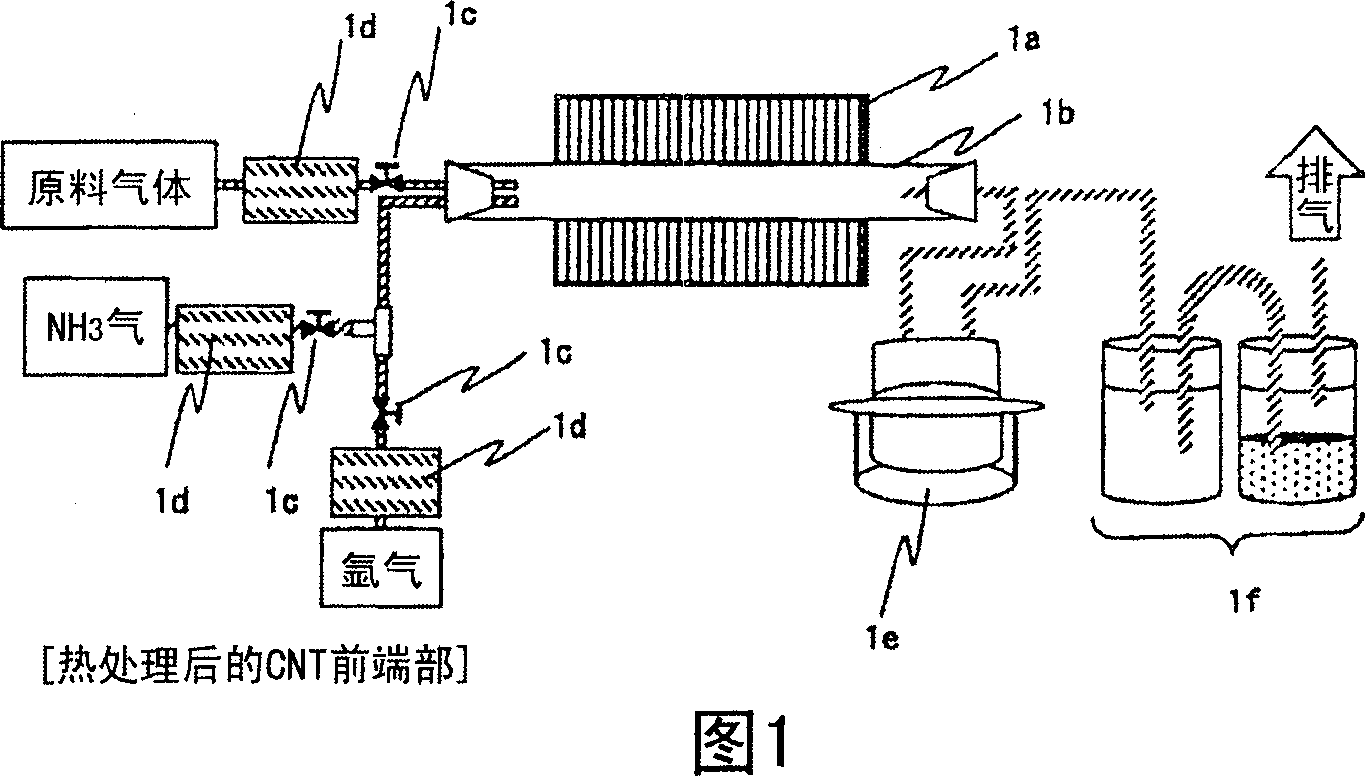

[0033] (Manufacturing method of carbon nanotubes)

[0034] Typical methods for producing carbon nanotubes include an arc discharge method, a laser rubbing method, and a vapor phase (CVD) method.

[0035] The arc discharge method is to prepare two graphite rods with a diameter of 10 mm and a length of 100 mm, and connect the end faces of each other. The above two graphite rods are arranged so that their central axes coincide with each other, leaving a gap of about 1-2mm after contact. It is also possible to apply a DC voltage in this state to discharge the arc, but there is a possibility that gas components in the air may be mixed in and contaminate the carbon nanotubes.

[0036] Therefore, the interior of the test piece chamber in which the above-mentioned graphite rod is installed is evacuated by a rotary pump to remove the above-mentioned gas components. Then, an inert gas such as He or Ar is introduced, and the pressure is adjusted to approximately atmospheric pressure. ...

Embodiment 2

[0058] Next, as shown in FIG. 3, the above-mentioned process is repeated twice and heat treatment is performed. The heat treatment temperature and time are the same as those in Example 1 above. As a result, the tip shape becomes an acute angle again. On the other hand, a part of the carbon nanotubes is cut off by multiple times of heat treatment, and the overall short carbon nanotubes can be obtained.

[0059] The crystallization of the carbon nanotubes starts centering on the above-mentioned defective portion. If there is a missing part on the carbon nanotube, it may break or the like from this part. By repeating the heat treatment twice, carbon nanotubes with a length of 10 μm or more were crystallized in 2 to 3 places, and the length sometimes became half or less.

Embodiment 3

[0061] Secondly, the effect of heat treatment on the length of carbon nanotubes is discussed. The time for maintaining the heat treatment temperature on the low temperature side in the process of Example 2 was changed, and the heat treatment was repeated twice, and the change in the length of the carbon nanotubes after the heat treatment was measured. 500 samples were checked manually, rounded to one decimal place, and classified into 1 μm, 2 μm, 3 μm, 4 μm, 5 μm, 6 μm, 7 μm, 8 μm, 9 μm, and 10 μm or more, and counted.

[0062] The results are shown in FIG. 4 . Before the heat treatment, there were many 10 μm or more, but the heat treatment increased the number of less than 10 μm. In the case of holding at 600° C. for 3 hours, many carbon nanotubes with a length of 2 μm were obtained compared with the case of 1 hour. In addition, as a result of holding at 600° C. for 6 hours, almost the same number of carbon nanotubes of 1 to 4 μm was obtained.

[0063] Therefore, when long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com