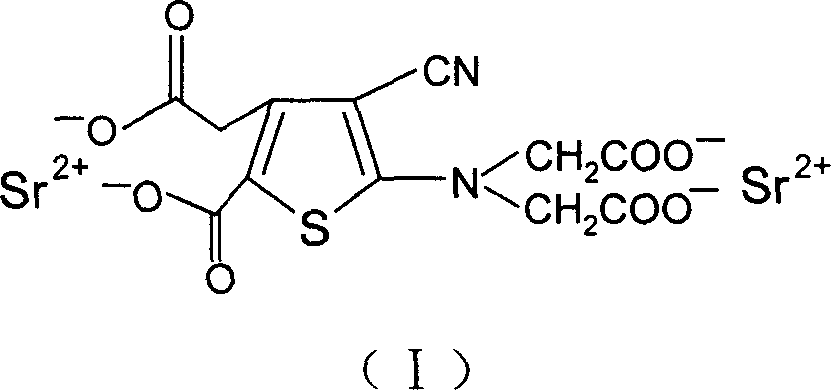

Process for preparing strontium ranelate tetrahydrate

A technology of strontium ranelate and tetrahydrate, which is applied in the field of preparation of strontium ranelate tetrahydrate, can solve problems such as difficulty in dissolution, unexplained chemical purity, easy moisture absorption and weathering of strontium ranelate, etc. Achieve high stability, high chemical purity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Pour strontium ranelate tetrahydrate (30.0g, 43.6mmol, content 85%) and 100ml deionized water into the reaction flask, stir and suspend at 25°C, add dropwise 6N sulfuric acid solution to adjust the pH=1.0, the solid is completely dissolved, and the obtained The clear liquid was washed with ethyl acetate (30ml×3) times, the layers were separated, the water layer was filtered, 6N sodium hydroxide solution was added dropwise to the filtrate to adjust the pH=9.0, stirred at room temperature for 3h, filtered, the solid was washed with acetone (30ml×2) Wash and dry under reduced pressure to obtain 19.1 g of strontium ranelate tetrahydrate (yield: 75%, purity: 99.2%, content: 98.9%).

Embodiment 2

[0017] Pour strontium ranelate tetrahydrate (30.0 g, 42.1 mmol, content 82%) and 100 ml of deionized water into a reaction flask, heat to 40-50 ° C and add 6N hydrochloric acid solution dropwise to adjust pH=2.0, and the solid is completely dissolved. The obtained clear solution was washed with ethyl acetate (30ml×3) times, the layers were separated, the water layer was filtered, 10% ammonia solution was added dropwise to the filtrate to adjust the pH=10.0, stirred at room temperature for 5h, filtered, and the solid was washed with acetone (30ml×2 ), and dried under reduced pressure to obtain 19.7 g of strontium ranelate tetrahydrate (yield: 80%, purity: 99.4%, content: 99.2%).

Embodiment 3

[0019] Pour strontium ranelate tetrahydrate (30.0g, 44.6mmol, content 87%) and 100ml of deionized water into the reaction flask, heat to 40-50°C, add 6N hydrochloric acid solution dropwise to adjust the pH=3.0, and the solid is completely dissolved to obtain The supernatant liquid was washed with ethyl acetate (30ml×3) times, the layers were separated, the water layer was filtered, and saturated sodium carbonate solution was added dropwise to the filtrate to adjust the pH=8.0, stirred at room temperature for 4h, filtered, and the solid was washed with acetone (30ml×2) Wash and dry under reduced pressure to obtain 20.1 g of strontium ranelate tetrahydrate (yield: 77%, purity: 99.4%, content: 99.1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com